Danish Stages

Denmark: A journey through innovation and sustainability

The igus:bike worldtour has arrived in Denmark – a country where cycling culture meets modern architecture, and where the tranquility of nature blends with the dynamism of the city. This journey takes us through Denmark’s varied landscapes on igus bike – a bicycle made entirely from recycled plastic that requires no lubrication or maintenance.

We start our tour at igus’ Danish office in Vejle, where innovation and sustainability go hand in hand. From here, we cycle to Vejle Harbor to admire the modern architecture, including the impressive Fjordenhus, which rises directly from the water. Our route then takes us through the historic **Dyrehave**, where undulating forest trails and wildlife create an idyllic setting for the trip.

Our journey continues to one of Denmark’s most iconic places: Legoland in Billund. Here, in a world of Lego bricks, we experience how creativity and imagination can create fantastic worlds. It is the perfect example of how small components can form a large, impressive whole – just like the recycled materials that make up our igus:bike.

Back in Vejle, we take a final trip past the city’s architectural landmark, Bølgen. The wave-shaped buildings stand as a symbol of Vejle’s modern urban development and give us the perfect view of the water before we continue our journey.

Denmark, and especially Vejle and Billund, is the ideal place to test the strength of igus:bike in everyday life. With beautiful landscapes, modern urban environments, and bike-friendly roads, Denmark proves that sustainable transport is the way forward.

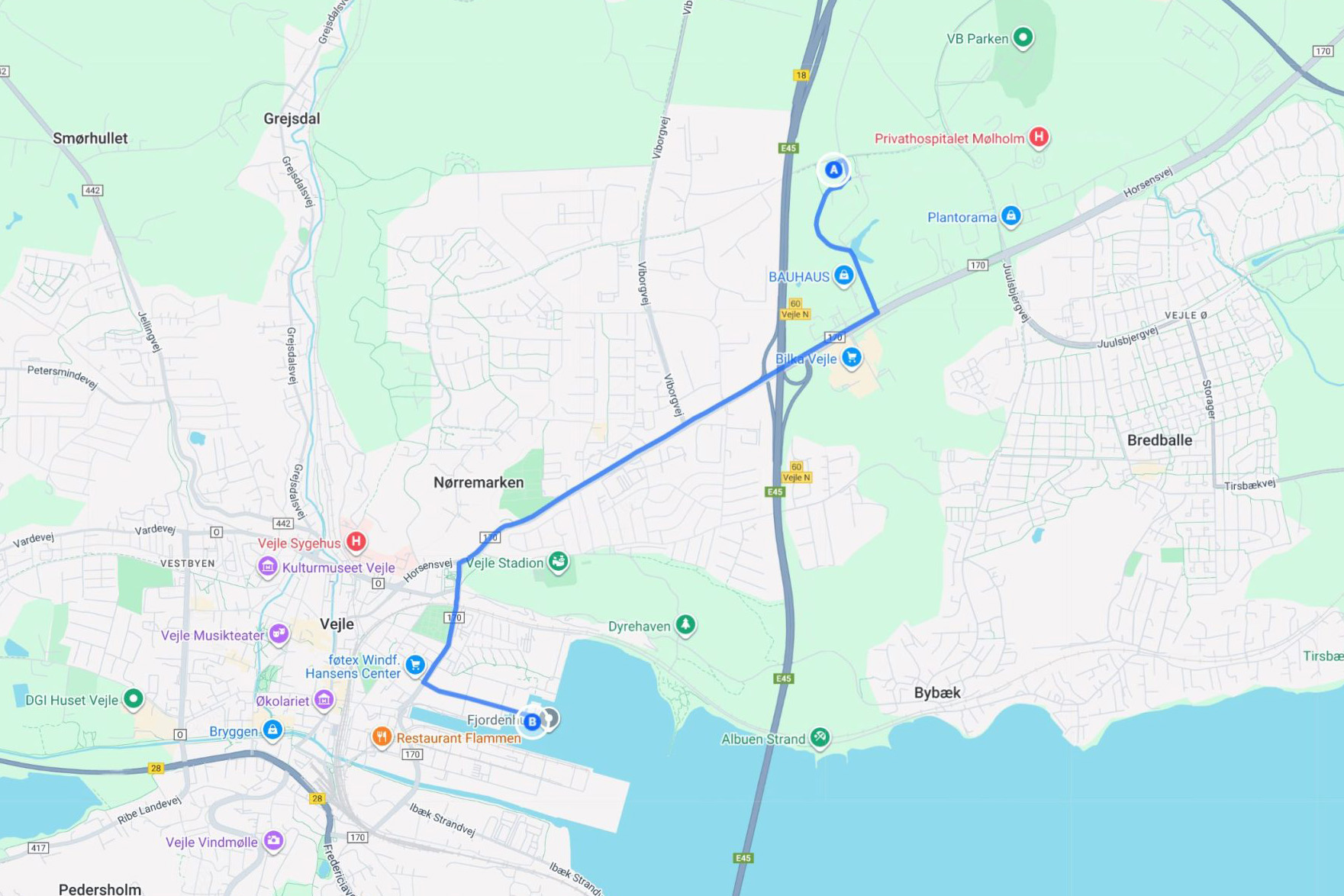

Stage 1 Welcome to igus Denmark

Date: 25. August 2025

Starting Point: igus ApS, Lysholt Allé 8, 7100 Vejle

Destination: Fjordenhus, Havneøen 1, 7100 Vejle

Distance: 10 km

Rider: Henrik Borch

After months of anticipation, the igus:bike has arrived in Denmark, kicking off a tour across five stops. The journey starts in Vejle, where Henrik Borch, country manager since 2017, welcomes us.

Henrik has been pivotal in igus Denmark’s growth, contributing to its success. The tour begins at the Vejle office and explores nearby forests, featuring deer sightings, before reaching the fjord with iconic landmarks like Bølgen and Fjordenhus.

Next stop is Billund, home to LEGOLAND®, the LEGO® factory, and an igus customer. This tour celebrates innovation, sustainability, and partnerships, showcasing technology and the circular economy in action.

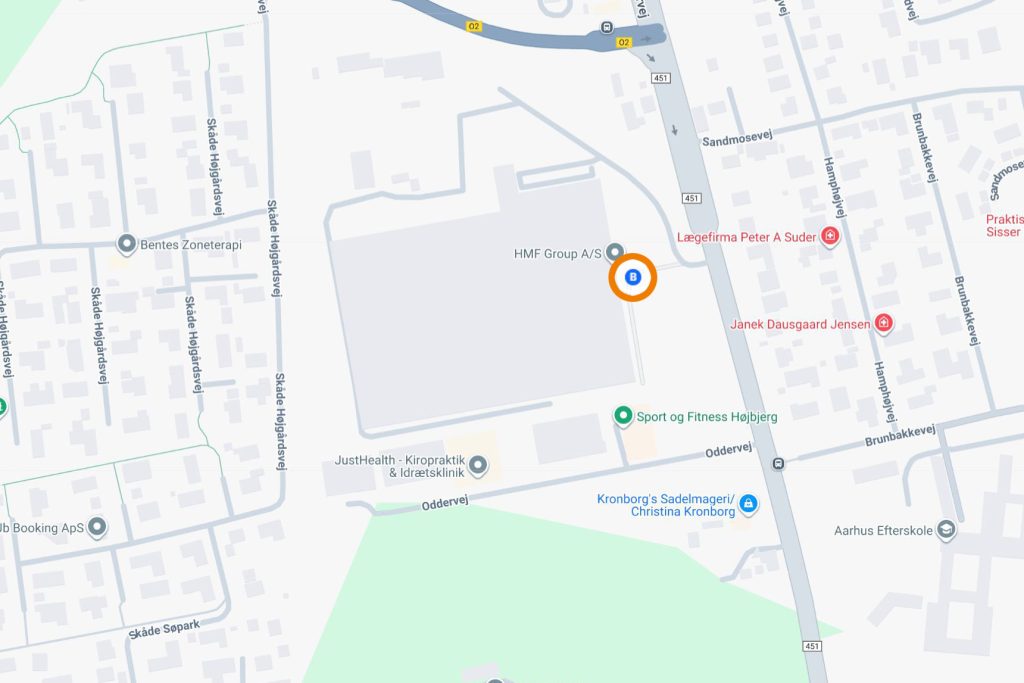

Stage 2 Visit to HMF in Højbjerg

Date: 25. August 2025

Starting Point: HMF Group, Højbjerg

Destination: HMF Group, Højbjerg

Distance: 0,5 km

Rider: Mads Johansen

On the second stage of the Danish igus:bike Tour, Mads Johansen, Key Account Manager at igus Denmark, takes his bike to Højbjerg near Aarhus. Here we visit one of our long-standing customers, HMF Group, which has been one of the leading manufacturers of truck cranes since 1952.

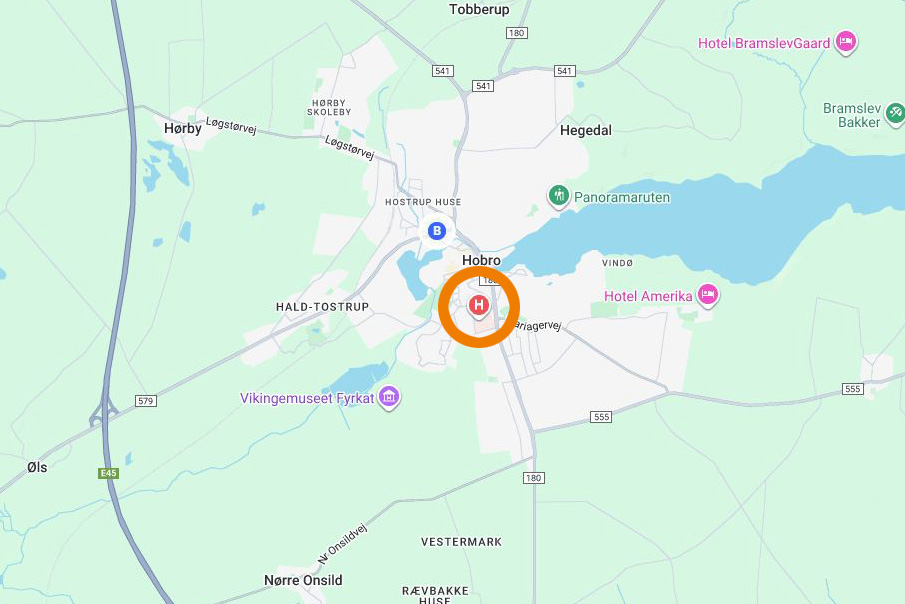

Stage 3 PowerCon – our partner in Shorepower

Date: 25. August 2025

Starting Point: PowerCon, Hobro

Destination: PowerCon, Hobro

Distance: 0,5 km

Rider: Mads Johansen

On the third stage of the igus Bike Tour, we visit PowerCon and meet the company’s CFO, Mr. Peter Castberg Knudsen who helped found the company.

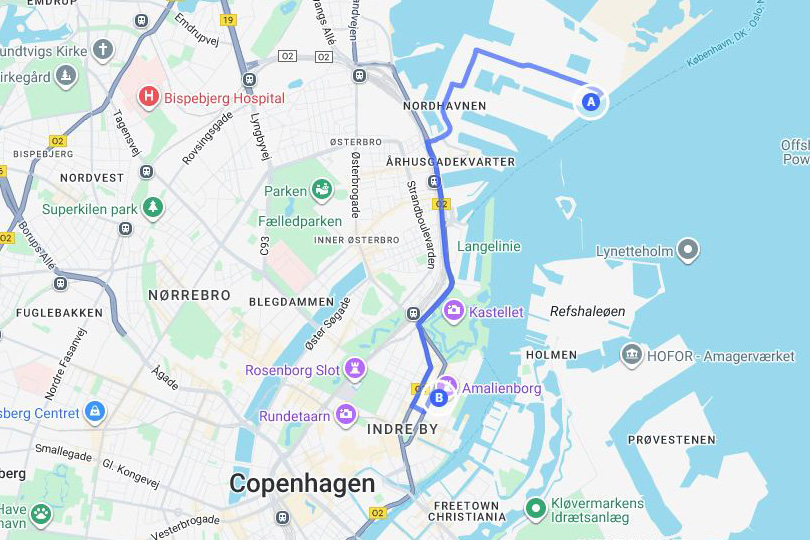

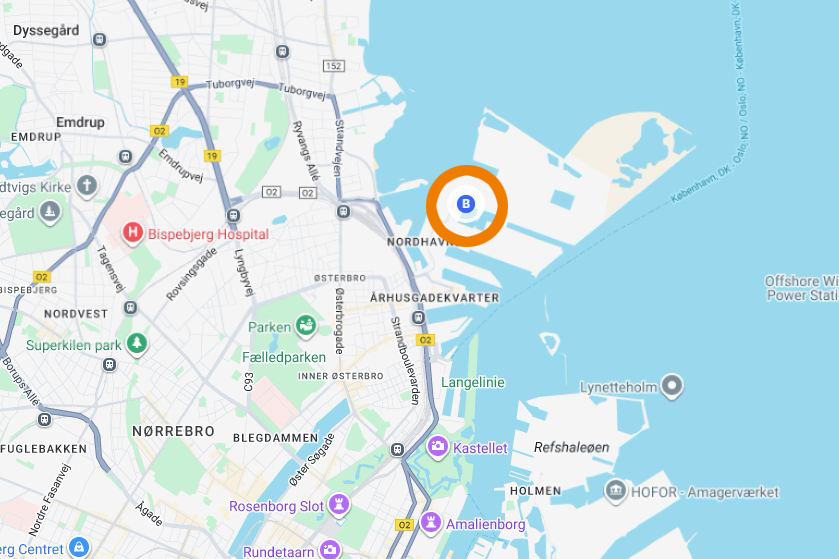

Stage 4 A royal bike ride in Copenhagen

Date: 26. August 2025

Starting Point: The Little Mermaid, Copenhagen

Destination: Amalienborg Palace, Copenhagen

Distance: 6,4 km

Rider: Mads Kjøller

On the fourth stage of the igus:bike Tour, we head for Denmark’s capital, Copenhagen – a city steeped in history, culture, and iconic sights

Stage 5 Innovation in the construction industry with COBOD International

Date: 26. August 2025

Starting Point: COBOD International, Copenhagen

Destination: COBOD International, Copenhagen

Distance: 0,1 km

Rider: Mads Kjøller

On the fifth and final stage of the Danish igus Bike Tour, we visit one of our most exciting and innovative customers, COBOD International. COBOD has made a name for itself worldwide with its groundbreaking 3D construction printers, which make it possible to print entire buildings. Their 3D printers follow a predefined path based on a 3D model to build structures layer by layer, supported by an advanced material delivery system that ensures accuracy, consistency, and efficiency throughout the process.