The HACCP concept for companies in the packaging and food industry

igu-blog-adm | 12. October 2021

In order to be able to guarantee the safe handling of food products, manufacturing companies nowadays require a number of hygiene concepts, including the HACCP concept. The acronym refers to the expression Hazard Analysis and Critical Control Points and is generally known in German as Gefahrenanalyse kritischer Kontrollpunkte. Basically, the HACCP concept is used for self-monitoring by food companies in order to protect the product and the consumer. The concept is based on flexibility – every company can and should apply the concept to its own processes and structures. In this context, the HACCP concept is one of many cornerstones of food safety in the food industry. It is part of the legally regulated system that enables quality assurance in the production and handling of food.

What exactly is the HACCP concept?

The concept of food safety is intended to ensure that businesses subject to hygiene legislation demonstrate appropriate food handling practices. The basic components of the HACCP concept consist of incoming goods inspection, temperature monitoring, cleaning and disinfection plan, pest control, staff training and traceability. Here it is important not only to inspect the individual components, but also to document the results of the check at all times.

Among other things, the components of the hygiene concept stipulate that delivered or purchased goods must be checked for their condition, best-before date and temperature. A fixed cleaning and disinfection schedule for the facilities and operating rooms must then be established.

How is the HACCP concept implemented?

To establish a HACCP-based procedure, you can use the 7 principles:

- Hazard analysis, in which hazards are identified.

- Identify the critical points of the process stage(s).

- Establish limits for these critical points.

- Establish and implement effective monitoring procedures.

- Determination of corrective actions in case a critical process step runs uncontrolled.

- Establish periodic verification procedures to determine compliance with points 1-5.

- Preparation of documents and records to demonstrate compliance with the requirements set out in points 1 to 6.

The hazard analysis

Hazard analysis involves an identification of all possible hazards that may arise at any stage of food production. The types of hazards can be physical, chemical, or biological in nature that make food consumption dangerous to humans. Here, the chronological sequence of all process stages is considered, as well as the production sequence, in order to determine the probability of occurrence of these hazards.

Critical points, limits and monitoring procedures

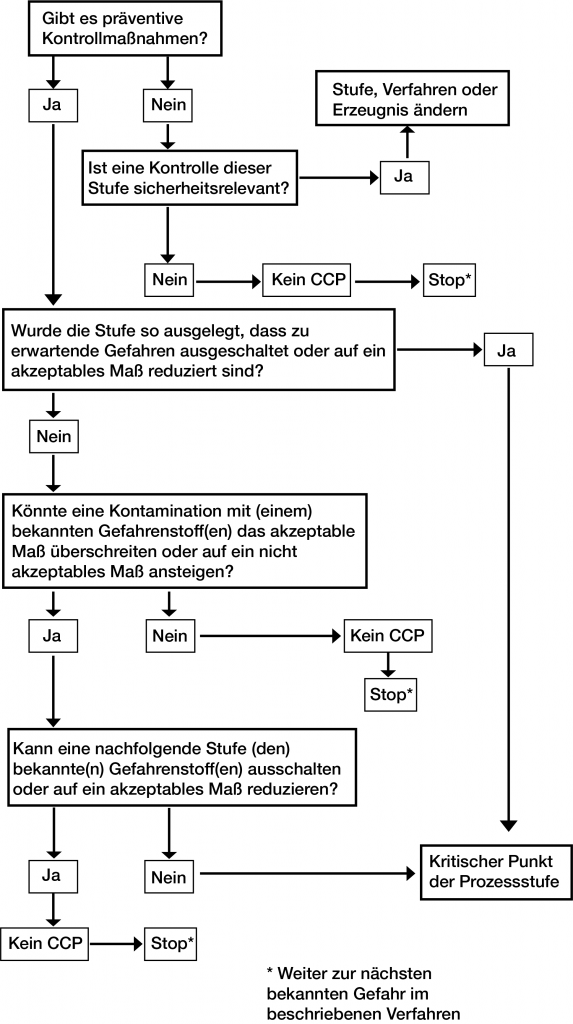

Critical points are understood to be those points at each process stage where a hazard may occur. Here it is advisable to create a decision tree that helps to identify the critical points of the process stages.

Limit values are the outermost values related to the safety of the product. These should be measurable as fixed parameters in order to make critical points identifiable. The limit values are accompanied by monitoring procedures that allow a loss of control to be properly detected. Measurements of a monitoring procedure should be carried out at appropriate, regular intervals.

Corrective actions and documentation

Corrective action is taken as soon as a deviation from the critical limits becomes apparent. The measures should be determined in advance in order to be able to implement them immediately in the event of limits being exceeded or falling short of the limit values.

The documentation concerns all principles of HACCP, because these must always be traceable and verifiable.

TÜV Nord offers a detailed overview of the 7 principles of the HACCP concept at this place.

Food safety and plastics – do they really go together?

Absolutely. The food industry often benefits from components made of plastic. Be it a lower weight, a better chemical resistance than stainless steel or a low moisture absorption. Also at igus many elements made of high-performance plastic prove their worth with their solid lubricants. This means there is no lubrication of the components with lubricating oil, which in turn minimises product contamination.

In the field of hygienic design, it does not always have to be stainless steel but can – as reported here – also combine other materials and food safety measures.

The article is based on the Guide to the implementation of HACCP-based procedures of the European Commission and Article 5 of Regulation EC 852/2004.