Which ball bearing is suitable for high speeds?

Patrick Czaja | 2. June 2022

Deep groove ball bearings according to DIN 625 standard are the most commonly used ball bearings in industry. Depending on the application, plant operators have different requirements for the installed machine components. For deep groove ball bearings, for example, the possible speeds per minute are usually important. Which ball bearing is suitable for high speeds? And that even made of plastic? xiros is the answer.

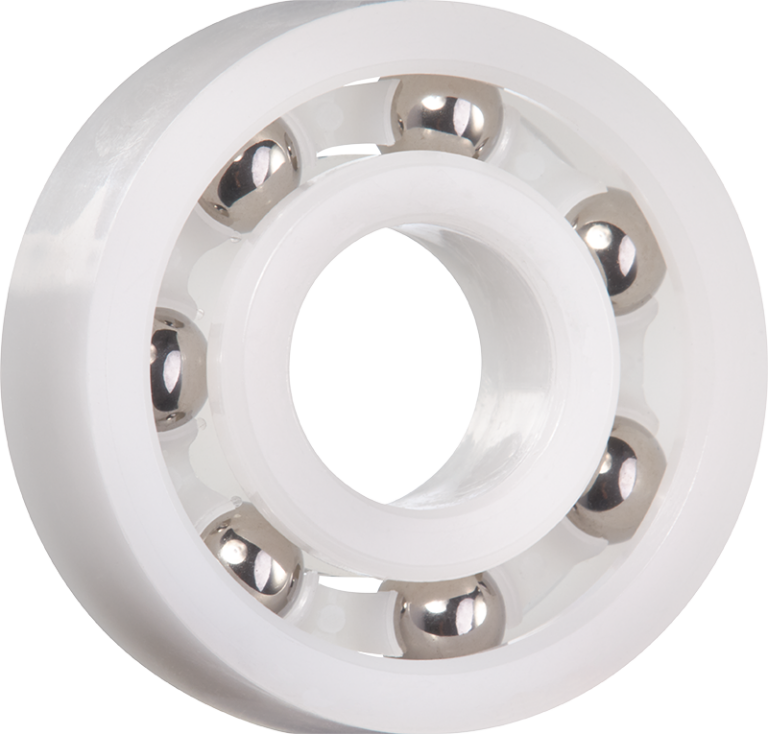

Our deep groove ball bearings made from the in-house-developed high-performance plastic xirodur B180 are a true all-rounder in industry. With the longest service life of all xirodur materials, low coefficients of wear and good chemical and medium temperature resistance, xirodur B180 deep groove ball bearings have been successfully used in customer applications for many years. Depending on the type, speeds of up to 4,500rpm are possible. In addition, the ball bearings impress with their smooth running and resistance to media, temperature and corrosion. And all this without a single drop of lubricating oil. Because our ball bearings are 100% lubrication-free.

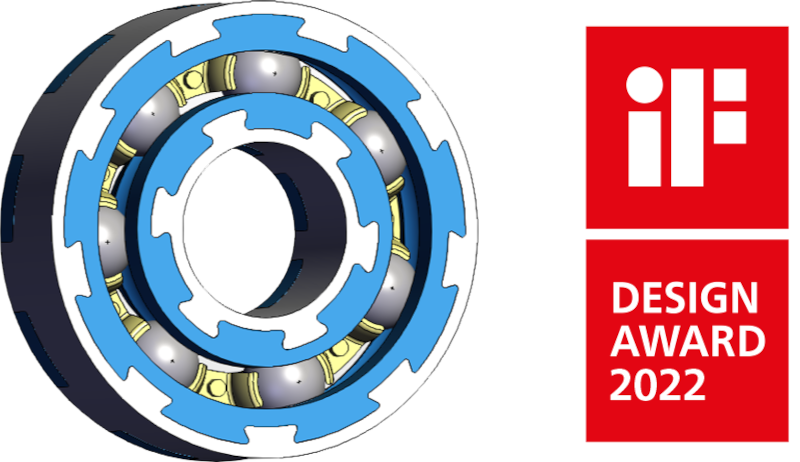

The expertise and years of research are also reflected in a very special product: the two-component ball bearing, which was even awarded the IF-Design Award 2022. True to the motto “Hard shell, soft core,” we have innovatively combined materials to develop a lubrication-free and maintenance-free ball bearing that runs quietly and remains dimensionally stable even at permanently high speeds. The xirodur D180 used is responsible for the low noise emissions.

To keep it dimensionally stable, it is combined with the hard shell. Since the soft material is poured into the hard shell of both races, the balls always run on the soft xirodur D180 during rotary movement and are supported by the shell. The special design with undercuts also has a task. This ensures better adhesion of both materials and additional stability. The design is rounded off by a wear-resistant cage made of iglidur J3, which keeps the balls at a distance.

Would you like to find out more? https://www.igus.eu/info/xiros-two-component-ball-bearing