How do I mount ball bearings?

Patrick Czaja | 29. October 2021

If the metal ball bearing is a fixed or floating bearing, the outer and/or inner ring are firmly connected to the shaft or housing. The easiest way to mount this type of bearing is to press it into place. However, certain tolerances are necessary in the dimensions for the shaft and housing.

In general, it can be assumed that the rotating ring is executed in the firm fit, a so-called interference fit, and the stationary ring is made in the loose fit, the clearance fit up to transition fit. If there is an impact on the bearing, both the rotating and stationary ring will be executed in a firm fit. Easy assembly and disassembly of the bearing and preventing the ring from spinning is essential. Furthermore, the inner ring can also be pressed with a clamping sleeve or clamped between a nut or clamping screw.

In the thermal process, or also known as heat shrinking, the metal ball bearing is usually heated to a temperature of up to 125°C by induction. As a result, the entire bearing expands and can be pushed onto the cold shaft without any problems. After the ball bearing has cooled down, it contracts resulting in an extremely tight fit on the shaft.

But what does the mounting/installation and the measuring of the xiros plastic ball bearings look like at igus? We are one of the few manufacturers in the world to produce the ball bearing rings by injection moulding . This offers users the following advantages:

- High wear resistance due to the shape under high pressure

- Homogeneous material distribution

- Cost-effective production meaning economical prices

- Simplification of ball bearing installation

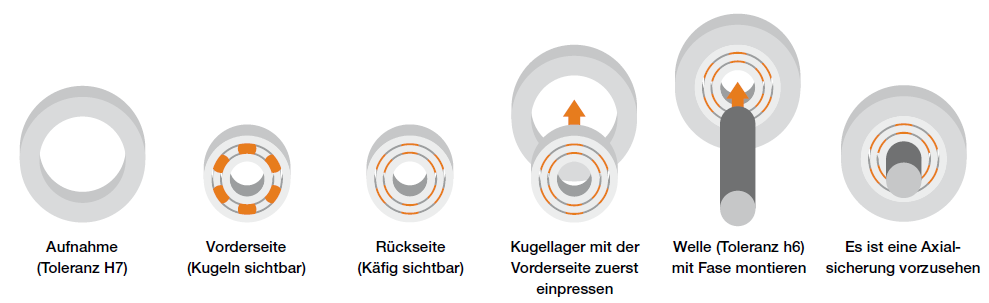

Due to this manufacturing process, different rules apply for both measurement and mounting compared to metallic or ceramic ball bearings. The outer ring of the plastic ball bearings is conical. This simplifies the installation in a suitable housing (with the narrow side first). After press-fit into a housing machined to a H7 tolerance, the bearing clearance is reduced. Therefore, the ball bearings must be measured over the entire width; starting at an angle of 90° from the injection point.

Do you need more information about our plastic ball bearings? Then simply take a look at our info page: https://www.igus.eu/info/ball-bearings-technology