e-spool – the alternative to a cable drum on EOT cranes

Jens Göbel | 15. July 2020

As already described in my blog post on cable routing for lifting devices on indoor / EOT cranes, lifting devices sometimes require their own power and control supply. Ion order to carry out the lifting movement of the lifting device, the cables must either be coiled up on a cable drum or stowed away safely, with the help of an energy chain, in a special basket.

However, there are several applications and lifting device designs that simply have not sufficient space to mount a collection basket for our chain. If for such cases the use of a classic motor drum solution is the first thing that comes to your mind, then you are wrong.

Before turning to the corresponding chain solution for such applications, I briefly want to take a look at the motor cable drum again.

Motor cable drum:

For the maintenance team, such a cable guidance system requires regular maintenance work, with the corresponding downtimes of the crane. Which components of the motor cable reel require this frequent maintenance effort? Firstly, such a system contains a slip ring, secondly either an integrated motor or at least a spring system. Each drive type ensures that the cable is kept under constant tension during the winding and unwinding process. The tensile stress puts a strain on the cable(s) used and has a negative impact on the cable lifetime.

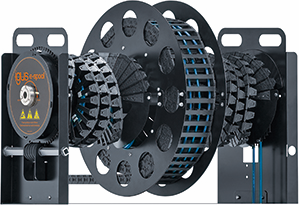

e-spool:

When looking at the e-spool for the first time, one may wonder in how far this product with an integrated energy chain differs from a motor cable drum and its maintenance requirements. Firstly, the e-spool uses an energy chain to absorb any tensile stress. The cables guided inside the chain are therefore not exposed to tensile loads, which as a positive effect on the cable service life. Secondly, the e-spool system is completely slip ring free. Thus, eliminating the use of a maintenance-intensive component. With the e-spool, also other media, like air or liquid hoses, can safely be guided. The system is, however, limited to cable or hose diameters of maximum 17mm in diameter. As no sliding contact is used with the e-spool, cables or hoses are routed through the system without any interruption. This allows for cable or hose modifications or exchanges at any time. One thing that the e-spool has in common with some motor cable drum types is the retention spring, ensuring the constant retention force on the chain. This component requires a regular maintenance and has a limited lifespan. The retention spring also limits the maximum travel length (chain extension) to a length of 14 meters. If you prefer a retention spring free solution or need a longer extension length, the e-spool power might be the right choice.

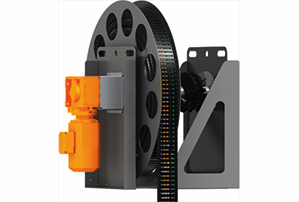

e-spool power:

The motor-driven e-spool is so far identical to the normal e-spool already described above, with the only difference, that the retention spring is replaced by a motor. This naturally includes all maintenance steps and intervals that are necessary for a trouble-free operation of the electrical motor. The motorized version enables travel lengths of up to 25 meters.

Cables:

As for all energy chain applications, but especially for e-spool applications, only cables specifically designed for the use inside an energy chain should be used, as for instance our chainflex product line. For e-spool applications we recommend the use of cables with a TPE outer jacket and for shielded cables even the use of our torsion approved cable line CFROBOT.

Assembly:

For the assembly, the laying of cables inside the e-spool and tightening the spring, we have put together some useful information in a video on our website.

Application examples:

If we have caught your attention with our e-spool as a modern cable guidance solution, but would still like to see where and how it has been used in other installations, then have a look on our website. You will find application details ranging from stage technology, to automation and vertical movements.

On our website you will find further examples and solutions for the cable guidance on EOT cranes, as well as the free softcopy of our EOT crane brochure.

We did not answer all your questions, or you have an application you would like to discuss with us in more detail? Make an appointment for a virtual consultation now

ABCOEngineers

Really a very helpful article thanks for sharing and keep on sharing!

ABCO Engineers is the Largest Crane Suppliers In Bangalore,Mangalore, Belgaum. Abco Engineers are the best EOT

Crane Manufacturers in Bangalore,Karnataka. ABCO provides Cranes with Excellent Quality and the Wide Range of

Crane services in Bangalore,Mangalore, Belgaum.Contact today for CompleteCrane services in Bangalore

karnataka.

Read more: https://www.abcoengineers.com/