How is condition monitoring of the energy supply on container cranes implemented?

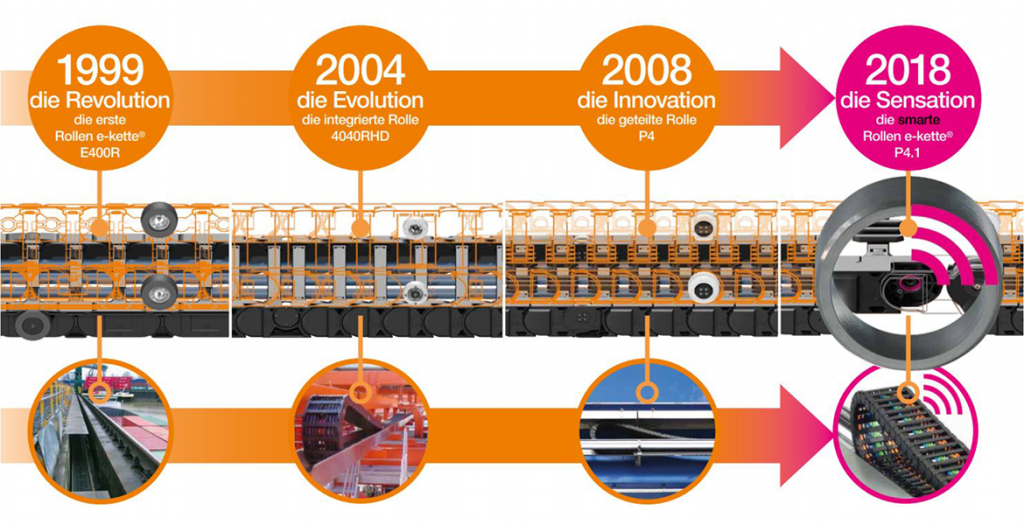

More than 25,000 igus energy chains move over long distances every year, whether in STS cranes, storage and retrieval units or linear robots. In all these areas of application, customers around the world rely on the tough, modular igus energy chain systems. In the latest development stage, maintenance-free tribo-polymer plain bearings considerably lengthen service life. In addition, the new P4HD can be equipped with smart monitoring sensors that, for example, record wear or the pulling or pushing movements continuously and/or detect irregularities. They can be used to trigger alarms or maintenance recommendations, which are communicated with a radio module. In order to prevent a crash, the associated drive can be shut down automatically when it exceeds a prescribed power level. The sensor for continuous condition monitoring is integrated into a standard side section of the chain, but this does not restrict the usable inner width in any way.