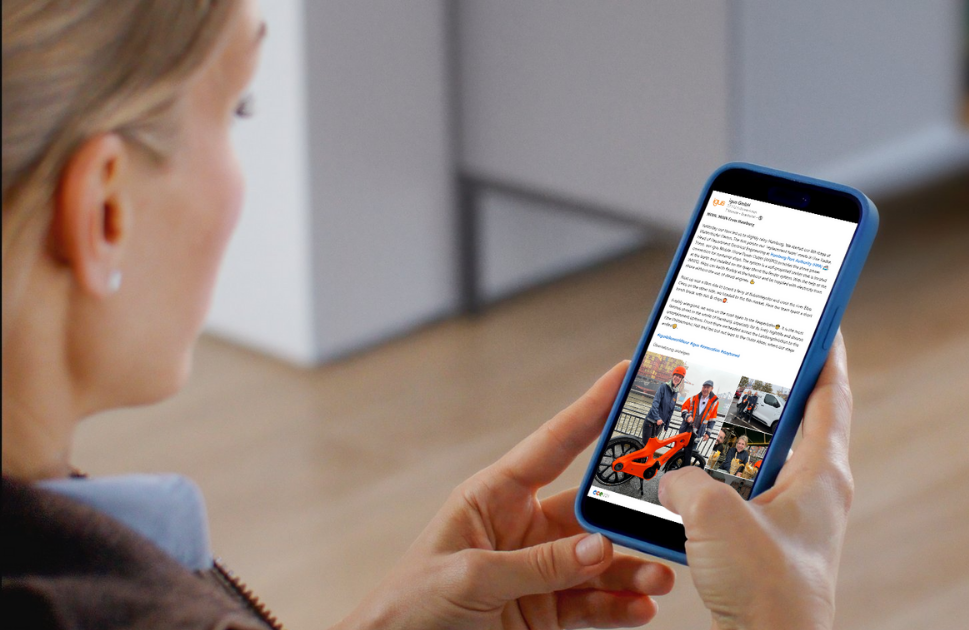

The igus:bike world tour

We are celebrating 60 years of igus with a very special journey!

Since our anniversary, October 15, 2024, we have been on a world tour

with our igus:bike. Over the next 12 months, we want to ride a total

of 6,000 kilometres. Touring different stages through major cities,

along rivers and beaches and visiting several customers applications