Which plain bearing is suitable for the commercial vehicle industry?

igu-blog-adm | 12. September 2022

The development of electric vehicles (BEV, PHEV, HEV) and vehicles with fuel cells (FCEV) is in vogue thanks to their low-emission use. Statutory requirements and higher energy costs are the reason why OMEs and suppliers place particular emphasis on the sustainability and lightweight of their designs when developing new products.

With the help of lightweight designs, the weight of vehicles can be reduced and the range can be optimised at the same time. Developers and designers benefit in particular from lightweight components with minimal installation space. By using igus® plain bearings, weight and installation space are effectively reduced and used. Supposed minor weight improvements in the bearing area therefore help to implement legal requirements and optimise the vehicle range.

However, the requirement profile of the commercial vehicle sector extends far beyond legal requirements. For example, high loads, dirt, humidity and fluctuating temperatures are major challenges for components and systems. With all this in mind, forwarding agents cannot afford unscheduled maintenance and the associated downtime.

The iglidur® M260 bearing material, developed for heavy loads and harsh environments, is considered maintenance-free thanks to integrated solid lubricants. Additional external lubrication with grease or oil is not necessary. Perfect for use in commercial vehicles. In practice, thick-walled plastic bearings in particular have the advantage of being able to replace metallic solutions without making dimensional changes to the shaft and housing. In addition, iglidur® M260 plain bearings offer the following advantages:

- Lubrication-free and maintenance-free

- Excellent wear properties in combination with HR carbon steel shafts

- Robustness against impact loads and vibrations

- Low moisture absorption

- Low coefficient of friction and wear

- Corrosion-free even in salt spray tests

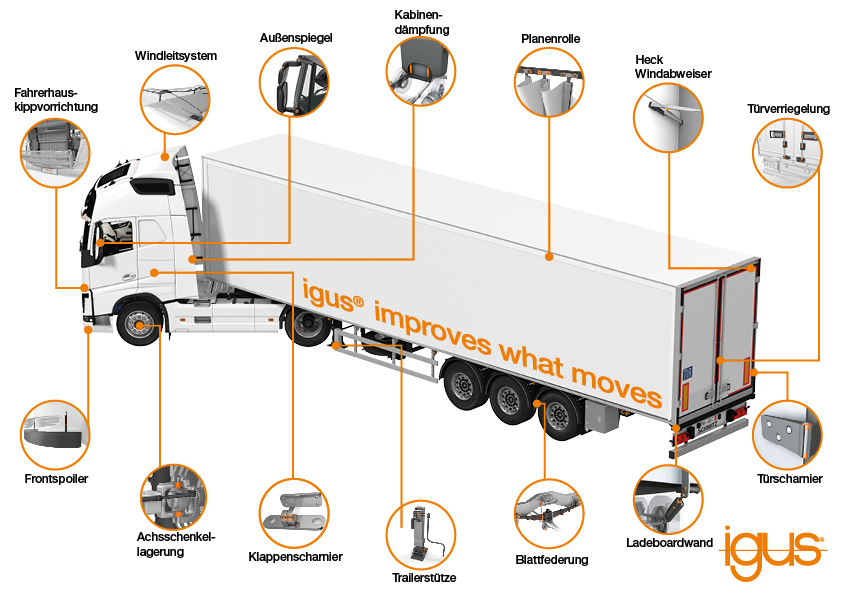

It is used for heavy-duty sliding applications, e.g. trailer supports. Other lorry applications for igus® products include door hinges, loading board walls and tarpaulin rollers.

In order to further advance the topic of sustainability and emissions reduction, igus® presented its four iglidur® ECO materials (ECO- H, A180, P, G) at its new product presentation this year. These compounds consist of 97% to 100% regranulated materials. These include sprues from previous productions, which are added to the production process a second time. With all of this, you still have the option of calculating the service life.

To support this, igus® has been displaying the transparent CO2 footprint in the online shop since summer 2022. For our top 16 materials, we will support you in presenting the imitated CO2 values of our bearings transparently, across the entire manufacturing process. This will enable you to quickly and easily select your individual bearing with the lowest CO2 footprint. At the same time, we are fully focused on further reducing our CO2 balance across the corporate group.

__________________________________________________________________________________________

Have I sparked your interest?

I would be happy to provide you with free samples, answer your questions, and show you further advantages for your specific application.

__________________________________________________________________________________________

igus commercial vehicle solutions: Machine elements: Lorry and trailer solutions (igus.eu)

iglidur® M260 material data sheet: iglidur M260 plain bearings (igus.eu)

I look forward to hearing from you:

Joshua Weigel

Automotive Sales Manager

Phone: +49 (0) 2203-9649-8046

Mobile: +49 (0) 152-58791240

E-mail: jweigel@igus.net

Follow us on: LinkedIn, Instagram, Facebook

Have fun browsing and thank you for your time.

More information: Automotive industry, plastic bearings for automotive interiors, exterior and engine compartment applications.