Thoroughly tested – the test laboratory for xiros® polymer ball bearings

Patrick Czaja | 4. December 2020

Our test laboratory for polymer ball bearings generates the knowledge essential for refinements and new product designs. There is even more benefit to our customers, since we pool our test results and experience in our online tool. They help in selecting the right product for our customers’ individual applications.

Test rigs in the test laboratory

The first part of our blog deals with two of the various test rigs in our test laboratory, where our xiros polymer ball bearings are thoroughly tested. Below is an overview of our test rig for radial deep groove ball bearings and our rotation test rig, including technical data, graphs and images.

Radial deep groove ball bearing test rig

- Test rigs with integrated sensors (DAQ) for simultaneous measurement of wear and load capacity (up to 250N) and various service life and temperature tests

- Max. speed 5,000rpm

- Movement: outer race fixed, inner race rotates

- Installation size: 6000

Lena Woelke, who is responsible for material development of xiros polymer ball bearings, at the radial deep groove ball bearing test rig

DAQ measuring system + heating

Rotation test rig

- Tests at high speeds and low loads (5,000rpm, 10N)

- Ongoing tests with our own xirodur D180 and iglidur cage materials

- Installation size: {N1}

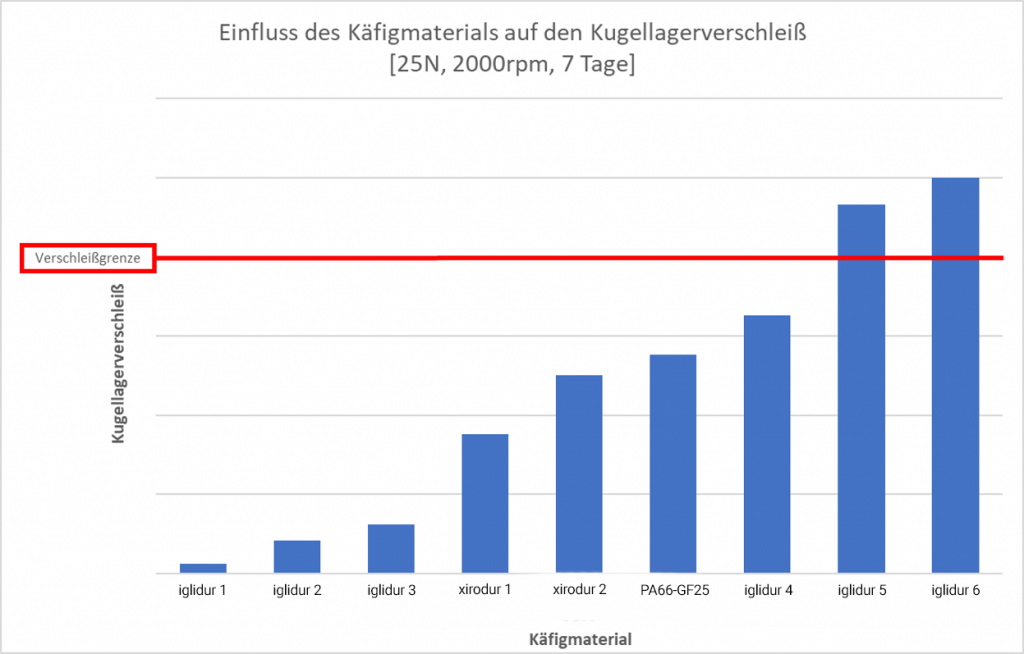

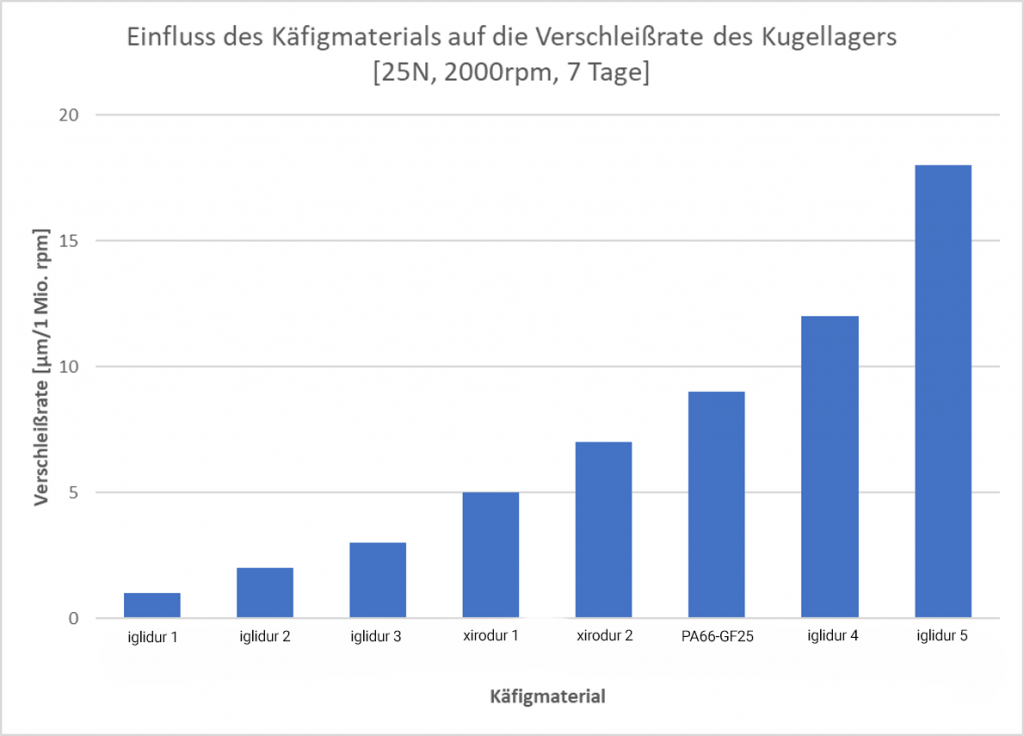

The effect of cage materials on ball bearing wear

The difficulty is that high speeds (2,000rpm, for example) generate high centrifugal forces of the balls. This accelerates the balls outwards. The cage material requires a certain stability, since the cage pockets would otherwise expand, giving the balls more clearance and freedom of movement. Since the balls can no longer maintain the correct position, there is more wear and the bearing fails faster.

We use reinforcement materials to increase cage material stability, and there is sliding friction between the balls and the cage. Solid lubricants improve sliding performance. That is why we use iglidur materials for cages. They contain additives that improve stability and sliding properties.

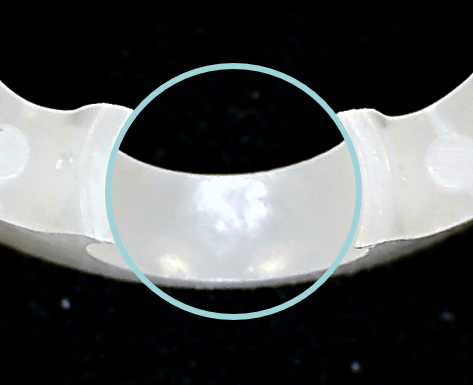

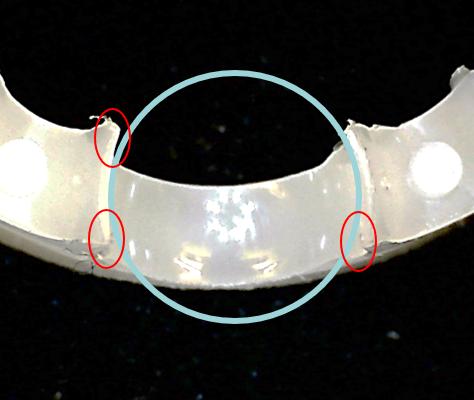

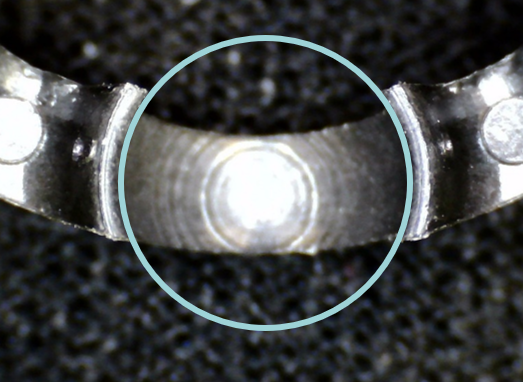

Cage pocket evaluation

unreinforced material, untested

unreinforced material, tested

reinforced iglidur material, untested

reinforced iglidur material, tested