The right lubrication for plastic plain bearings

Lars Butenschön | 7. April 2020

Despite all the greatly varying plain bearing application profiles – from engine block bearing to mountain bike pedals – there is one thing in common: the best lubrication is lubrication that need not be applied. It is often problematic to get grease and oil where they are needed and keep them there. Ensuring that the lubrication system functions well is a great challenge both to design and to the user’s discipline. And lubrication nevertheless often remains indispensable. It allows plain bearings to move smoothly and prevents corrosion, dirt ingress and temperature rises due to friction. The range of available lubrication grease, oil and wax types is huge. Without turning this into an huge advertisement for iglidur plain bearings, let me point out that the practical thing about them is that they require no lubrication. The solid lubricant particles integrated into the material ensure low friction, and its dry operation ensures that there is less dirt and dust at the bearing point in any case. Corrosion is no problem – at least for the bearing itself.

Nevertheless, we at igus keep find ourselves confronted with this issue. That is because even our dry-operation bearings can sometimes benefit from the application of additional lubrication. For instance, some users have eliminated squeaking during the running-in phase with WD-40 and protected their shafts or housing holes against corrosion by adding some wax. I have already dedicated a blog entry to WD-40, so I will tackle lubricating oil this time.

Should you lubricate with grease or oil? And what about penetrating oil?

As a rule, grease and oil is used to lubricate bearings. The difference between the two is primarily the viscosity. This means that oil flows relatively easily (although this varies from oil to oil), while grease tends not to. This high viscosity – that is, a consistency that prevents easy flow – makes grease easier to keep at the bearing point than oil.

Lubricating oil tends to be used to optimise smooth running properties and regulate temperature, and grease is used primarily to provide protection from outside influences such as dirt or moisture. That is why oil-lubricated bearings are usually immersed in oil during operation: the oil flows through the bearing point in a closed cycle and cannot escape. This also explains why the article on WD-40 did not adequately answer the question of plain bearing lubrication. WD-40 is a so-called penetrating oil. It is specially designed for very low surface tension and high viscosity so that it can get anywhere. The same ability also ensures that is doesn’t stay anywhere long. And the little bit that gets to the desired point – that is, to the bearing – dries relatively quickly.

Lubrication of choice: grease

In practical applications, plain bearings that cannot be operated in an oil bath are therefore lubricated with grease. But there are distinctions here, too. Grease is actually not much more than lubricating oil containing thickener and certain additives. Types of oil and thickener can be used in a wide variety of combinations to return various properties. Details about this can be found in the relevant Wikipedia article, which is why I will be brief here.

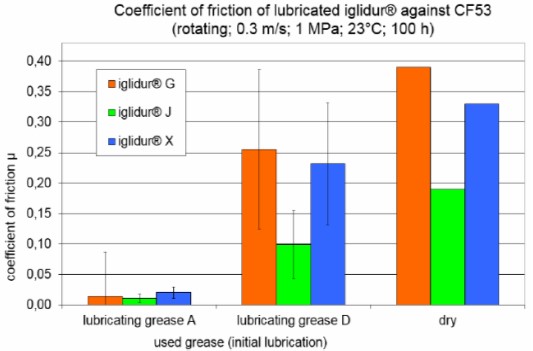

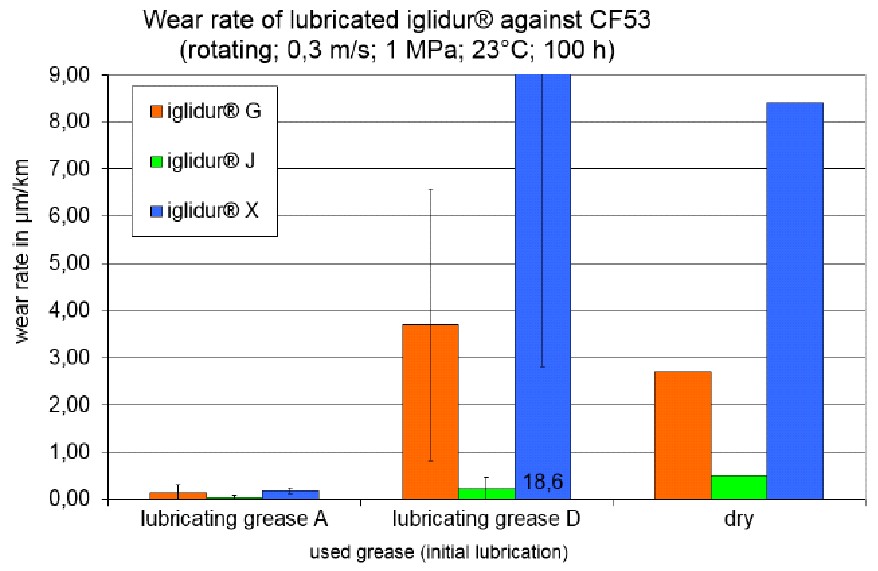

In the igus laboratory, we have analysed two frequently occurring lubricant groups and their interactions with iglidur® materials. Within the groups, substances of the same type from different manufacturers were tested. Tests addressed wear behaviour and effects on friction.

The coefficient of friction is very low, especially for mineral oils with metal soaps. iglidur® J has particularly good results. The coefficient of friction is slightly better for silicone-based grease than for dry operation.

The Group A lubricants also achieved much improved wear results. Surprisingly, however, wear for plain bearings lubricated with silicone oil was actually slightly higher than for dry operation. It should be noted that there was great variation among the results, so that the average results are still better than without lubrication. But there is some question as to whether this difference is noticeable in practice.

Conclusion: grease based on mineral oil delivers the best results

The results shown here match the observations we have made in practical application. Customers with bearing points that are subjected directly to weather, moisture and dirt are especially likely to use grease, and that grease is likely to be mineral-oil-based. Without plugging the product, we often recommend OKS 400 for iglidur® materials. However, good results can be achieved with other greases of similar composition.

Ultimately, however, the decisive factor is the selection of the right grease and the right plain bearing for the application in question and observance of the associated technical parameters.

Do you need help selecting the right grease for your plain bearing application? Or do you have the right grease, but not the right plain bearing? We would be happy to advise you.

Dave

"This low viscosity – that is, a consistency that prevents easy flow"

you have the viscosity backward...Low viscosity fluids shear easily (water, oil, etc) and high viscosity fluids are the ones that "prevents easy flow" - grease, peanut butter, glass, etc.

Lars Butenschön

Hi Dave,

somehow I always found this counter intuitive :D. I guess this time I couldn´t control myself. Thank you for the hint! :).

Kind regards,

Lars

Jim Scott

Plastic bearings were the subject in the title ... but mentioned nowhere in the article. Petroleum-based lubrication in plastic bearings is usually contraindicated. Cut-n-paste article error??