The innovation for cable monitoring: new i.Sense CF.D enables contactless monitoring

Richard Habering | 1. December 2021

A small investment with a big effect: the latest generation of i.Sense CF.D monitoring sensors checks the electrical condition of chainflex cables in e-chain systems – without contact and without interfering with the existing harnessing. As a result, the real-time monitoring of this concept study does not require any sacrificial wires and in combination with the new i.Cee: plus II evaluation module, enables even more efficient predictive maintenance for protection against cost-intensive system failures.

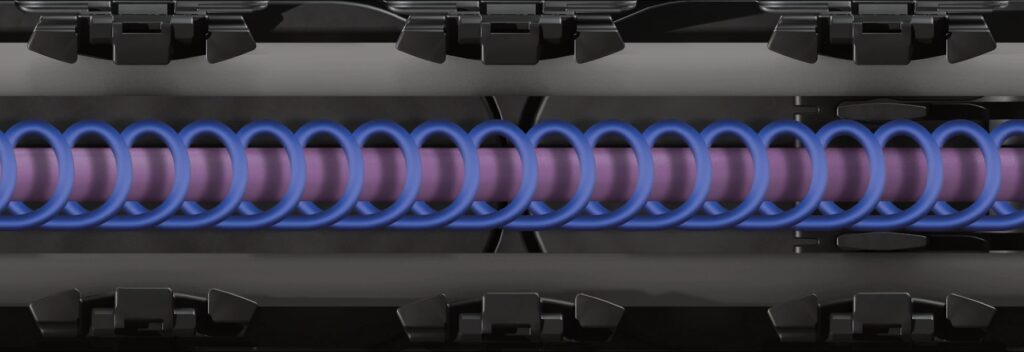

The new sensor electronics system is “clicked” onto both sides of the cable to be monitored, close to the connector and a small measuring wire is wrapped around the cable. This effectively wraps a small “antenna” of 8 cm length around the cable to be measured. Small enough to find space in energy chains in the distribution box on the moving side and in the control cabinet on the fixed end side. The sensors continuously check the cables’ transmission properties during operation.

The monitoring sensors use a high-frequency technology that works without additional sacrificial wires or contacting the existing cores. The sensors reliably measure even the smallest transmission deteriorations of cables and connectors through using this technology. This allows effective predictive maintenance in moving industrial applications in which cables and connectors are subjected to continuous mechanical stress.

Detect faults anytime and anywhere with the i.Cee Dashboard on smart phone or tablet

When data and bus cables approach their wear limit, another innovation comes into play: i.Cee: plus II – a module that connects to the CF.D sensors. A CF.D sensor makes a USB connection to the predictive i.Cee maintenance module. Incipient deterioration of the transmission properties signals necessary maintenance work and adjusts the component service life calculation accordingly. It outputs the measurement results for each individual sensor to a dashboard that users can access through the local network or the internet while on the move with a PC, smartphone or tablet. This means that those responsible can keep up to date at all times and from anywhere in the world and can react quickly to alarm messages received via SMS or e-mail.

Deep Dive: Free online seminar on cable monitoring with smart plastics from igus

I also would like to invite those who would like to find out still more details and backgrounds to this innovation to our online seminar on Thursday, 09.12.21, from 10 am to 10:30 a.m.:

Reliably monitor cables in energy supply applications, extend service life and avoid production downtimes

- What are smart cables?

- How do you use this technology?

- What prerequisites must be fulfilled?

- Where are our customers already using this technology?