Surface pressure and compressive strength – simply explained

Lars Butenschön | 10. June 2020

One encounters these specifications not only in the plain bearing sector, but also in other fields of mechanical engineering. From the maximum compressive strength to the maximum recommended surface pressure. They are often tested according to standards in technical papers and documentation and advertised as “extremely high” in marketing trades. Sometimes the surface pressure seems to be the most important value for the design of a plain bearing, sometimes the compressive strength – after all, the data sheet of the other manufacturer also states compressive strength. And then you just stand there (whether sales consultant or designer). The specifications say 100 MPa compressive strength. The plain bearing manufacturer 100 MPa “maximum recommended surface pressure”. And now?

Interestingly, in everyday life I have received only few conclusive explanations of what exactly a term means and how they differ from each pother. And – quite honestly – the explanations imparted in the mechanical engineering courses were somehow too brief. The explanation must be as simple and plausible as possible. How is the permissible surface pressure determined? And why does it deviate from the compressive strength of the material? Do we have to consider both? Surface pressure AND compressive strength? It’s a mystery.

Compressive strength – what is that?

Simply put, the maximum compressive strength is the pressure from which a (normally standardised) specimen deforms irreversibly. The breaking load is set in relation to the cross-sectional area. Transferred to a plain bearing, this would be the wall – i.e. the cross-sectional area between inner and outer diameter.

Unfortunately, it doesn’t make much sense to measure the compressive strength on test specimens. This would also hardly be possible otherwise, as the compressive strength would then have to be determined individually for each individual component. Another factor is the general shape of the component. Plain bearings are cylindrical bodies on which pressure is often applied from only one direction. This means that the whole surface does not have to absorb the same pressure. How does this then relate to the compressive strength? So, it’s not that easy. In addition – to stay with the example of the bearing position – not only the “simple” pressure has to be absorbed by the plain bearing. The load is not permanently and evenly distributed over the bearing surface but acts impulsively or abruptly or occurs as edge load at one or more points. That’ s also difficult.

And now what is surface pressure?

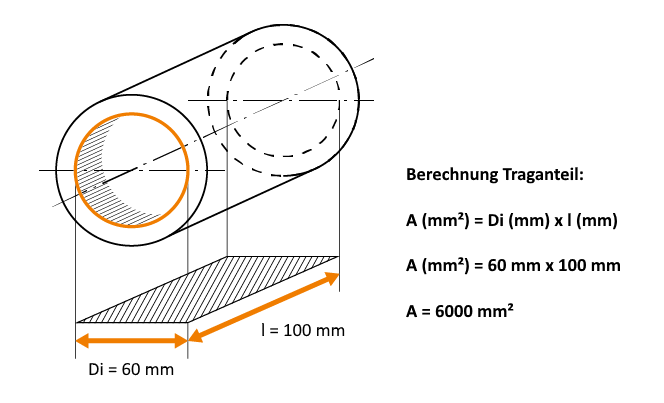

The surface pressure is also a pressure. In other words, a force that acts on a certain area. However, this is a different surface area than for compressive strength. It is the surface of the body. In this respect, the terms compressive strength and surface pressure are perhaps simply chosen somewhat unintuitively. Let us note: the surface pressure actually means the surface area pressure. In relation to our plain bearing the surface pressure means the pressure prevailing at the contact surface between hole and plain bearing or plain bearing inner surface and bearing pin. In this respect one could also speak of contactsurface pressure. This surface pressure also considers the shape and load characteristics of the plain bearing somewhat better.

And here lies the main difference between compressive strength and surface pressure. While the compressive strength refers to the component cross-section and the stresses IN THE material itself, the surface pressure describes the stress at the contact surface.

Another big difference: the measuring method. The measurement of compressive strength is largely standardised and is often carried out using uniform and exemplary test specimens. The maximum – or usually “maximum recommended” surface pressure is often based on empirical values and a number of different tests carried out for the respective component series. These values are accordingly often different.

Surface pressure and compressive strength – what is more important?

The question of whether surface pressure and compressive strength are equally or differently important cannot be generally answered unambiguously. If in doubt, consider both. For component specific questions, however, the surface pressure often provides the more practical findings.

We would be happy to assist you!

We would be pleased to support you in the design, dimensioning and calculation of your bearing positions and supply both custom-made special solutions and standard components from our extensive plain bearing catalogue – all from one source and with no minimum order quantity.

J.W. Fijnvandraat BEng

This explanation only refers to (max) surface pressure and compressive strength.

But in your mechanical properties I find for e.g. material J, a Pressure load of 8700 psi and a max recommended surface pressure of 5076 psi.

Which value do I use for evaluation of the maximum load (not pressure!) that I can apply on the bearing?

Yssa

what is the maximum surface pressure for aluminum