Safe control device guide on indoor crane

Jens Göbel | 14. April 2020

In order to control the hoist on the indoor crane, a manual control unit, also known as a control device, is required. This is usually connected directly to the hoist on the crane girder via a control cable. In doing so, it can be moved along the crane girder independently of the hoist. This is to prevent people from standing below or in direct proximity to the lifted load when operating the indoor crane.

Cable trolley system (festooning) for control device:

In the past, the control cable of the control device was guided by means of cable trolleys running along the crane girder on an appropriate profile. With this cable arrangement the control cable hangs down in loops. As with any cable trolley system, this type of cable guidance also has some disadvantages. Loads that are picked up and transported can become entangled in the hanging cable loops. Also the maintenance effort and the associated downtime of the indoor crane should also not be underestimated.

Remote control for indoor crane:

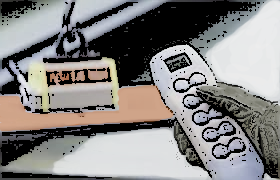

A modern alternative to the control device directly connected to the hoist is the remote control. It enables the crane and hoist to be operated from a larger radius of movement. Current models have all safety-relevant functions, such as the emergency stop switch. In addition, this technology is also becoming increasingly attractive in terms of price.

guidefast control for control device guidance:

If a direct connection of the control device to the hoist is necessary, there is also a suitable energy chain solution for this. The guidefast control system is installed directly on the crane girder. The cable for the control device is led past the hoist via a moving end arm. This ensures that the manual control can be moved along the entire crane girder, independent of the hoist. The energy chain ensures that the cable is guided safely. The trough system has been designed in such a way that the moving end arm remains secure in the trough even if it is subjected to high tensile strains in the short term.

The guidefast control is especially interesting for applications that are used in the ATEX area. A special, electrically conductive energy chain material (ESD material) is used for such applications. The guide trough system is also earthed accordingly via the crane girder.

More about compact cable guidance for the hoist can be found in the blog post: How a compact cable guidance system on an indoor crane looks

On our website, you will find further examples and solutions for cable guidance on indoor cranes. You will also find our brochure for free download.

Do you still have questions or an application you would like to discuss with us? Arrange a virtual consultation appointment now