Reliable energy supply for extruders and extrusion systems

Christian Schäfer | 28. April 2020

Extrusion is one of the primary plastic technology processing methods. The products created can be found in many areas of application, including packaging, automotive and construction industries. Products that are created by extrusion include bar stock such as pipes and rods, profiles such as window frames and seals, filaments, hoses, film, cable jackets and car tyre running surfaces.

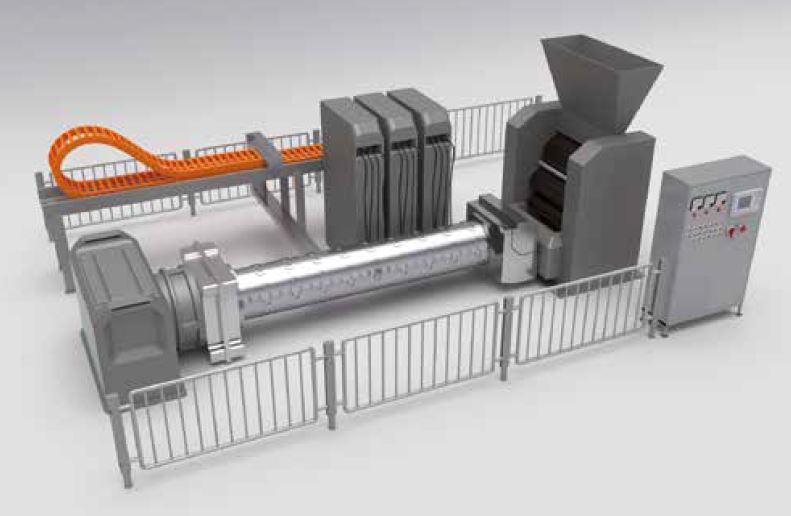

Besides producing extruded bar stock, extruders serve as a preliminary stage in the injection moulding process. In this blog, we will focus on energy supply on extrusion lines (the combination of extruders and downstream machines).

Precise circular movements on extruder measuring systems

When film is blown, it is monitored continuously and precisely to the millimetre for uniform width and thickness. This is achieved with contactless measuring devices. Pre-assembled igus energy chains are used in this process in the blown film extrusion measurement and control system.

Before igus E2/mini e-chains are used, all components necessary for energy supply are assembled. The readychain solution saves time and weight and reduces cost (HCH. Kündig & CIE AG, Rüti, Switzerland)

Ensure long service life even at high speeds

Machining and downstream units are used in extrusion. Among the latter are vulcanising equipment, winding machines and cutting machines. igus products give you an advantage here as well. In such high-speed equipment as cutting machines, long service life of e-chain systems and chainflex cables from igus ensure reliability.

Lubrication-free and dust-proof properties

Extruders are often used in very dusty environments, such as tyre production. Lubrication-free and dust-proof properties have top priority in such operations. Maintenance-free and tribologically optimised polymers from igus fulfil these and many other requirements. igus products are completely lubrication-free and exhibit great strength even at high speeds.

You can discover how igus products extend your extrusion line’s service life, preventing production downtime, here.

Further fascinating blogs from igus polymer machines experts can be found here.