Mount energy chain systems of up to 100 metres with little effort

Beke Nieszytka | 18. August 2020

Energy chain systems play an essential role for many types of machines and plants and this within the most diverse industries.

This is now firmly anchored in the minds of plant designers, fitters and maintenance personnel. Energy supply systems are used in various forms and types – in hanging, lying, gliding form, in indoor and outdoor applications, in various lengths and equipped with all kinds of cables and hoses.

We at igus® have already equipped many applications within and outside Germany, in various industries with energy chain systems – individually adapted to the system and the customer’s wishes.

But how do energy supply systems actually arrive at the plant?

And how are energy supply systems for long travels actually installed?

Imagine an energy supply system with a length of 80 metres. How can such a chain be transported fully functional, undamaged and – considering the weight involved – easily and safely to the plant and assembled there with little effort?

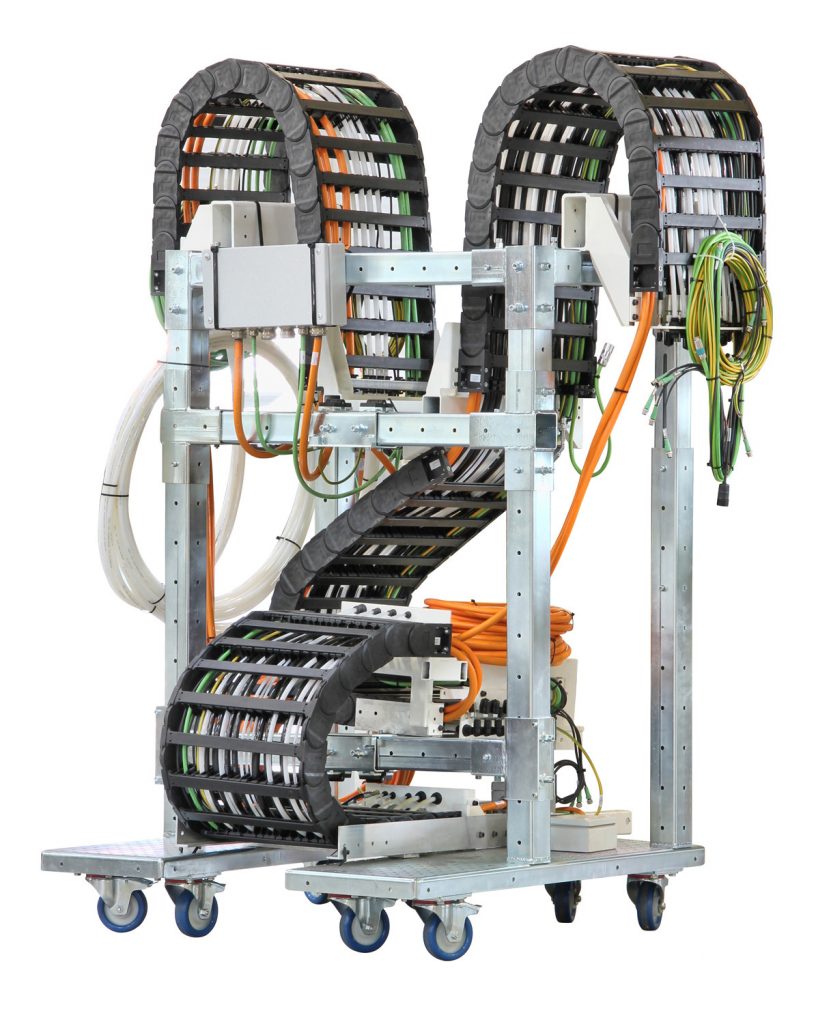

The readychain® rolling rack for fast assembly on long travels

With the readychain® rolling rack, energy chain systems with a travel of up to 100 metres can be easily unrolled with little effort and a lot of comfort – for example in gantry machine tools or crane systems.

igus manufactures reliable, tested energy chains and cables for use in chains as well as fully harnessed systems known as readychain® systems. Especially for long travels, complete systems not only save time in assembly, but primarily offer predictable reliability as well. Customers can rest assured that they are getting a system in which all components are matched to one another for movement.

The rolling rack makes transport and assembly of the readychain® systems for long travels even easier. For this, the ready-to-install harnessed chain is rolled up on a drum, which is then mounted on a steel rack. The rolling rack can be easily moved by a forklift to the desired location, and can be unreeled there by just one person. In addition, the rolling rack is reusable and as a system is individually adaptable to chain type and reel size.

You can see here in the video how the readychain® rolling rack works:

Expansion of the transport system series:

The transport rack for safe and quick assembly of energy chain systems

If modifications to the machine become necessary, such as attachment of subsequent components, these can be performed at any time due to the modular design of the rack. The process costs in the prototype phase can be reduced by up to 80 per cent, and up to 50 per cent over the entire assembly process.

Where the application has space constraints, the use of a readychain® rack light offers an edge length of just 40 millimetres. The light transport rack is so slim that the energy supply system can be used in even small applications, precisely fitting to the machine. The readychain® rack is also available as an intelligent readychain® rack with rotating traversing units and can be electrically or mechanically positioned on the machine interface.

Learn more about the readychain® rack here

Your advantages with the readychain® rack

1. Everything from one source

- Pre-assembled, customised energy chain systems

- From design up to maintenance:

- -30% procurement costs

2. Flexible components

- Telescopic supports/braces

- Easy modifications during high-volume production thanks to modular principle

- -80% construction time

3. Sustainable use

- Modular construction kit: no disposal after end of production run

- Fully galvanised components for extended service life

- -50% packaging costs

4. Precisely fitting plug & play

- Intelligent interfaces for quick and easy installation

- Interface plates, linear bearings sensor-actuator boxes, link with central lubrication

- -50% installation time

5. Easy transport

- High strength transport units

- Lowest handling costs even without the use of forklift or crane

- -20% logistics cost

6. igus® project management

- Upon request from our readychain® project managers at your premises

- Single contact person from prototype to high-volume production

- You can decide what you save