Maximum service life from the roller: condition monitoring in container cranes with intelligent rol e-chains

Richard Habering | 16. June 2021

More than 25,000 igus energy chains travel long distances every year in STS cranes, storage and retrieval units and linear robots. In all these areas of application, customers around the world rely on the tough, modular igus energy chain systems. To load and unload the cutting-edge Triple E-class container ships, larger STS cranes must be built or existing cranes retrofitted. Container crane availability and dependability requirements are also increasing. This affects the design and selection of energy supply systems. For future operations, in addition to using rol e-chains, there is much to recommend self-monitoring systems fitted with sensors. They ensure the greatest possible availability for the energy supply – and for the crane.

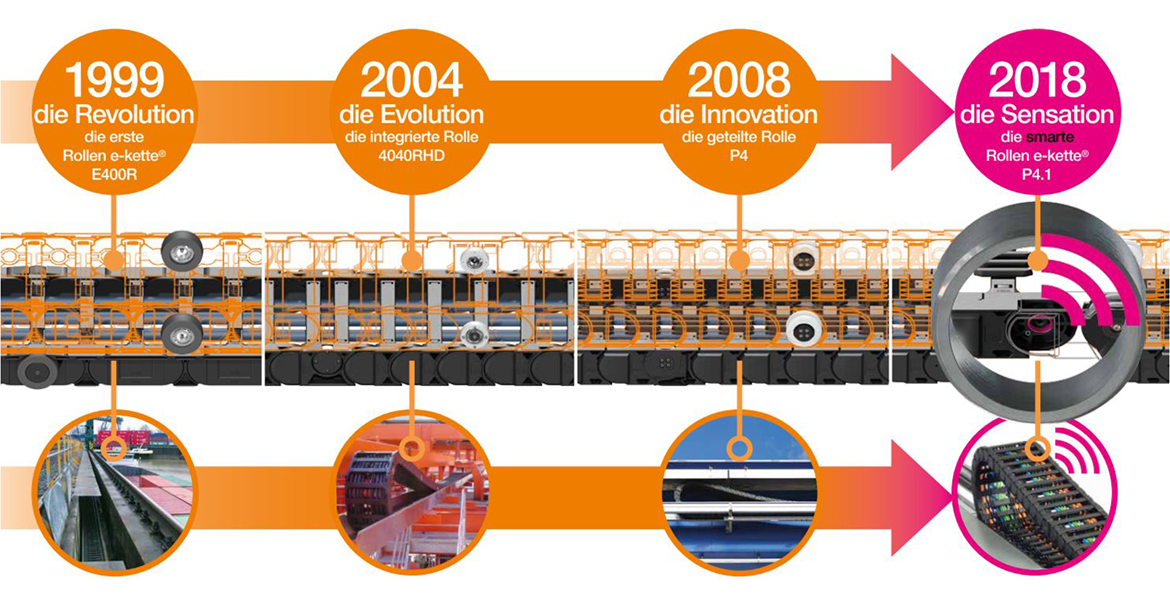

From technical innovation to standard product – the development of rol e-chains®

Given the stringent requirements and high speeds on container cranes, such rol e-chains, or chains with integrated rollers that roll in guide troughs, are used there. igus has had energy chain links with rollers in its product range for more than 20 years. They reduce the pull/push forces on long travels and ensure a significantly longer energy supply system service life. Because the energy chain rolls and does not slide, it runs quietly and with little vibration. Wear is significantly lower than for designs without rollers, and the power needed for movement is also as much as 57% lower.

In the latest development stage, maintenance-free tribo-polymer plain bearings considerably lengthen service life. The new P4HD can be fitted with smart sensors to monitor items such as B. wear, push-pull movements and irregularities. They can be used to trigger alarms or maintenance recommendations, which are communicated with a radio module. In order to prevent a crash, the associated drive can be shut down automatically when it exceeds a prescribed power level. The sensor for continuous condition monitoring is integrated into a standard side section of the chain, but this does not restrict the usable inner width in any way.

Continuous condition monitoring for container cranes is just the beginning

This solution’s performance is even greater, as the video below demonstrates: the i.Cee module is used to compare energy chain condition data with experience from current applications and refine them. On this basis, the user can plan maintenance predictively and based on the actual energy chain state. The service life prediction largely corresponds to reality – that is, to the state of the individual energy chain. There is another advantage: maintenance personnel can access energy chain service life data at any time, regardless of location. This greatly reduces the likelihood of unplanned downtime. igus believes that this technology will become a part of the future container crane energy chain application.