How can vibrations in energy chains be minimised?

In order for machines to operate with low vibration and thus reliably and precisely, designers in energy chains must master the so-called polygon effect . If the chain does not run completely round in the bending segment, a circle, which is the ideal movement for the chain, becomes a polygon. During the unwinding of the chain links there are vibrations in the longitudinal and transverse directions. It creates vibrations. In order to minimise these vibrations, igus therefore uses small parts as the design principle for e-chains with pin/bore connection.

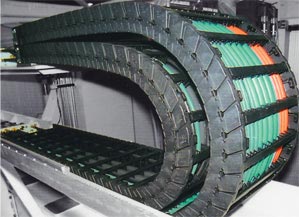

For maximum vibration reduction, igus has also designed an alternative connection component for chain links: an elastic spring element made of high-performance plastic. Thanks to its geometry, the polygon effect during unrolling is reduced to a minimum. The spring elements are used in the energy chain series E3, E6 and E6.1. Users achieve the lowest vibration results in combination with a linear motor whose drive is also designed for low vibration.