How polymer spherical bearings ensure more efficient energy generation

igu-blog-adm | 30. November 2020

Everyone has seen them at some point. Individual solar modules on a house roof or many of them arranged to create a solar power plant. These solar modules are generally fixed in place, oriented optimally to catch the sun.

In large solar power plants, energy is generated more efficiently with special tracking systems, the “solar trackers”. These systems allow vertical solar module rotation of +/-60°, achieving the optimum sunlight angle for longer periods.

Such photovoltaic systems are usually set up in very dry, remote areas. Various adverse factors such as dirt, dust, UV radiation and wind load can present great challenges for the solar module and its substructure.

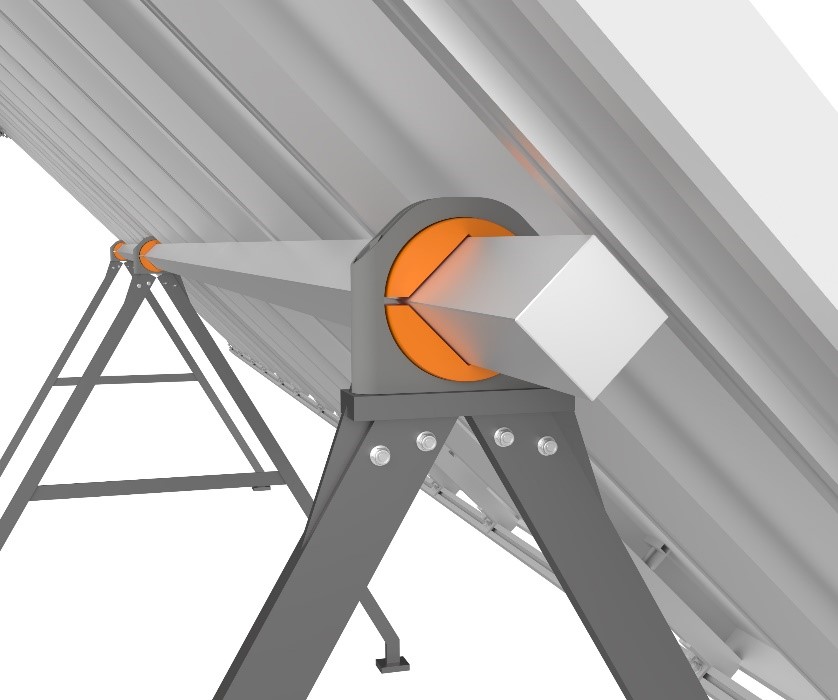

The structure of a tracking system always includes a long steel shaft of a wide variety of shapes and dimensions (round, square, hexagonal) installed across multiple solar modules, stringing them together. The individual strings are driven by a motor and rotated throughout the day. Since strings can be very long, intermediate columns are installed at regular intervals to provide additional support.

Each of these columns is equipped with a polymer spherical bearing that both supports the string and allows it to rotate. igubal® pillow block bearings and iglidur® half-shells of various dimensions are already in use in large photovoltaic plants. They use special igus® high-performance polymers, such as igumid® G and iglidur® J4, which are resistant to environmental conditions, such as temperature cycles, UV radiation and high structural system loads. Spherical pillow block bearings can also compensate for minor misalignment or foundation unevenness.

The lubrication-free operation means resistance to dirt and dust, especially important in desert-like areas and reduced wear – another advantage of these materials. No regular maintenance is necessary, so maintenance downtime is eliminated. This pleases the plant operators, their investors – and, of course, us.

We would be happy to present further advantages and possible applications of our tribologically optimised polymer plain and spherical bearings.

Feel free to contact me:

Richard Won

Phone: +49(0)2203-9649-7076

E-mail: rwon@igus.net Internet: https://www.igus.eu/info/renewable-energy