How do you combine your favourite motor with igus linear axes?

Adriana Glazer | 10. July 2020

Have you have always asked yourself: “How do I attach our motor to an igus linear axis?” No? We’ll answer it anyway.

igus is a manufacturer of linear axes. The mechanical transmission of the drive forces is carried out by a toothed belt or a lead screw in combination with our tribologically optimised high-performance polymers. The drive forces can be generated by muscle power and a hand wheel, or electrically in combination with a motor. We would now like to take a closer look at the latter, since igus can now boast a diverse portfolio of motors, but special requirements are regularly made that we cannot meet on an ad hoc basis. In order to still be able to support prototype construction and small batch production, we offer prefabricated motor flanges that match your motors.

How is a motor flange constructed?

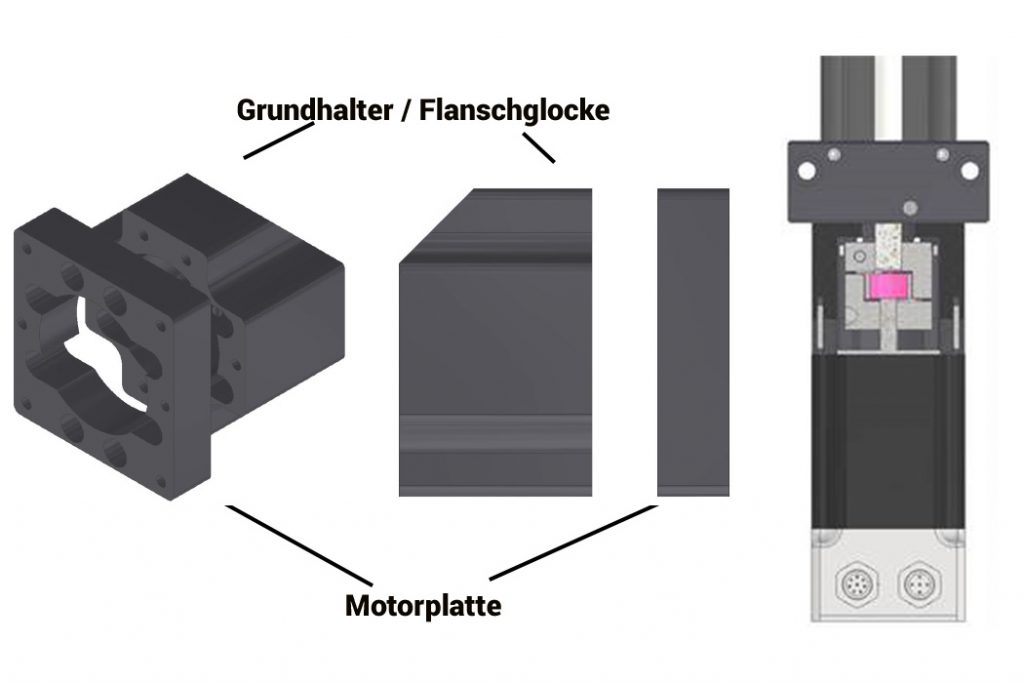

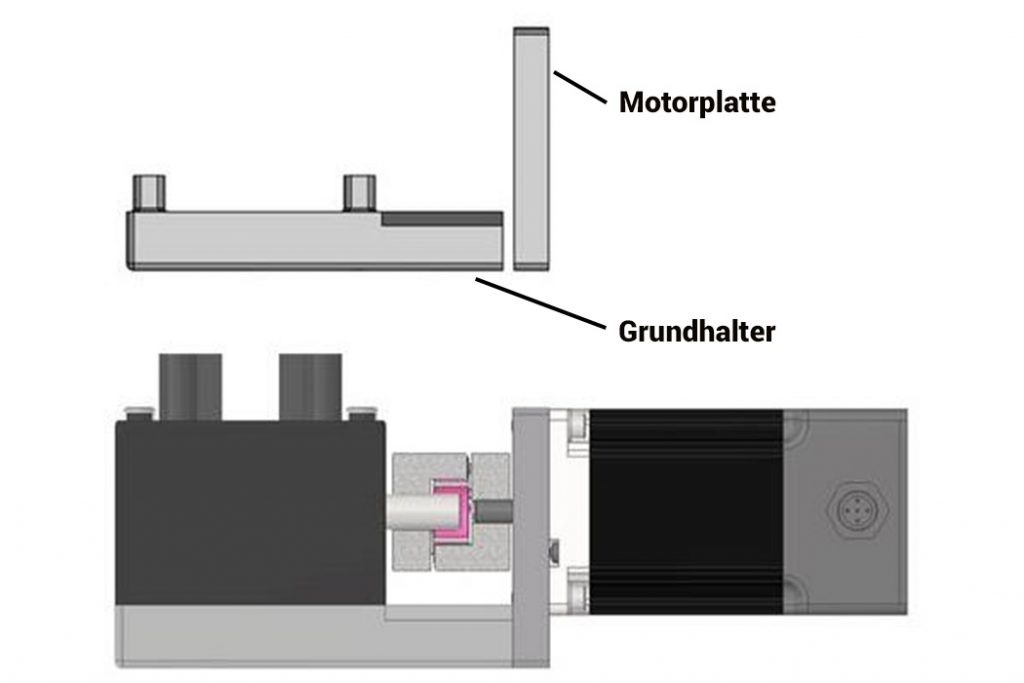

Our motor flanges are always constructed in two parts. These include the basic holder, which ensures stability and correct alignment, and the motor plate, which ensures the correct screw-on dimensions.

Motor flange with lead screw axis as basic holder

Here, the basic holder consists of a flanged bell in which the coupling for the mechanical connection of lead screw and motor shaft disappears. For a customer-specific motor flange, the basic holder (the flange bell) remains the same here. Only the motor plate is adjusted.

Motor flange with toothed belt axis as basic holder

In principle, the motor flange of the toothed belt axis has the same design. Here, the basic holder grips right into the axis and bends the motor by 90° to the axis direction. In this way, we ensure that the motor shaft and the axis drive shaft are opposite each other. The basic holder is available in different lengths, so that even longer motors can be flange-mounted. The motor plate also provides the appropriate screw-on dimensions here and is adapted to the customer-specific motors.

When connecting motor with linear axes, what technical data is important?

In the best case you send us the original data sheet of the motor and the exact designation or part number of the required motor. The data sheet should contain at least the following information

- Mounting hole circle diameter and mounting thread

- Centring diameter and height

- Distance over hubs

- Length of the motor shaft

- Diameter of the motor shaft

What does it cost?

Usually we manage to get a price of €50 – €150 for one unit. In individual cases these prices may vary. For larger quantities >100 the price will hardly differ noticeably or not at all from the standard price of the axis.

If you have any further questions or just want to check if your motor would match, please feel free to contact me or my colleagues. We would be happy to look at your individual needs and requirements. We would be happy to help.

Do you have any questions?

Send us your contact request here

Our experts will help find a solution for you.