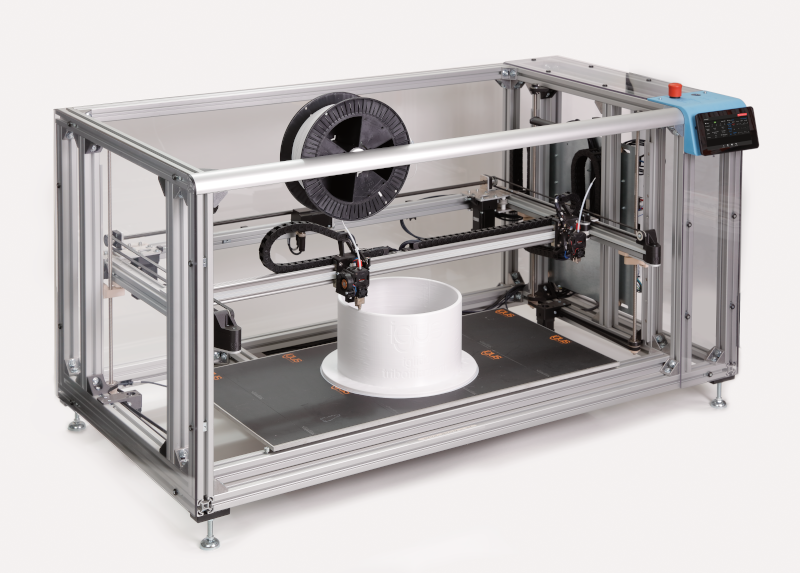

Free design data: DIY large-format 3D printer

Aranca Ehret | 15. November 2022

Can you 3D print components as large as one metre yourself? That is something special even today. Desktop printers with component sizes of up to 300mm have become almost commonplace. There is a wide variety of devices and manufacturers. Depending on the manufacturer and whether you buy a construction kit or an already assembled printer, the acquisition costs usually range between €500 and €10,000. However, the choice of affordable 3D printers with a maximum part length of 1,000mm and more is still very limited. Here, the costs are usually €40,000 and more.

In the process, customers have already proven several times that the igus® modular system is also very well suited for the construction of large-format 3D printers. For example, drylin® multi-axis linear robots were used in a large-format 3D printer for house facades.

The 3D printing team at igus® also took advantage of this and built their own large-format printer for the igus® 3D printing service.

What were the biggest challenges in building and commissioning the large-format 3D printer?

First of all, when designing such a 3D printer, it is important to choose a stiff construction, as the larger dimensions mean that the deflection and vibrations of the printer very much limit its function. In addition, especially with a heated print bed, it is important to compensate for the enormous thermal expansion (e.g. with an aluminium print bed of 1 metre length, a thermal expansion of more than 1mm is reached at a temperature difference of 50°C). This problem is solved, for example, by float-mounting the print bed, allowing it to expand without deforming the printer. Furthermore, the print bed is scanned before printing to compensate for unevenness via the software.

During the actual 3D printing of the components, the dimensional change due to temperature differences (shrinkage) of the plastic component is also the biggest challenge. If shrinkage is too high, either the component will not be dimensionally accurate or the component will detach from the print bed. In the same way as in regular filament 3D printing, the following measures can be taken to counteract this:

Firstly, a material with very low shrinkage should be used. In the following, the shrinkage was calculated as an example for a plastic part with a length of one metre made of three different common materials:

ABS: 5mm

PETG: 3mm

PLA: 1mm

Secondly, it makes sense to reduce the temperature difference, e. g. by using a heated installation space. This means that part of the shrinkage does not take place until the component has finished printing and the component cools down together with the printer. No active heating is used in the printer built here, as this brings its own challenges with such a size. However, due to the enclosure and the heated print bed, there is passive heating of the air, which also helps here.

Which components were installed?

The following igus® components were used in the construction of the large-format 3D printer:

- X-Y axes: Independent Dual Extruder (IDEX) with drylin® W and N profiles

- drylin® R hollow profile shaft for transmitting drive torques to the belt drives

- drylin® N and trapezoidal lead screw drives for the Z axis

- E2i.15 energy chains to connect the X-Y linear robot

- drylin® E Nema 17 motors for the Z axis

- drylin® E Nema 23 motors for X and Y axes – chainflex® CF9, CF298 and CF299 cables for all electronic connections

- xirodur® B180 xiros® deep groove ball bearing in the filament spool holder for improved unrolling of filament spool

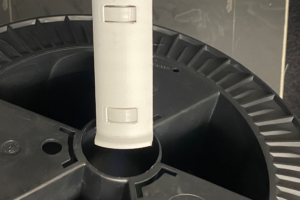

In addition, the in-house 3D printing service was also used to produce, for example, structural components, holders, belt clamps and special mounting brackets for the installed energy chains. Among other things, the new igus® filament igumid® P190 was used. This is a carbon fibre reinforced filament with an incredible flexural strength of up to 237MPa and an enormous modulus of elasticity of 11,500MPa. In addition, the special drive nuts were made of iglidur® i3 by laser sintering. Individual 3D printed components can be requested and ordered very easily in the igus® 3D printing service. All that is required is to upload the STEP model to www.igus.eu/idd. Then just select the right material and quantity and order directly or request a quote.

Download design data free of charge

You can download the design data free of charge at the link below. Note that the printer is specifically designed as a DIY 3D printer. igus® is not a manufacturer of 3D printers and will therefore not be able to offer support in setting up the 3D printer.

Key data of the DIY large-format printer:

- Installation space dimensions: approx. 1000 x 500 x 500mm

- Outer dimensions: approx. 1612 x 816 x 800mm

- Weight: approx. 40-60kg

- Control system: Duet3D system with touchscreen interface

- Print head: two independent print heads, Direct Drive, model and nozzle diameter freely selectable

- Printing table: 10mm cast aluminium plate

- Just setup time: approx. 3-5 days (when all components are ready and plus any research)

What did we learn from the setup?

Keep It Simple – Even though there are lots of nice options, e. g., to integrate as many functions as possible into a component or to design solutions that are as elegant as possible, the simpler way is often the more effective one.

Attention advertising: drylin® is a great modular system!

Energy chains are an important part of a machine as soon as components or assemblies move in relation to each other – no matter to what extent – and should be included in the design at an early stage. Above a certain filament 3D printer size, it also makes sense to think about granulate instead of filament as the starting material. Since the printer presented here has a modular design, it should also be possible to equip it with a granulate extruder.

More information about 3D printer construction is available here:

Lightweight, cost-effective, and lubrication-free products for 3D printer construction kits