Edge load in practice – why recommended surface pressure is often misleading

Lars Butenschön | 24. March 2020

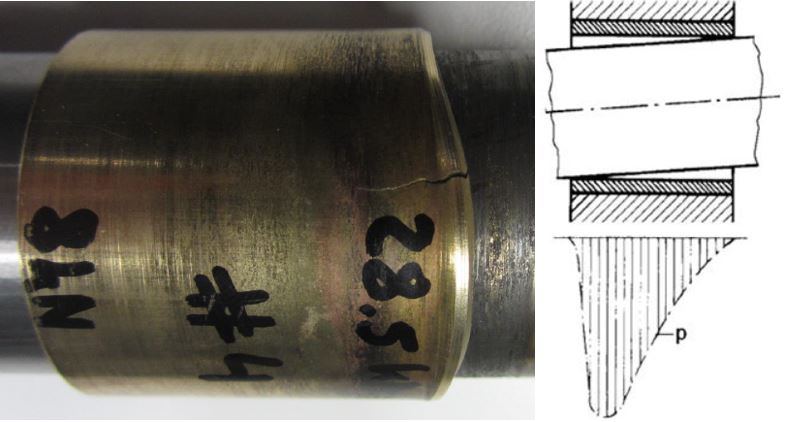

It is not infrequent that plain bearings in various applications abruptly transform into piles of debris. There is the dumper whose bearings give up the ghost with a dramatic crunch and the doors that first squeak and then settle. And when that happens, users, sales consultants, and designers stand there and wonder what made it happen. “Lubrication?” – We don’t need any. The manufacturer says it’s lubrication-free.” “Corrosion?” “No, there’s no metallic dust.” “Was it made of the right material?” “Sure. Here’s the data sheet. Pv value, temperature, surface pressure – it’s all where it should be. With a safety margin.” So is everything OK? Might there be a material fault? Wrong tolerances? A frequent issue is edge load. But what is edge load? And why does it often remain undiscovered until it’s too late?

An example of edge load

A bearing point that you are guaranteed to have passed a thousand times: door hinges. The Belgian manufacturer Anyway Doors has a special system that takes a new approach to door hinge design. The door hinges are installed in the floor and lintel, allowing a design that is something like a revolving door. In both, plain bearings with a load-bearing flange are used. So, the bearing performs two functions at once. It facilitates the pin’s rotating movement while supporting the door at the same time. A plain bearing the size of a one-cent piece supports the door, which can weight up to 150 kg. Across the load-bearing surface, this results in a surface pressure of just under 20 MPa. For comparison, a small car weighing two tonnes on an index finger would be 30 MPa. A wide variety of bearing materials are suited to this load scenario. But iglidur Q290, a material specially developed for heavy loads, is used here. Why?

150 kilogrammes of load on the area of a penny

The term “surface pressure” refers to force per unit of support surface. For plain bearings, the assumption is normally that a bearing’s cross section (inner diameter x bearing length) is the same as the support surface. The load to be supported is distributed across this surface. This assumption causes problems when the support portion – the bearing surface that is to support the load – is smaller. In the present case, however, lever forces are exerted on the plain bearings. Since the door’s bearings are not positioned centrally, the door’s weight is not distributed evenly across the bearing. The lever effect means that the door exerts more force on one side of the bearing than on the other. An edge load arises at the edge of the flange, causing damage to the bearing. This does not happen here. The plain bearings have no trouble handling the loads. Tests have shown that even after more than 150,000 cycles, no wear is discernible.

How to avoid bearing damage resulting from edge loads

It is often enough to choose a bearing material that is better suited. For plain bearings made of plastic, fibre-reinforced materials can help bear the loads. Plain bearings made of woven filament are especially resistant.

Enlarging a plain bearing by such means as using a longer bushing can also help.

But it is best to avoid edge load where possible. If you can, add bearing points to your design or improve the alignment of shaft and bearings in order to prevent moving parts from tilting.

We would be happy to advise you.

Edge loads and load distribution in plain bearings in general can quickly become very complex, so the topic is too extensive to cover in a single blog post. We would happy to advise you personally on these and other questions and help you find the most cost-effective plain bearing that will work for you.