Breakage detection in energy chains with smart plastics EC.B

Richard Habering | 6. January 2021

What is breakage detection (EC.B)?

EC.B breakage detection in energy chains is a condition monitoring system. Installing this system allows extremely fast detection of breakage in any link in the e-chain®. This immediate detection of breakage in the energy chain can prevent expensive damage while increasing equipment reliability.

Components of an EC.B system?

The system is made up essentially of just five easy-to-install parts (if the separator is counted as a part). At the moment, the EC.B system can be used with all E4.1 and P4.1 sizes.

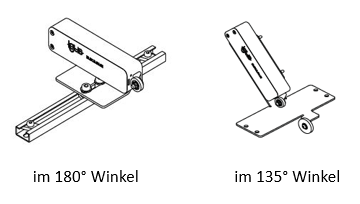

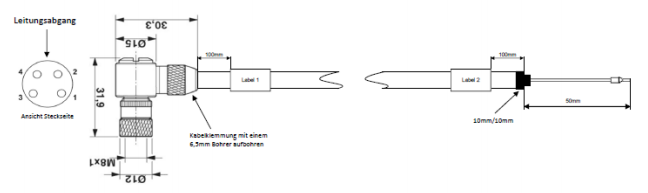

Sensor unit at a 135° angle or at 180° (flat):

Non-stretchable rope

Separators to which the rope is secured

EC.B module

Linking cable between the EC.B module and the sensor unit

How does breakage detection (EC.B) work?

First, use the installation instructions to install all components, then use the EC.B module to connect the system to the machine. The system is now ready for operation, and works as follows:

In normal operation, the e-chain detects no measurable changes in the length of the rope installed, since the rope is located in the neutral phase of the e-chain®. If a link were to break somewhere in the energy chain, the sensor unit would pick up movement in the rope. As soon as the sensor unit mounted on the moving end detects this tension in the rope, it passes that information on to the EC.B module. Depending on its settings, the EC.B. module switches the system off or sends an optical signal (red lamp) to the system’s control unit.

Richard Habering can explain the system’s functionality much better, and he uses visual aids.

The following animation shows the function and construction of the EC.B breakage detection system.

Why & where is breakage detection (EC.B) used?

- Detecting damage early prevents even more damage and the associated expenses

- Quick detection allows quick maintenance

- No production downtime

- Replaces visual inspections for breakage in the energy supply system (which is difficult and sometimes impossible in any case)

The typical areas of use for EC.B breakage detection are gliding applications, also called long travels. These applications make it especially unlikely that the entirety of the energy chain will be accessible for visual inspection. This makes it difficult to detect breakage in individual chain links, so they are rarely detected or not at all. If they are detected, it is usually too late.

High stress due to heat

Heavy soiling or inaccessible