5 extreme applications for polymer plain bearings

Lars Butenschön | 27. March 2020

Those who know plastic will take metal! You still hear this sentence often enough from designers and maintenance personnel. It is felt that the number of those who use or even prefer plain bearings made of plastic is increasing. Whether you are a plastic bearing sceptic or enthusiast (or neither), these application examples of plastic bearings could still amaze you.

Rank 5: Dust, scorching heat and UV radiation in solar systems

Would you constantly expose a plastic bearing to the sun and high UV radiation? In fact, special materials are used for the bearing which are UV resistant. Solar panels work more efficiently if their inclination is continuously adapted to the position of the sun in the sky. This “sun tracking” is mounted in a correspondingly mobile manner and must function daily in continuous operation. Especially in hot and remote regions, people and materials are exposed to the most adverse environmental influences. These range from large temperature differences to rain, wind and harmful UV radiation. This destroys the polymer chains in the plastic and thus weakens the resilience of the material in the long run. The result: Blocked tracking systems and sagging mirrors. The solution: Plain bearings made of UV-resistant iglidur® JUV plastics. Find out more here.

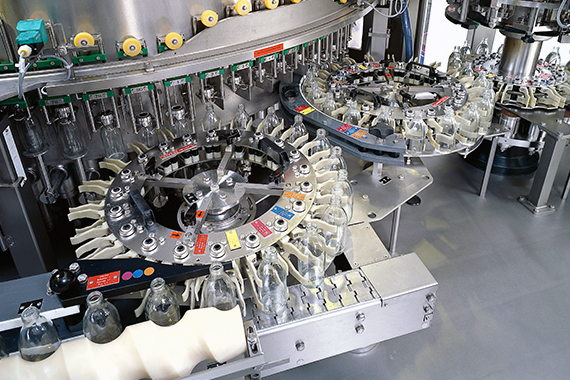

Rank 4: Corrosive cleaning chemicals and food

In a modern bottling plant, more than 60,000 bottles are filled in a single hour with a wide variety of beverages. The machine components must not only be suitable for contact with food and meet the strictest requirements of various authorities (FDA, EU 10/2011), but must also be temperature-resistant and above all insensitive to aggressive cleaning agents. Hundreds of plain bearings are used in the complex mechanisms of the filling valves and ensure the longest possible interruption-free operation.Find out more here.

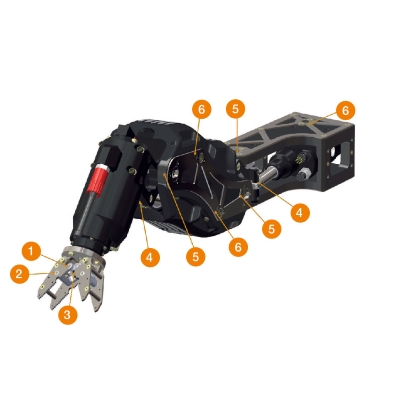

Rank 3: In the depths of the ocean

Applications under water pose great challenges for the technology. Especially in the deep sea, where failures can hardly be rectified and the most difficult conditions prevail. High pressure and salt water significantly limit the choice of materials and components. Under these conditions, plain bearings made of iglidur® materials are used in robot arms and automatic maintenance devices, as well as in valves and flaps. The plain bearings need neither lubrication nor protection against corrosion and also exhibit excellent expansion behaviour. Find out more here

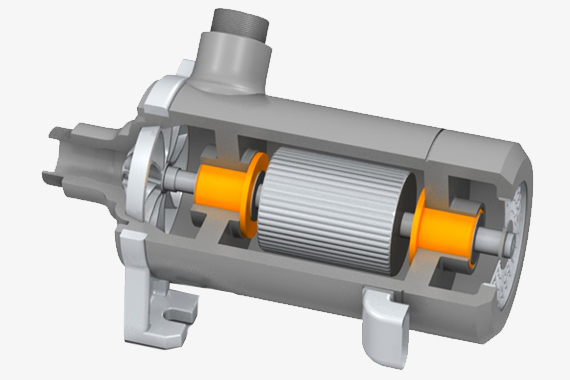

Rank 2: High speed in motor vehicles

Did you actually know that on average over 20 iglidur® plain bearings are installed in every vehicle produced in Europe? From seat adjustment to the accelerator pedal, a wide variety of polymer bearings are used here. Many of these applications have highly complex requirements. Every gram and every penny saved counts. At the same time, tolerances and gap dimensions have to be precisely maintained. Then the haptics must meet the highest standards. In addition, the operation should be completely quiet … and then of course there are high loads, cathodic dip painting processes or high temperatures to cope with. Special demands were also made on iglidur® bearings used in coolant pumps. Their performance requirements continue to rise, especially for electric cars, as they have to cool the electric motors and batteries during operation. Speeds in excess of 2 metres per second, at temperatures above 150°C, put polymer plain bearings to a hard test. Find out more here.

Rank 1: Over hill and dale in the cultivator

Cultivators are machines for tilling the soil in agriculture. They are used to loosen and break up the soil in the field to prepare it for sowing. Sometimes it goes even at 10km/h over a field with 10cm ground frost. But the real problem are stones. If the cultivator tines collide with larger hidden stones, these elements made of solid steel can bend or even break off. To prevent this from happening, cultivators have overload protection. The tines are spring-mounted and can spring back and return to their original position when they hit obstacles. The extreme impact and edge loads that occur in this environment secure this application the first position in this ranking. Find out more here.

Test your own application now

These were only 5 examples from a huge variety of different applications. These range from bicycle pedals in mountain bikes, to bearings in hydraulic cylinders, to tiny bearings in magnetic valves. More than 200,000 customers from the most diverse industries worldwide already rely on plain bearings made of iglidur® polymers. In order to be able to make precise statements about whether the plain bearings meet the requirements in your application, igus® provides a free calculation tool. With just a few clicks you can check which iglidur® bearing will last how long in your application. Try it for yourself!