Where are cables used?

Cables for cleanrooms

Nils Jäger | 30. July 2021

We have already shown examples of areas of application for our cables in previous articles. The industries and applications are multifaceted. One possible area of application is cleanrooms. The special requirements of cables in cleanrooms and our special chainflex solution is our topic for today.

What is a cleanroom?

Cleanrooms are rooms with an extremely low concentration of airborne particles – substances and particles in the air, some of which we cannot see with the naked eye. These cleanrooms are necessary wherever such particles in the air would impair work. Cleanrooms are found in the pharmaceutical industry, for instance, but production facilities in the electronics industry also often require cleanrooms or ultra-cleanrooms. Standards lay out the rules that apply here for the degree of cleanliness. Vaccines are perhaps the most obvious current example. Nobody wants to be injected with an impure substance. That is why utmost care must be taken to keep everything absolutely clean during the manufacturing process. In semiconductor manufacture, dust particles impair quality and processor function.

But it is not just the room itself that must be clean. The machines involved must operate in such a way that they emit no particles. In this case, this means that energy chains and cables installed must operate with as little abrasion as possible. The fewer impurities there are in the air, the less important additional air cleaning becomes.

What cables should be used for cleanrooms?

In general, many cables can be used for cleanrooms. What is important is that they generate as little abrasion in the energy chain as possible. This is why some jacket materials are better than others. For example, both PVC cables and cables with TPE outer jackets can fulfil the requirements of ISO Class 1 for cleanrooms. If you check both cables in direct comparison, cables with a TPE outer jacket have slightly better abrasion behaviour. But it is not only cables that affect impurity levels, but also energy chain installation and filling. The e-chain materials can affect abrasion behaviour.

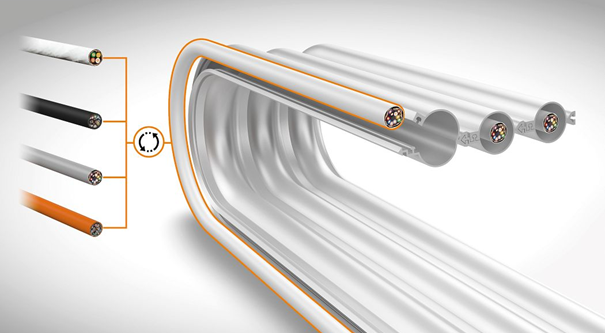

There are also very sensitive areas in which conventional energy supply is undesirable. Here, completely closed systems such as our e-skin® flat are used. We have developed a special cable series for just this type of energy supply system: the chainflex® CFCLEAN.

Our new CFCLEAN cable range, specifically for cleanrooms

The requirements of cables for cleanrooms are specific. We developed our CFCLEAN range to be harmonised perfectly with cleanroom requirements. Instead of an outer jacket, these cables have PTFE banding. This prevents abrasion to a very great degree, since PTFE has very good sliding properties and reduces the outer diameter. But what is special about this design is that the cables can be used only in so-called pods, since the PTFE film does not provide suitable mechanical protection. Here, the igus® e-skin® flat is ideal as well as very flexible thanks to its modular design. Another advantage of the system is that it is completely closed, including the mounting brackets, so any particles remain in the pods.

Series production and product launch in April 2021

From the very beginning, long service life was important to us, since machines in the semiconductor industry go through a very large number of cycles, and maintenance time is very expensive. That is why the CFCLEAN prototypes and the e-skin® flat are tested to many millions of cycles in our 3,800m² test laboratory. Even though the CFCLEAN was introduced long ago, cable tests continue. This is because we want to know how long systems last so that we can give our customers the best possible service life estimate.

Your advantages with CFCLEAN in conjunction with the e-skin flat

The e-skin® flat has a modular design, and the individual pods can be opened. This facilitates maintenance. If unexpected cable breakage occurs in a conventional system, the entire system must often be replaced, or the cable must be pulled through all the pods, since they cannot be opened.

The e-skin® flat offers many advantages even during the design phase of the machine or system. The project engineers need not determine the entire cabling early on, since the system is easy to expand. All CFCLEAN cables are available from stock, so the system offers not only great flexibility in selection, but also speed.

Here is a summary of the advantages:

- No costly prototypes need to be planned at an early stage

- Deliverable from stock, so small series are possible

- Fast replacement in existing production plants

- Flexible design

Where have we already used CFCLEAN?

Various customers are already using CFCLEAN cables in conjunction with the e-skin® flat. For instance, a well-known manufacturer of linear motors decided to use the system because it is designed for high dynamics. In connection with cleanroom compatibility, we had two points in our favour, since these motors are used in a machine for manufacturing computer processors.

As described above, normal cables and conventional energy chains are often used. Here, we collaborated with Assembléon, a Dutch company, to develop a system designed for 400 million strokes in an SMD pick and place machine.

Do you have questions about CFCLEAN? We would be happy to help you with issues concerning cables for cleanrooms.