What is iglidur? And what does it do better than POM?

Lars Butenschön | 2. July 2020

Just recently I stumbled on this blog post, which promised to finally put an end to the mystery that seems to be iglidur®. What is iglidur? And why are customers willing to spend no less than a fortune on bearings made from this material?

To make this clear right away: I have no intention to bore you with a long monoligic defense speech to save the honor of iglidur®. To the contrary, I think the question about the ingredients and the “magic” behind elaborately labeled products is completely understandeable. While product quality and sustainability are becoming more and more important aspects in today´s world, saving on costs is still a very important matter to many companies. Therefore it is very common to ask “what exactly am I paying for here”.

And even value/price aside, most products require thorough documentation on performance- and properties, compliance to Norms and regulations. So it´s of course important to know what actual ingredients are and what properties they have.

So lets follow this train of thought and dive into the idea of the post I mentioned above. Let´s see what we find behind the curtains of iglidur® in particular and plastic bearings in general.

iglidur® vs POM – or versus what actually?

Trying to compare different plastics regarding their capabilities as a bearing material is not easy. To get an idea on why that is the case, we should take a look at what´s inside these plastics. Their are countless options here and many come with fancy names or claim to be enhanced versions of “regular” plastics. In fact, a reason for this huge variety is exactly this. Most engineering plastics are some sort of mixtures. They are called blends or compounds and are all based on the same limited range of so called base polymers. Typical base polymers in bearings are Polyamides (PA, PA6, PA46, PA66) , Polyoxymethylenes (POM) or – if it comes down to temperature resistance or more special abilities – PEEK, PSU, PPSU, PPS (sparing you the long versions) and a few others. But how do we compare these?

There is a plethora of more or less helpful tools for that. They range from to countless variations of the infamous “plastic pyramid” to data sheets and whitepapers on the web, trying to help you find the right material. And of course there is a ton of books on the subject in general. But how do you know, which to use for bearings?

Datasheets can help but don´t provide enough answers

Comparing datasheets is standard procedure. But at least for bearings, datasheets often lack practical parameters that are directly related to the materials suitability for bearings. Wear resistance for example depends on many different aspects. The coefficient of friction, which is an often used point from data sheets actually depends on many different environmental parameters. And on top of that, most plastic polymers are not vastly different from each other in many data sheet parameters. In fact, you will notice barely any difference in key properties like density, thermal expansion or even mechanical resistances for compounds which share the same base material. These properties can be altered to a certain extent using fillers and additives. They range fromreinforcing fibers or flame retardant to UV radiation protection agents.

However, while these ingredients individually only have a relatively small impact on the standard datasheet values, they greatly influence the wear and sliding behavior for bearings applications. Even very small adjustments to the mix can have dramatic consequences for the service life of a bearing. In our own material development projects, even small percentages of pigments we used for changing the colour of materials decided about failure and top performance in field tests.

POM is POM, right? Wrong

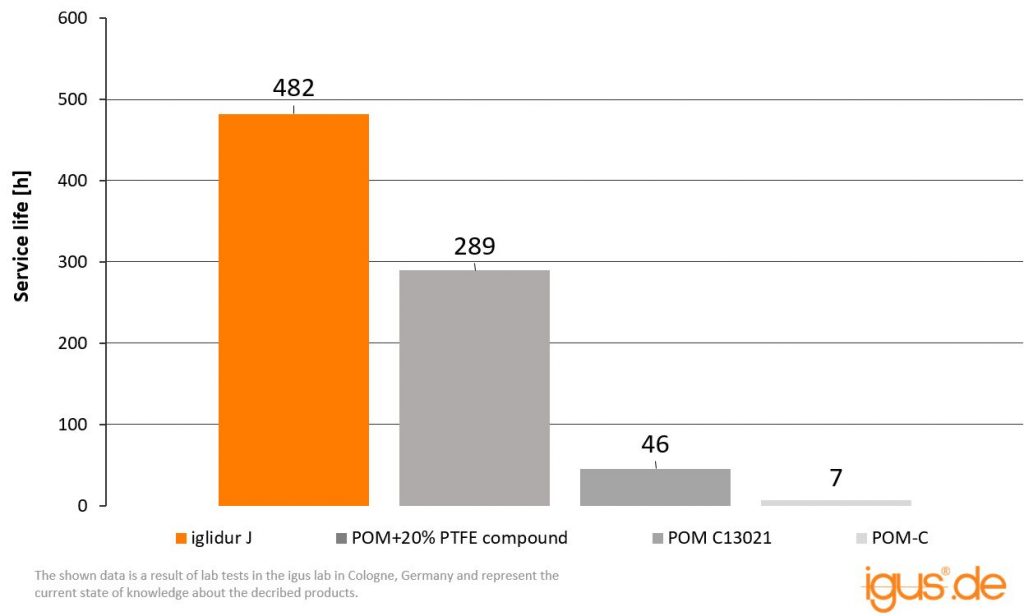

One of many wear analyses we did in our research lab helps visualizing this “phenomenon”. We test all our bearing materials – and of course also various competitor solutions – on our own standardized test rigs. Using this setup, we are able to determine the loss in wall thickness under realistic application conditions with adjustable parameters like load, speed, type of load and type of motion. Here´s a recent example of one of these tests, comparing the service life achieved by various bearing materials.

All bearings were tested in the same environment. A V2A stainless teel shaft, a load of 1 MPa, 0,3 m/s rotational speed, room temperature 23°C. We defined the end of service life by a loss in wall thickness of 0,25 mm. While the two POM variants without any fillers and additives broke down early with 7 and 46 hours of continuous movement, the POM compound with 20% PTFE lasted for 289 hours. This compound was surpassed by iglidur® J with 482 hours.

But how do we know, which material is the better bearing material?

Since 1964, igus® has been developing solutions for wear problems. And for about the same period of time our customers have been asking pretty much the same question. “And how long does the material last?” To answer this fundamental question, which fills pages and pages of engineering books (unfortunately focusing only on lubricated metal bearings), we decided to take a more practical approach. We developed a little tool called “iglidur service life calculator”, fed with real test data from practical wear tests.

For what must be ages now, wear analyses are done using so called pin on disk tests. However, we chose to go a different – more practical route, with the hope to find a solution that is just a bit closer to the reality of bearing applications. So we built test rigs that could run actual plain bearings made out of our materials with any type of load, speed and motion type applied to them. Other important parameters include different shaft materials, surface qualities, environmental effects like heat, extreme cold, sand, dust or chemicals. These where the application parameters our bearings would face in the field after all.

The beauty of data

Using the data gathered from more than 10.000 of these tests every year, we collected a huge datapool of wear and friction results in thousands of combinations of the parameters mentioned above. All this data is what feeds our service life calculator.

The result: A free- and open-to-use online tool with which you can compare more than 60 different bearing materials, ranging from low-cost to high-end polymer compounds and find the one bearing for your application. Whether you are searching for the best bang for the buck or the long lasting premium solution. Calculate, compare the different options and download the in-depth documentation and datasheets for your files – Trust is good, Control is better, isn’t it?

Why service life and reliability are often more important than price

So there it is. The bearing that can cope with all the loads and speeds you threw at it. Next on the todo list: price comparison. Often enough, price is one of the first selection criteria. And yes, price-wise, the differences can be astounding. Often, bearings are only a couple of cents a piece. Since in many applications bearings are required in huge quantities however, costs tend to rack up quickly. Especially in these applications, where hundreds of thousands or even millions of bearings are required, you may want to go for a cheaper low cost materials without pricey tuning ingredients.

Still, you should never determine the costs of your bearings only by comparing their price tag. In reality, the costs per bearing consist of more than just the purchasing price. And this is what all the fuss is about. This is the core of the question “How long does the material last” and “will I end up paying mainly for a fancy name – can’t I just use a basic polymer bearing?”. This is why asking these questions may be justified, but ultimately fall short. Yes, you – especially when you are a purchaser – want to keep the purchasing price low. And most likely, so will the end-customer of your product. Yes, the price should be as low as possible – but they also have to work and not break down early. Because the cost for bearing failure is often times way higher.

Knowing how long a bearing will last is invaluable.

The costs for poorly selected bearings is immense. Depending on the machine, it can be a pain in the but to get the old bearing out and replace it with a new one. You need to shut everything down, the maintenance-guy needs to disassemble everything around the bearing to get to it….just to replace a toe-sized machine part that helped saving an enormous amount of 25 cents on the 80.000 dollar machine. Imagine other applications. The corn harvester breaking down in the field during a stressful harvesting season with a time-window of only a few days. Or the 2.500 dollar Mountain bike starting to rattle and squeak on that perfect mountain trail in that perfect weather condition. Costs for poorly performing bearings is high. Knowing how long a bearing will last is invaluable.

We love to support you!

Saving costs while improving the quality of moving parts in any device plays a key role in any industry. From cars to household appliances, manufacturing machines or electronics – everything needs to perform better and better while at the same time cutting down on costs. Selecting the bearing material with the best price/performance ratio is an important task. But so is creating economic and practical part design and optimising the bearing point in general. We assist you with all these tasks, personally. Online, by phone or on site.