What are initiator cables and where are they used?

Beke Nieszytka | 16. September 2019

Initiator cables, also referred to as sensor/actuator cables, connect control units and different sensors, or, in the case of reversal of the measurement principle, actuators. Frequently used abbreviations include ini or ini cable (plural: inis).

Sensor or measurement transducers transform physical quantities such as rotation, speed, distance or length into analogue electric impulses. In the case of an actuator, the measured electric current (symbol: I, unit: ampere; A) or voltage (symbol: U, unit: volt; V) is transformed into temperature, pressure or torque.

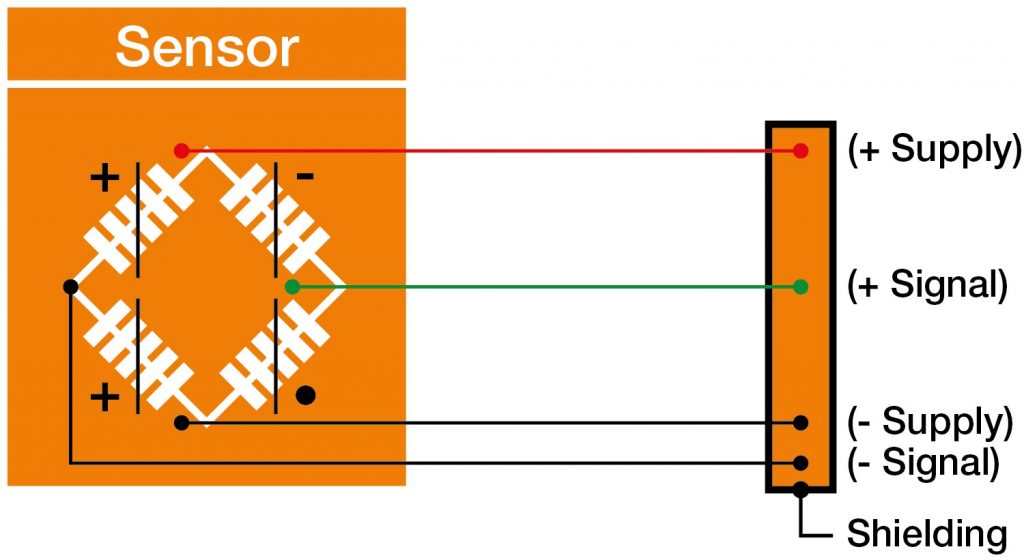

The connection cable consists of at least three cores with a small cross-section of between 0.14mm² and 0.34mm². In the simplest case, two cores are required for supplying the voltage, while the last core transmits an I/O signal. For sensitive applications, there are shielded versions in addition to the traditional ini cables to avoid EMC disruptions (electromagnetic compatibility).

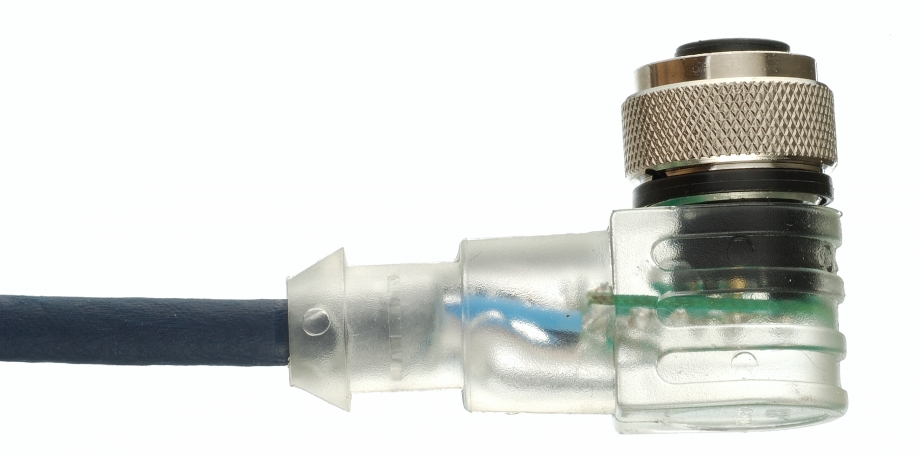

Initiators installed in the field are usually connected via M8 or M12 connectors with the appropriate number of poles. Modern production sites require numerous initiators to guarantee a smooth operation. Therefore, the required connecting cables are often mass-produced goods and are manufactured with widely automated processes. The cables are usually industrially moulded with M8 or M12 plug-in connectors. The moulding process not only ensures a high process capability, but also directly impacts sale price. In addition, a high sealing class, a very small installation size and a reduction in weight can be achieved.

Small but nice – the hidden mass-produced goods with potential

As described, many sensors and actuators are installed, which explains the demand for initiator cables that has reached a high level and is continuously increasing. Due to the rising degree of automation with new electromechanical constructions and plant, the number of installed sensors also increases. As these have to be connected to one another, in reverse more and more initiators have to be included in the construction. To simplify this, distribution boxes such as sensor/actuator boxes are used in the machine segments.

Nowadays, sensors can be found in large quantities in different industries – e.g., in the following:

- Machine and plant engineering

- Machine tools

- Factory automation

- Automotive industry

- Building technology

- Agriculture

- Aviation and aerospace

To connect the individual components with each other and ensure signal exchange, there are several providers who are specialists in this product area, so as to realise the connection of control unit and sensors. To name just a few of the most well-known:

- Phoenix Contact

- Belden/Lumberg

- ifm

- Keyence

- Binder

- Turck

- Murr Elektronik

- Metz Connect

- Balluff

- Escha

- Molex/Woodhead

- Pepperl & Fuchs

Example 1 for an initiator cable: CF.INI

How do I choose the right cable?

The choice is huge. But what is the difference?

The right cable depends on the application. As a first step, you should answer the following basic questions:

- What length is required?

- What core/cross-section combinations does my sensor need? (Number of cores, cross section of cores)

- What connector combination should the cable have to connect sensor and control unit? (M5, M8, M12, 7/8″, 1/2″ straight, angled, encoding – A, B, D)

- Is a shield or a certificate (UL, IPA, Food & Beverage (F&B)) necessary?

The cable should fulfil mechanical and chemical requirements. Questions come up such as:

- Is the cable moved a lot or is it permanently installed?

- If it is moved a lot, in which radius?

- Does it have to withstand oil or different chemicals?

All these and many more questions are the beginning of the design.

Here, both jacket material and design of the product sold by the metre are important. PVC is cost-effective and suitable for use with low chemical and mechanical requirements. If the cable is intended to be used in a continuously moving application with an energy chain, it should be suitable for use in energy chains and be oil-resistant, the outer jacket is usually made of the material PUR.

For use in extreme conditions, you can choose TPE as jacket material. As prices here are still moderate, it is recommended to consider this as well. That way, high reliability can be ensured. With highly complex plant you should be aware of the costs and effort involved – depending on the installation conditions – in the change of the cable compared to a possible machine downtime.

Example 2 for an initiator cable: CF.INI

The problem solver for heavy-duty applications: the CF.INI by igus®

igus® offers a problem solver for such highly complex “heavy-duty” applications. Our sensor cable CF.INI has an outer jacket made of TPE and enables extremely small bend radii. Even with millions of cycles, igus® guarantees predictable functionality. With our service life calculator for cables you can calculate the service life of your custom cable in advance.

Has CF.INI sparked your interest? Find your right sensor/actuator cable here. We are happy to provide you with a sample cable upon request.