Unusual requirements and how to fulfil them Customised cables from igus

Stefan Wehrmann | 12. August 2021

“Can I get that in pink?” Admittedly not a frequent request when it comes to cables. But there are requirements that our catalogue goods cannot meet despite the great scope of our product range. Such cases require customised cables.

This article will focus on this topic and present some basic data in more detail.

What is a customised cable, and when is it needed?

In the course of my career, I have been involved in project planning for many customised cables. The requirements could not be more varied. For instance, the changes were frequently adaptations of standard products to other outer jacket colours, or simple core cross section combination changes.

Project planning for true special solutions requires much more effort.

Such a solution might involve several cable types combined to form a single cable, for instance. Providing the customer a satisfactory solution requires a great deal of experience and expertise.

Personal experience with customised cables

I well remember my first solo project planning effort for a customised cable. A customer from Argentina needed a data cable with multiple core pairs and a bus element. At the time, this was a real challenge, since the processes were still new to me and my contacts to the development and production departments were not yet firm. After many hundreds of project planning procedures, all that is no longer a problem. The details of trade standards, etc. have also become second nature to me.

Working carefully in preparation, project planning, and the ultimate offer remains important. This is the only way to ensure that the customer gets a product that is perfect for him.

How do I get a customised cable?

Let’s get down to the actual process of requesting a customised cable. Before project planning can start, there is always a personal conversation with the customer. This can also be done by video, of course. It provides an excellent foundation for discussing requirements in detail and explaining options. The most important considerations are:

- Desired number of cycles or service life

- Additional mechanical requirements

- Electrical requirements

Moreover, there is an important item that needs to be cleared up: the target price.

It helps no one to discuss a technically sophisticated solution and then find out when it comes time to make an offer that the budget does not cover the product.

A special solution requires a bit of project planning and production effort. This means that a customer can get an economic offer starting at a purchased quantity of about 3,000 m. This minimum purchased quantity varies by cable type and configuration.

Project planning for a customised cable

While customers can just send catalogue cables to the shopping cart and usually buy them right away, customised cables must first be planned, manufactured, and tested. This process takes a bit more time. After all, the final cable should be able to do something that other cables can’t. We’re talking about an exclusive special design.

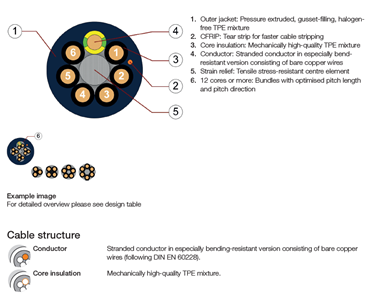

Our experts employ detailed user information and technical data for their project planning for customised cables. They can build on standard products or select a completely new structure as necessary. After project planning and direct coordination with our production team, we send an offer to our customer. The offer has a detailed structure and contains information on the cable structure and mechanical and electrical properties.

Ordering a customised cable

After the customer has reviewed the information and conditions, he places an order with us. We then create a detailed technical data sheet. To ensure the greatest possible quality and reliability, the data undergoes a proven triple-control procedure before it is sent to the customer. It is only after the development department, product management, and the responsible salesperson have given their OK that the customer receives the final documents. When they have been approved in writing, the official order procedure begins, and the product is delivered after the relevant production period.

Excerpt from a chainflex data sheet:

What are typical delivery times for customised cables?

From the process described here, it is easy to see that several weeks might pass between initial query and ultimate delivery. Since each cable is planned and manufactured individually, it is difficult to give a general answer about expected delivery times.

Conclusion

Customised cables are specially produced and can be problem-solvers for our customers. They range from modifications to our standard cables to completely new designs. With such a cable, the customer can implement his individual preferences and plan the cable entirely according to his requirements. Such requirements might include a special colour or an unusual core cross section combination.

We would be happy to advise you and work with you to configure a customised cable to completely meet your requirements. We look forward to hearing from you.