Unique service: determine service life of 3D printed polymer components

igu-blog-adm | 5. February 2021

Unplanned machine downtime is a horror for any engineer, especially as a failed component can, with a bit of bad luck, lead to serious damage of the machine. The associated costs and effort cause considerable trouble for many companies. Very few manufacturers are in a position to state the expected service life of their components. In most cases, the machine builder must be prepared to regularly check whether signs of wear indicate that replacement is necessary soon. Another way to prevent machine failure is to invest time and money in replacing components that are likely to be in use for a long time.

But what if you could also determine the service life of special parts in advance?

igus has always been committed to testing the service life of components from its own production through extensive tests in the in-house laboratory. The data is made available to our customers without restriction. And what applies to the proven bushings made of iglidur also applies to components with individual dimensions and geometries, which are produced in additive manufacturing. The service life calculators for 3D printed gears and plain bearing bushes are already available online and accessible without registration – a universal service life calculator is under development. But all the data is already there and today customers can obtain the determined service life for their special parts made of iglidur polymers with a simple request.

What options are there to determine the service life of printed components made of iglidur?

1. The gear service life calculator: Using this proven, registration-free online tool, the expected service life of iglidur gears can be determined. It is possible to combine iglidur gears with gears made of metal and other plastics. Once the calculation is complete, the tool gives tips on which modifications could give the gear an even longer service life. Tom Krause, head of additive manufacturing at igus, presented the tool in an online workshop:

2. The plain bearing service life calculator: The “Bushing Expert” makes it possible to find the best iglidur material for one’s own plain bearing by specifying the application parameters. Injection-moulded bearings from the igus catalogue range as well as 3D printed bearings are taken into account. With some adjustments and supplementary calculations, the service life calculator of the plain bearing can also be used to calculate other printed components.

Instructions for calculating the service life of any wear-resistant parts with a rectangular sliding surface

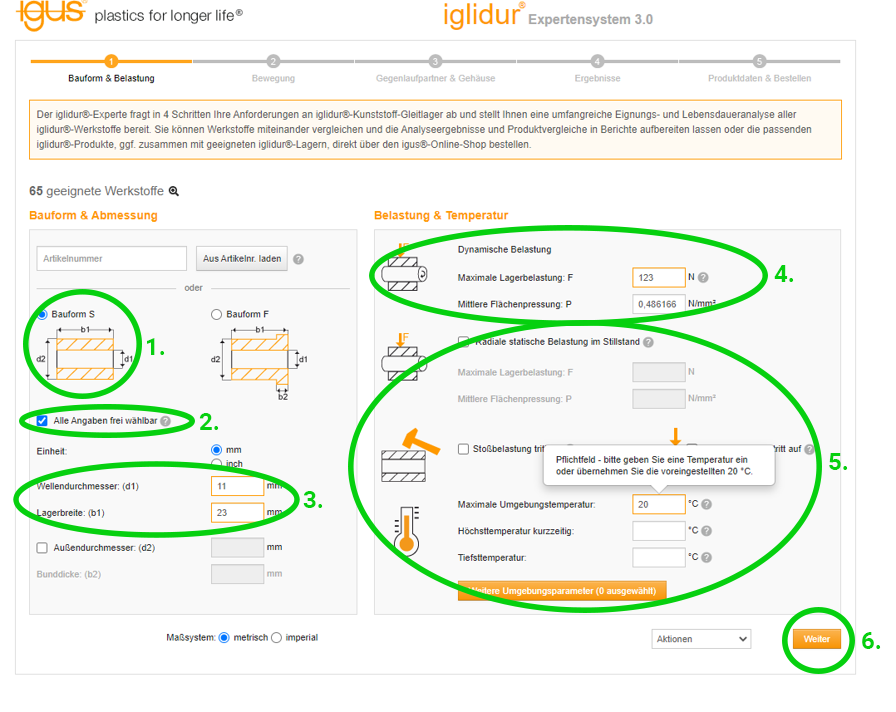

1. Select type S

2. Select “Choose all specifications freely”

3. Enter the width and length of the sliding plate (width for shaft diameter and depth for bearing width).

4. Enter fill weight

5. Enter further parameters (if necessary)

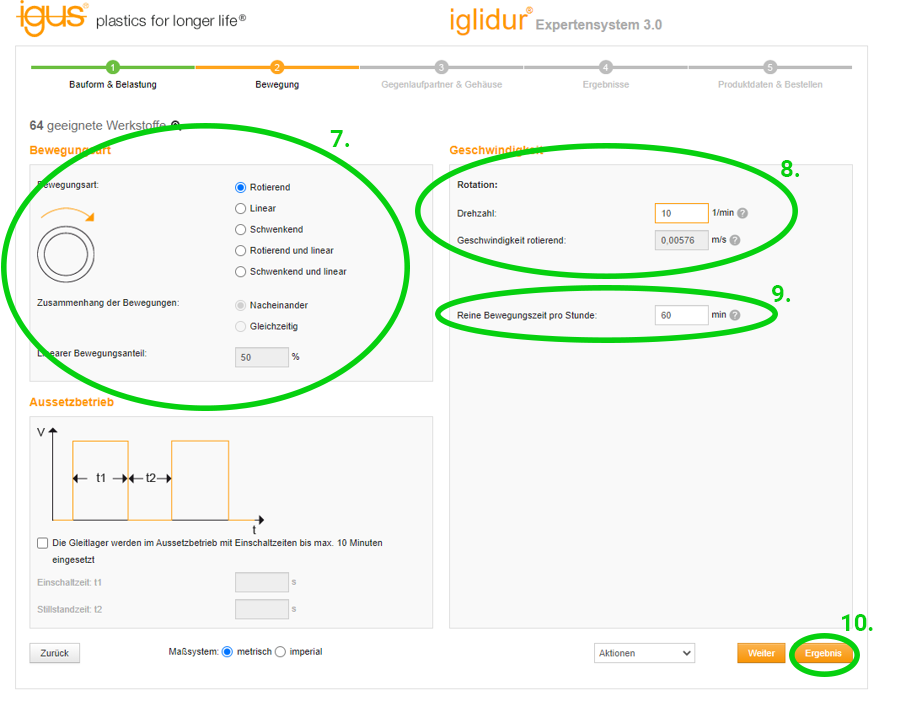

6. Click on “Next”. Specify the type of movement relative to the counter partner (more rotating, more linear or more pivoting)

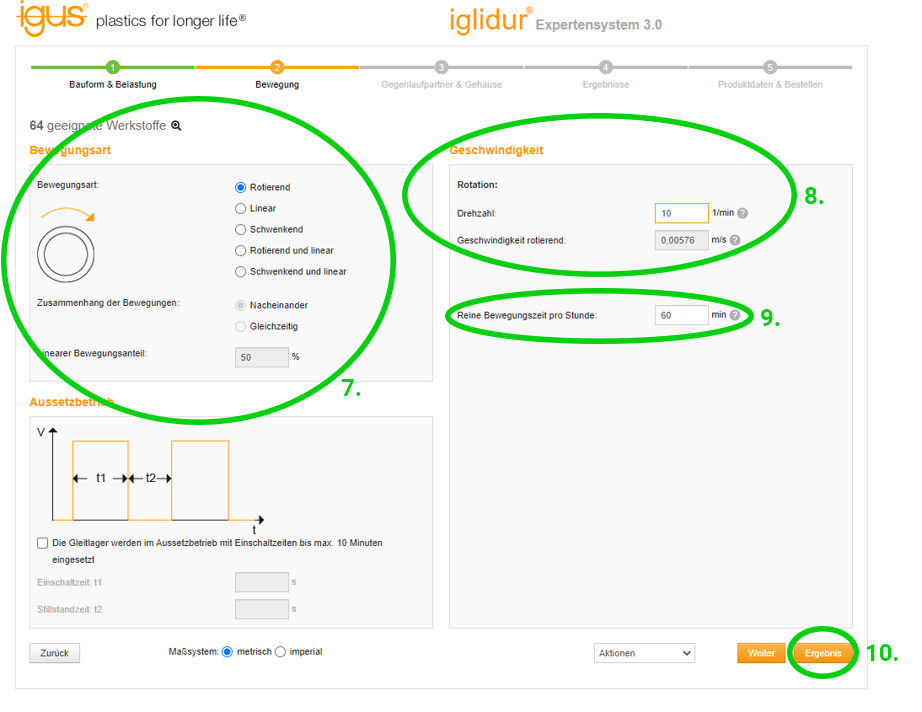

8. Calculate the speed depending on the type of movement by entering the speed, frequency or stroke distance so that the same sliding speed is obtained in m/s as in the actual application

9. Enter percentage of pure movement time

10. Click on “Result” to obtain the service life of iglidur polymers under the specified parameters or click on “Next” to select a counter partner.

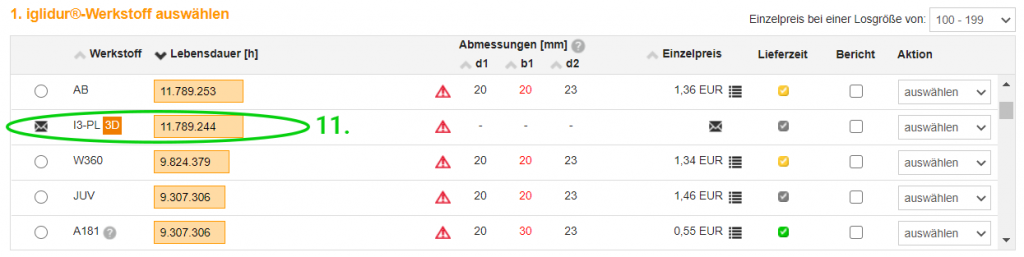

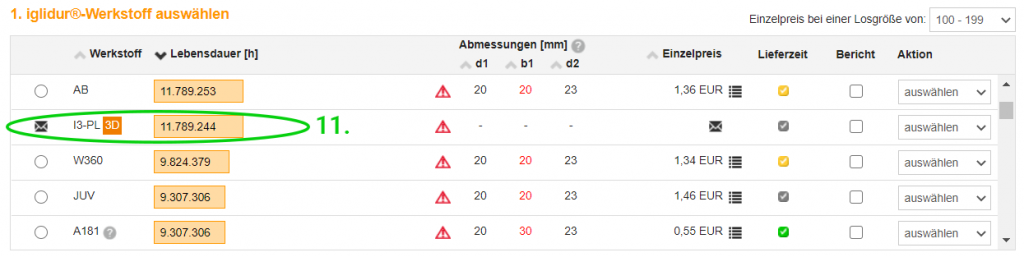

11. The expected service life in hours for your printed component made of iglidur 3D printing materials can be found in the materials list

To calculate the service life of wear-resistant parts with any shape

1. Select type S

2. Select “Choose all specifications freely”

3. Set width and length, e.g. 10mm each (width for shaft diameter and depth for bearing width)

4. Calculate the mean surface pressure and enter the fill weight so that the mean surface pressure is the same as in the application.

5. Enter further parameters if required

6. Click on “Next”

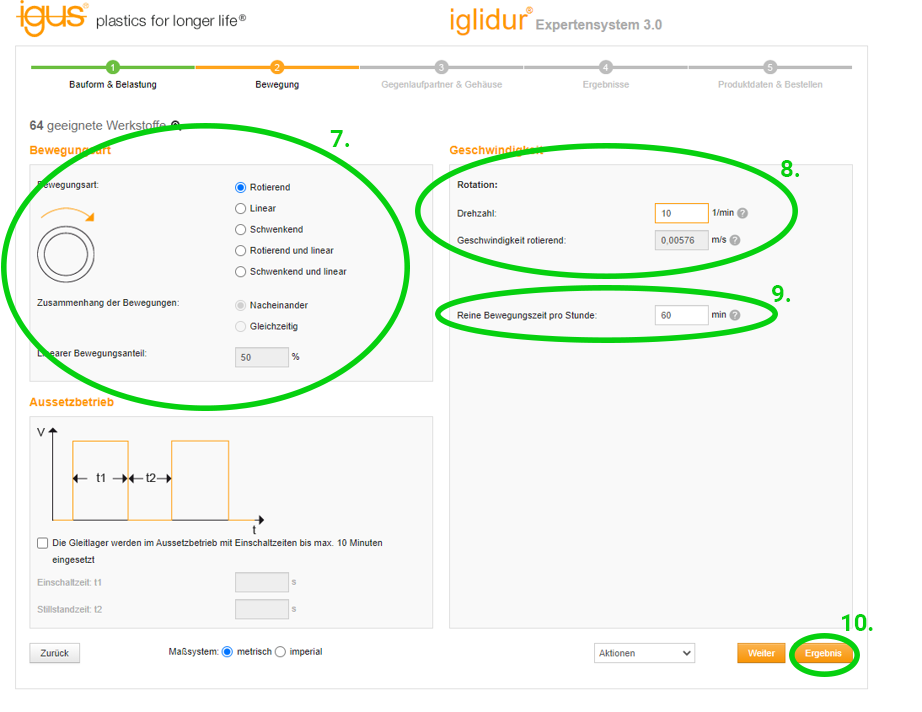

7. Specify the type of movement relative to the counter partner (more rotating, more linear or more pivoting).

8. Calculate the speed depending on the type of movement by entering the speed, frequency or stroke distance so that the same surface speed in m/s is obtained as in the actual application

9. Enter percentage of pure movement time

10. Click on “Result” to obtain the service life of iglidur polymers under the specified parameters or click on “Next” to select a counter partner.

11. The expected service life in hours for your printed component made of iglidur 3D printing materials can be found in the materials list.

Individual service life determination for printed components

The online service life calculation offers a good opportunity to quickly and easily get an impression of whether the iglidur polymers are suitable for use in one’s own application. If you need more precise information as part of product development or when looking for a new, quick source of spare parts, our engineers will determine the service life of your component for you. This way, they can clarify questions and provide individual information on the specific application. To determine the service life of individual 3D printed components made of iglidur, please fill out the form as much as possible and upload your 3D model. Our engineers will contact you by the mode you prefer.