Thread size 10×3

Zoe Moser | 4. February 2021

What is the thread dimension 10×3?

The thread is a profiled indentation that runs along a helical line wound around a cylinder. The type of thread is defined by the profile shape, the pitch, the number of threads and the direction of rotation. You will find more terms all about threads and lead screw drives explained in another blog post. Basically, lead screw drives are machine elements that convert rotary movement into linear motion.

In this blog post we look at one of the common thread sizes: the 10×3 thread size. For all questions, please contact Stefan Schulze Pröbsting, Product Manager of dryspin® lead screw drives.

Question: hello Stefan, what is meant by the term “thread size” and what does the designation 10×3 tell us?

Answer: hello. The thread size describes the outer diameter and the pitch of the lead screw, i.e. the basic dimensions of the lead screw.

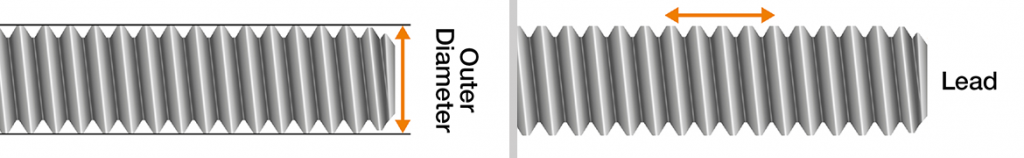

The outer diameter is the distance between the outermost edges of the opposite lead screw flanks. It is always defined by the first of the two numbers for the thread size. In our example, this is 10 [unit of measurement]. The unit of measurement is usually defined by the used thread geometry, for example trapezoid [DIN ISO 103] (TR10x3). In this case, the unit of measurement is millimetres [mm], whereas the ACME thread, for example, is given in imperial measurements.

The pitch, on the other hand, refers to the distance measured parallel to the axis between two adjacent and parallel thread flanks of the same thread. It indicates in mm the linear travel per revolution of the lead screw. In our example, this is 3mm. The same principle applies to the unit of measurement of the pitch as also to the outside diameter.

Question: what types of lead screws does igus® offer in 10×3?

Answer: in our range we offer three main types of lead screws. We have a small selection of metric lead screws, which we classify as our miniature range. The sizes offered are M3, M4, M5, M6, M8 and M10. These are typically combined with our SLN miniature thread module system.

Our standard lead screw range includes a huge selection of trapezoidal threads, in sizes TR8x1.5 to TR50x8 as standard. In special cases, larger sizes are also possible.

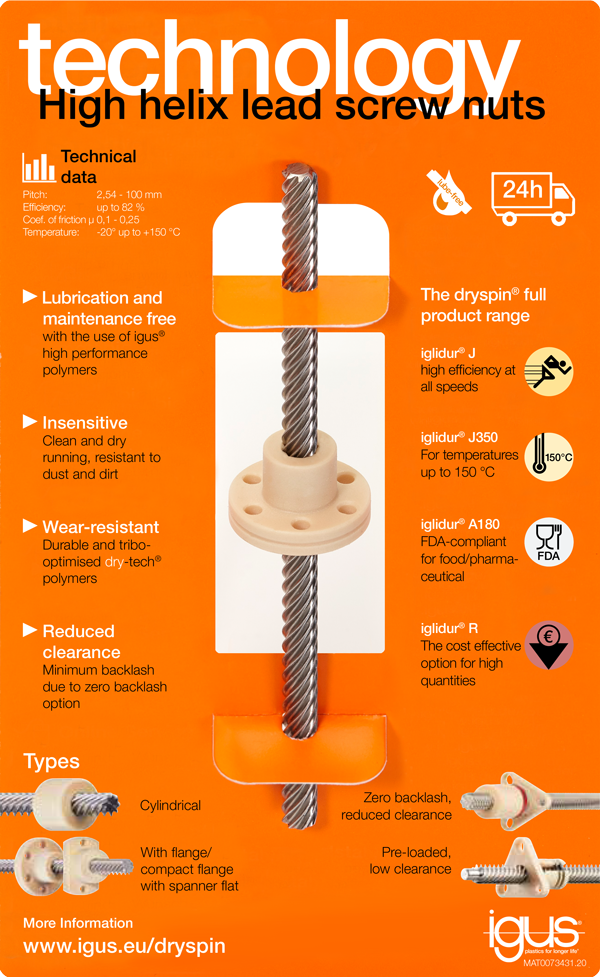

The high helix lead screws are part of our dryspin® range, which is specially designed for fast and very efficient applications. Thread sizes from DS4x2.4 to DS20x90 are available here.

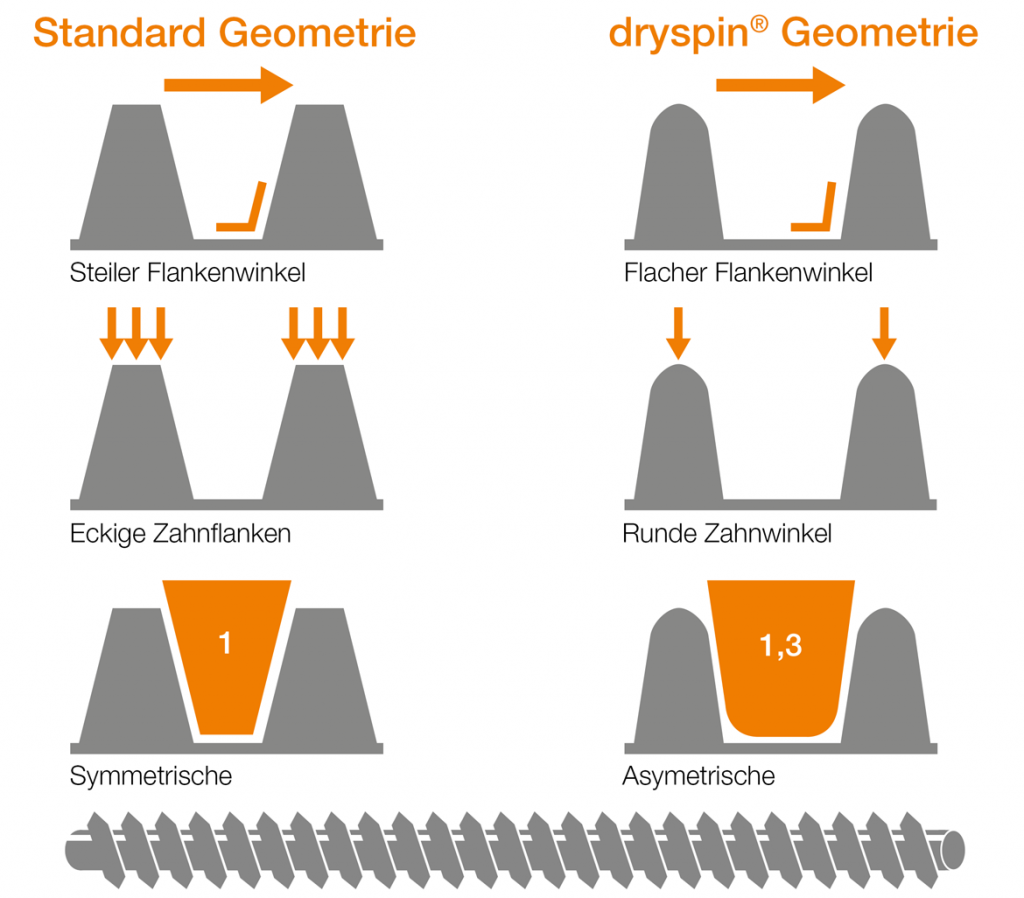

The dryspin lead screw technology was developed and patented in 2016 by the drylin lead screw technology development team. Particular emphasis was placed on increasing service life and improving efficiency. The dryspin product portfolio includes high helix lead screws made of stainless steel or aluminium, which are available in pitches from 2.4mm to 100mm. The dryspin high-helix thread geometry is an extension of conventional thread technologies such as metric and trapezoidal threads with numerous benefits. You can find more on this topic in our blog on dryspin® technology.

Question: what are the main general advantages of igus® lead screws in trapezoidal, metric, ACME and high helix threads?

Answer: as with all igus products, we have a variety of advantages compared to conventional solutions. Thanks to the use of tribologically optimised polymers, we can offer serious advantages in many industries and applications. Our products are characterised, for example, by maintenance-free and lubrication-free systems, cost-effective purchase and use, high resistance to dirt and other media, corrosion-free, FDA-compliant materials, predictable service life and deliveries from stock. You can find more advantages of dryspin lead screw technology here.

In the range we have many standard nut materials, which improve various applications with different environmental requirements. We also stock a wide range of lead screw materials from which we can machine standard or customised solutions.

Question: okay, and what are the advantages of dryspin® technology in 10×3 compared to the other thread geometries?

Answer: we have summarised the advantages in key points:

► Up to 25% longer service life due to asymmetry

► Up to 82% higher efficiency due to optimised flank angles

► Ideal sliding properties

► Quiet and vibration-free operation due to rounded teeth

► 100% lubrication-free and maintenance-free

Question: can the advantages of the 10×3 thread size also be proven on the basis of values?

Answer: of course. All of our products are put through their paces in our test laboratory with over 3,800m², of which linear technology accounts for over 300m². Finally, our products are designed with great passion to extend the service life of machines and applications, eliminate maintenance and reduce costs. For many engineers, the quality and safety of machine elements, i.e. their resilience and service life, are important criteria in development. All this data is essential for the new and further development and predictability of the materials. Online, igus offers numerous tools free of charge to help with the selection and purchase of the right products.

We also did this before launching the new DS10x3 dimension. Let us take a closer look at this representative test:

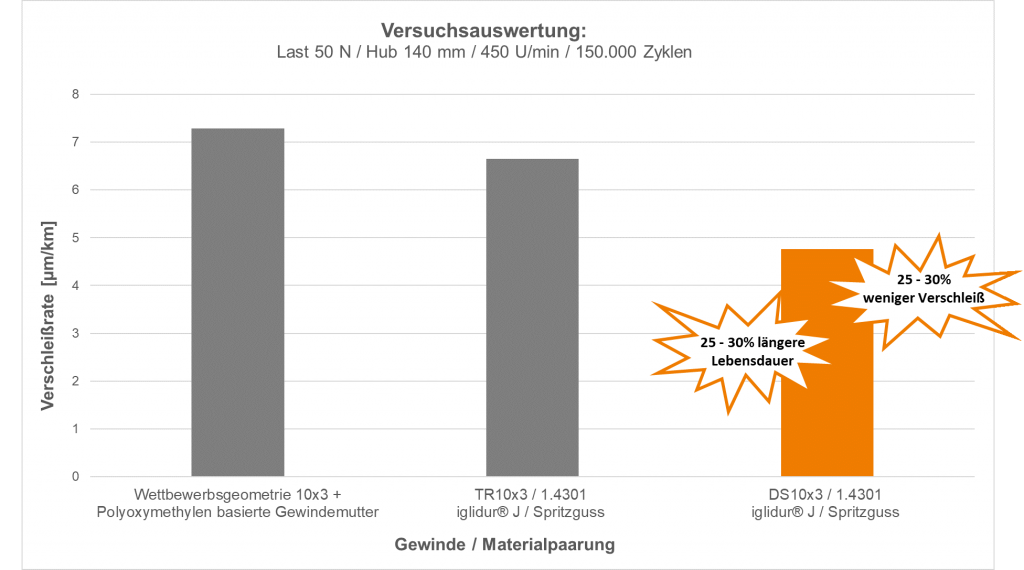

Task: wear analysis (thread 10×3; competition thread/trapezoidal thread/dryspin® high helix thread)

Tested lead screws:

1. Lead screw 10×3 of competitor’s geometry & polyoxymethylene-based lead screw nut

2. Trapezoidal lead screw Tr10x3 & iglidur® J lead screw nut

3. dryspin® high helix lead screw Ds10x3 & iglidur® J lead screw nut

Test parameters of the tests:

lead screw: competitor’s lead screw 10×3/Tr10x3 DIN 103/Ds10x3

Lead screw length: 20mm

Material pairing: iglidur® J/1.4021 (competitor’s geometry)

iglidur® J/1.4301 (trapezoidal thread & dryspin® DS

thread)

Load: 50N

Stroke: 140mm

Speed: 450rev/min

Test duration: 150,000 cycles

Question: what about the other technical data for the 10×3 dimension?

Answer: here we have some more technical data:

Dimensions:

gradient: 3.0mm

No. of threads: 2

Pitch angle α: 5.45°

Outer diameter Ø d1: 10.00mm -0.1

Core diameter Ø d3: 7.9mm -0.1

Max. length: 3,000mm

General specifications:

material stainless steel: AISI 304

Weight: 0.62kg/m

Manufacturing and installation tolerances:

gradient deviation: 0.1mm on 300mm

Straightness (standard): 0.3mm on 300mm

Aligned: <0.1mm on 300mm

Can be ordered via our configurator.

Question: are dryspin® products supplied as standard or can a customer request them tailor-made for their applications?

Answer: flexibility is the key here. As with all igus® products, we strive to offer the customer the best technical solution that works at the best price. In the lead screw sector, this means in concrete terms that if the customer needs machining on the lead screw, then we offer him these services. This applies to every type of lead screw we offer. Through individual processing, we not only reduce logistics, but also the administrative effort for the customer. In the online shop you can choose from a wide range of standard parts, e.g. lead screws in cut lengths and lead screw nuts in various standard geometries, and at the same time optimise your procurement process through the parts available from stock.

► Go to lead screw technology online shop

In addition to our online shop, we also offer a free configuration tool: the lead screw configurator. It allows you to configure a completely customised lead screw. After completing the configuration, you will receive a price, a CAD file and a PDF drawing generated free of charge and without obligation.

You will find that by using the tool, incredibly complex designs can be created in minutes, saving you hours of design and drawing time.

► Go to lead screw configurator

Here you can see a few examples that can be generated by the tool in a few minutes:

Should you get stuck and not be able to show special processes via the tool, our experts are available for you at any time. Together with you, we will clarify all questions regarding thread sizes, their application and the suitable lead screw nut material. Just fill out the contact form and we will address your concerns. We look forward to your message.

Question: how are these lead screws driven?

Answer: that depends entirely on the customer’s application. Typically, a lead screw drive is driven manually by hand or via a motor. The customer’s requirements determine how the lead screw is driven. In a packaging machine, for example, there may be rare format adjustments, depending on the product that runs through the machine every day. Irregular movements are usually carried out manually for cost reasons. Repetitive movements, such as product transfer mechanisms, which can have many cycles per minute, would then typically need to be motorised. They are part of a process that the machine performs. igus offers a solution for both drive options.

One final question: how can a customer find out even more about dryspin® lead screw drives?

Answer: in whatever way is most convenient for the customer. We have many opportunities to help with an application or simply to present the products. This can be in person, virtually or by phone. We have a team of engineers and local colleagues at customer sites waiting to help and assist regarding the application. You are also welcome to use various digital platforms to obtain further information about dryspin® lead screw technology. From our already mentioned tools, such as the expert system or the configurator for lead screws, and further blog articles and FAQs, to a wide variety of YouTube videos. For me, nothing beats personal contact. So if you need assistance with anything to do with lead screw drives, feel free to give me a call.