The team behind the igus:bike – The developers of the bicycle components

igu-blog-adm | 1. December 2022

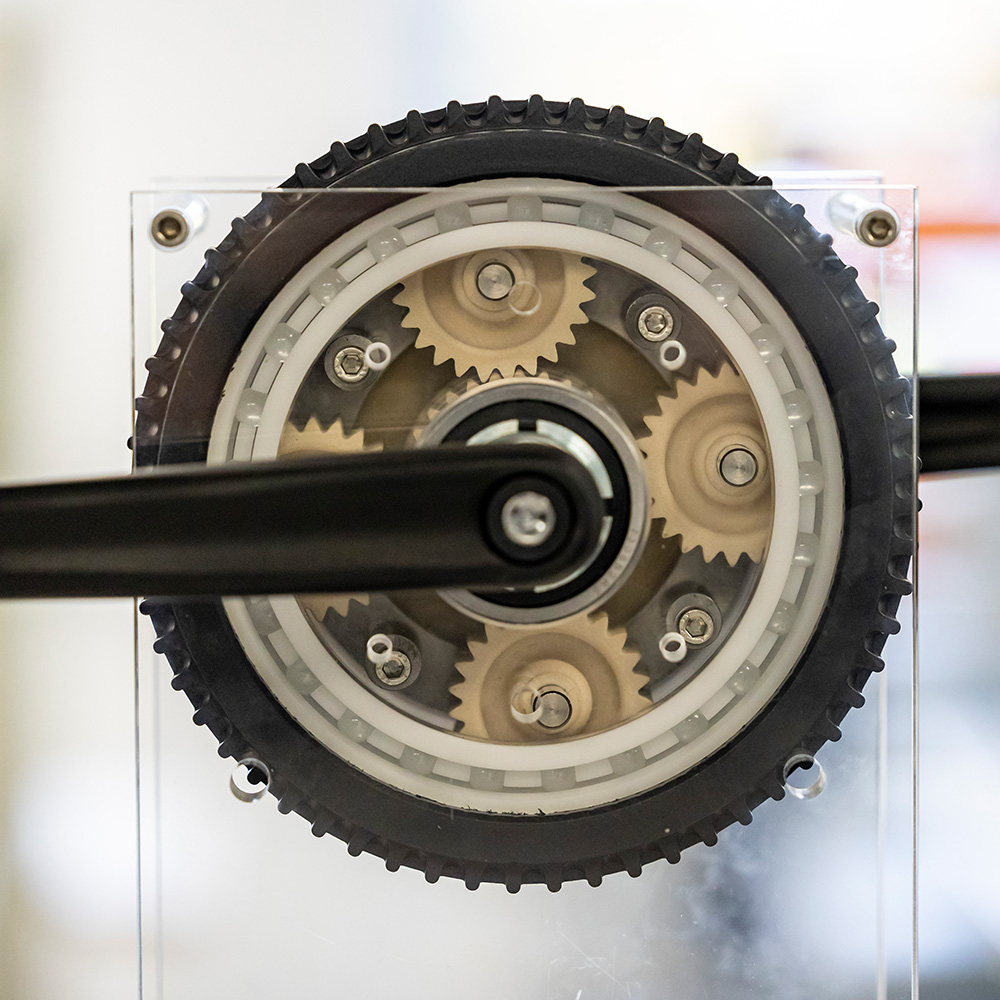

Gearbox, cranks, and pedals

Michael knows how to get everything running smoothly. It’s a good thing, too, since he develops the igus:bike gearbox, cranks, and pedals. So it is an ideal setup.

He has been working as a developer at igus for several years in gearbox systems for Low Cost Automation, comparatively inexpensive automation in the form of robotic components, which is also a very exciting topic. A year ago, the igus:bike challenge came in: develop a gearbox made of plastic. What could be easier? After all, there has never been anything like it before. That made the challenge all the more attractive. And for a cyclist, it’s more than just a “normal” project.

The first version of the igus:bike will still be a single-speed bike, meaning that it will have only one gear. Michael is already working on the successor bike, which will have two. In planetary gearboxes, the drive sprocket can be shifted to higher or lower gear with a short heel push to a large button. At the moment, this version is still in prototype status, and shifting is still a bit tricky. A number of tests will still be required in the in-house igus laboratory before high-volume production, but the breakthrough to the final version will probably not be long in coming. In addition to the shift function, he is also working on how the gearbox can be made lighter and more compact so that unnecessary weight can be eliminated from the igus:bike.

If you’re already developing the gearbox, it’s not a bad idea to take a look at the crankset attached to it. So Michael added that to his to-do list. And since no metal was to be used, he completely rethought a great deal of it. For the crankset to have the necessary rigidity, it has been given its very own shape. It is lightweight while remaining rigid, something only plastic can manage. The key was a design inspired by nature. The pedal is not screwed into the crankset, but attached to its pedal pin. This provides maximum stability. The pedal bearings are of course made of high-performance plastic and operate without lubricants, so they don’t need any maintenance. Speaking of the advantages of plastic components, they are not only maintenance-free, but also corrosion-free.

Are you interested in the people who develop ball bearings? Then you’re in the right place.

Would you like to follow the igus:bike project even more closely and never miss the latest developments, photos, and stories? Then follow the igus:bike Instagram channel.

More information about the bike and the project can be found on the igus:bike website.

Or would you like to pre-order the bike with its unmistakable design without any obligation? Then this is the right place for you!

brainstorminfotech

I appreciate you giving this fantastic knowledge. Only plastic is able to be rigid and lightweight at the same time. A naturalistic design was the secret. The pedal is fastened to its pedal pin rather than being screwed into the crankset. Maximum stability is offered by this.