SmartSlice now supports iglidur I150 and iglidur I180

igu-blog-adm | 4. May 2021

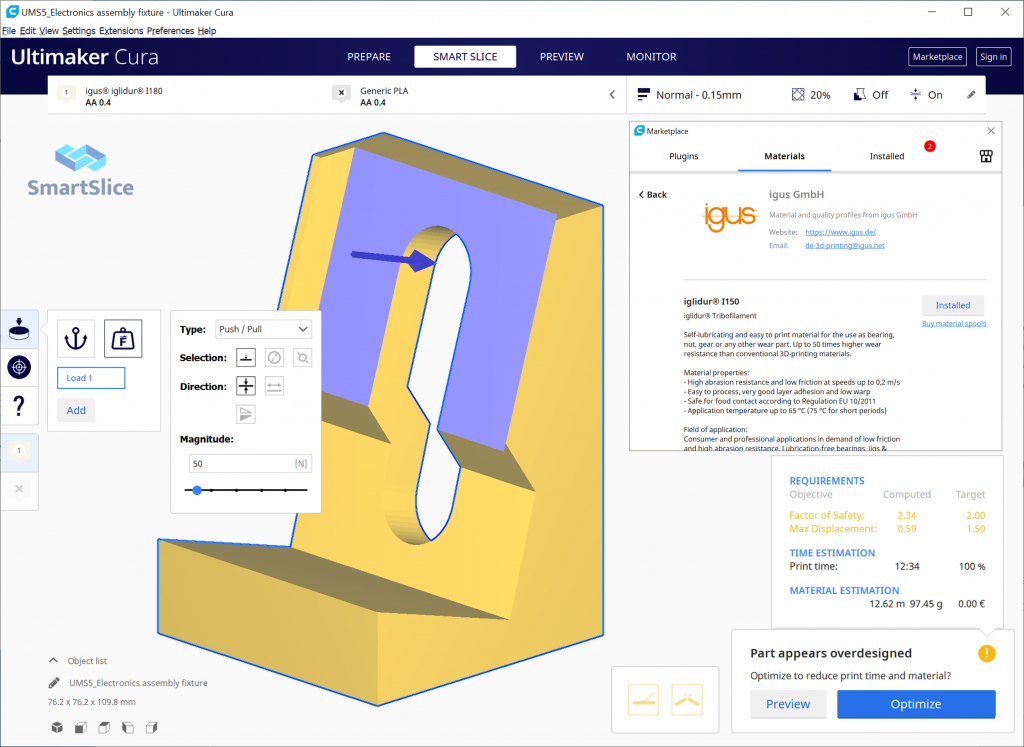

SmartSlice is a plug-in from Teton Simulation for the Cura 3D printed slicer. With SmartSlice, users can assess the components before the actual printing. It is a finite element simulation plug-in that uses material parameters and simulation technology to calculate the durability and deformation of printed parts before they are even printed. All inputs to the loads are made directly in Cura, so there is no need to procure simulation software. This also allows users to determine the optimum print settings with the lowest possible material usage and simultaneously guaranteed durability without having to carry out several tests beforehand. This process – also virtual prototyping – makes it possible to reduce the use of materials and shorten development times.

Update brings new igus filaments into play

Starting with the latest version (SmartSlice 20.2), iglidur I150 and I180 can now also be found in the igus polymer filaments . All that is required is to install the print profile from the Cura Marketplace and the respective material can be tested virtually.

The filament iglidur I150 is just as easy to process as the standard filaments PLA and PETG and at the same time offers high wear resistance thanks to its integrated solid lubricants. The all-round material is suitable for most applications and 3D printers. It is characterised by good mechanical specifications such as strength, toughness and layer adhesion and is food compliant according to EU 10/2011. Moreover, iglidur I150 is suitable for printing particularly large components of up to 3 metres in size.

The filament iglidur I180 has been specially developed for moving applications and is particularly suitable for wear-resistant parts such as plain bearings, gears and drive nuts. In addition to high wear resistance, the filament is characterised by its strength and temperature resistance. Components made of iglidur I180 can be used at an application temperature of up to 100°C and are also suitable for highly dynamic applications. Enclosed 3D printers are particularly suitable for manufacturing with tribo-filament, which is available in white and black.