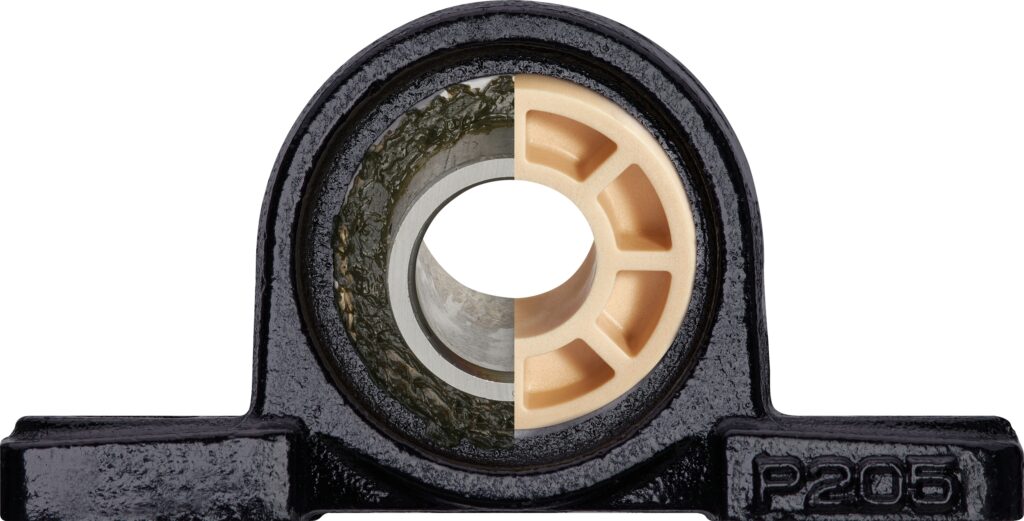

Save grease effectively with lubrication-free spherical insert bearings!

Tom Schrage | 3. August 2022

Our world is constantly on the move and the machines that meet our needs are running around the clock. And regardless of whether it is guide rollers, construction machines or robots, where things are in motion, there is friction between the materials, which in some cases are exposed to high loads as a result. Every child knows it: friction creates heat. And although this is fun for children to experience the first points of contact with heat by rubbing their hands together, this poses major challenges for designers in an industrial context, where metal rubs against each other. The metallic components lack a decisive factor: lubrication. Lubricating grease is therefore used on a large scale as the means of choice, which not only entails high maintenance requirements due to regular lubrication, but can also lead to failures and thus downtimes, which can cost companies a lot of money.

Is lubricating grease an environmental hazard?

Anyone who has a driver’s license remembers: one drop of oil contaminates approx. 600 litres of groundwater. The problem of so-called “loss lubrication” is therefore accordingly disadvantageous. The reason for regular lubrication of the bearing points is due to the function of lubrication. During operation, this is slowly pressed out of the interior of the bearing points to the outside. In doing so, it reliably keeps dirt, dust and moisture out of the bearing point. Since the leaked lubricating grease is then released into the environment, its use is problematic. Last but not least, guidelines and regulations now ensure that use is limited to environmentally friendly lubricating greases. But these are significantly more expensive than conventional grease.

The solution? Lubrication-free spherical insert bearings made of high-performance plastics!

Bearings with igubal® spherical insert bearings enable dry operation without lubrication and are therefore maintenance-free. The spherical insert bearings are available in various high-performance plastics, each with different specifications. From extreme temperatures between -100°C and +250°C up to chemical-resistant, detectable for the food sector and underwater applications. There is a suitable material for every industry and application, making plastic spherical insert bearings a real alternative.

Advantages of igubal® spherical insert bearings

- Maintenance-free dry operation

- Lubrication-free

- Cost-effective due to less complex production

- Lightweight, due to simpler structure

- Easy assembly and disassembly

- Vibration-dampening

- Suitable to take high loads even for the long term

- Predictable service life

- Corrosion-free and media-resistant

- Resistant to dirt

Limits of igubal® spherical insert bearings

- Higher drive torques required in some cases

- Depending on the design, an additional fixing collar is required to secure the shaft axially

Undecided? We would be happy to assist you!

Our experienced application consultants will assist you in your application and work with you to determine the most appropriate solution. Free of charge, without obligation and easy, by phone, live chat, virtual consultation or on site. igus® has been manufacturing and supplying plain bearings since 1964 and supplies over 250,000 customers worldwide in a wide range of industries. Learn more