Repair of an vintage car speedometer with the help of 3D printing service

Guest author: Dr. Jörg Pühler | 18. April 2019

On the speedometer of my Stanley 750B from 1924 the mileage counter didn’t work anymore. It is a speedometer from Stewart-Warner, Chicago, type M-9.

Failure analysis

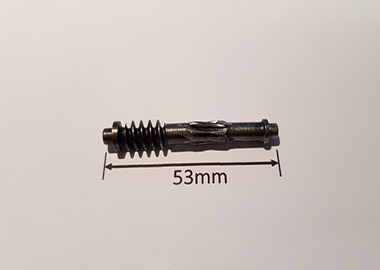

After dismantling, the mistake was obvious: the gear on the first intermediate shaft, which meshes with the worm on the input shaft, was completely ruined. The pinion was no longer in mesh with the worm. The “reworking” by a previous owner only made it worse – taking measurements was no longer possible.

Spare parts procurement! But how?

I could not reproduce this wave with my possibilities. Via the Internet, I came across the possibility at igus to produce gears by laser sintering with a special material using 3D printing. However, this requires the 3D construction in STEP file, which has to be created first.

Generate 3D model, use 3D printing service and receive component in a few days

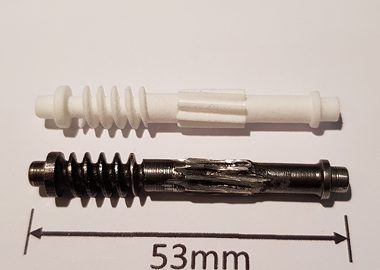

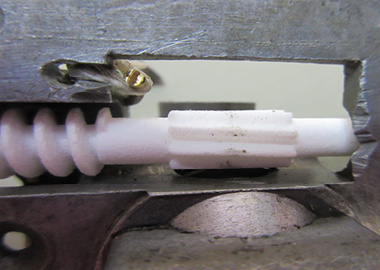

With the program FreeCAD, for which there are excellent tutorials on the Internet, I managed to create the CAD file in two evenings. Everything else went very fast: Upload the file – the price is displayed immediately, order and wait for delivery. The result was convincing. The material is sufficiently stable and even the smallest details are reproduced perfectly. The shaft fitted into the bearings right away and the worm for the output was also a precise fit. However, I had chosen a gear that was too small, I had estimated the wear of the old pinion to be too low. An advantage of this manufacturing method is the simple possibility of modification. Only one parameter in the CAD model had to be changed and the second version could be sent to print.

Amazingly good quality of the 3D-printed components

Original and replica next to each other. The precision of the printed part is surprisingly good. The surface feels slightly rough, but the bearing journals show no significant sliding resistance in the metallic bearing bushes.

The second model already ran quite well and passed a short endurance run. But at low revs it was a bit bumpy. After the diameter of the gear (= module) and the helix angle were adjusted again, the third exemplar ran perfectly round and had the correct intervention.

Lubrication-free and abrasion-resistant – 3D printing material igidur I6

The plastic shaft is not lubricated because the material iglidur I6 has self-lubricating properties. The minimal traces of metal abrasion originate from the worm drive and arose in the initial phase of the experiment, in the course of the 2000 miles they did not change noticeably.

For such parts, 3D printing by laser sintering with the appropriate material represents a cost-effective and durable alternative. The difficulty here is rather the creation of a sufficiently accurate 3D model, a little more effort at this point is appropriate.

Causes of gear wear

Before the endurance run, the speedometer was examined for possible causes of gear wear. The problem was found in the three-digit daily counter. The dials had about 0.2mm axial clearance and there is no spring washer that presses the dials against each other. During tests a small transfer gear occasionally slipped between the dials and blocked the counter. A slightly bent 0.1 mm thick brass plate was inserted at the side to eliminate the axial clearance and a blockage could no longer be observed.

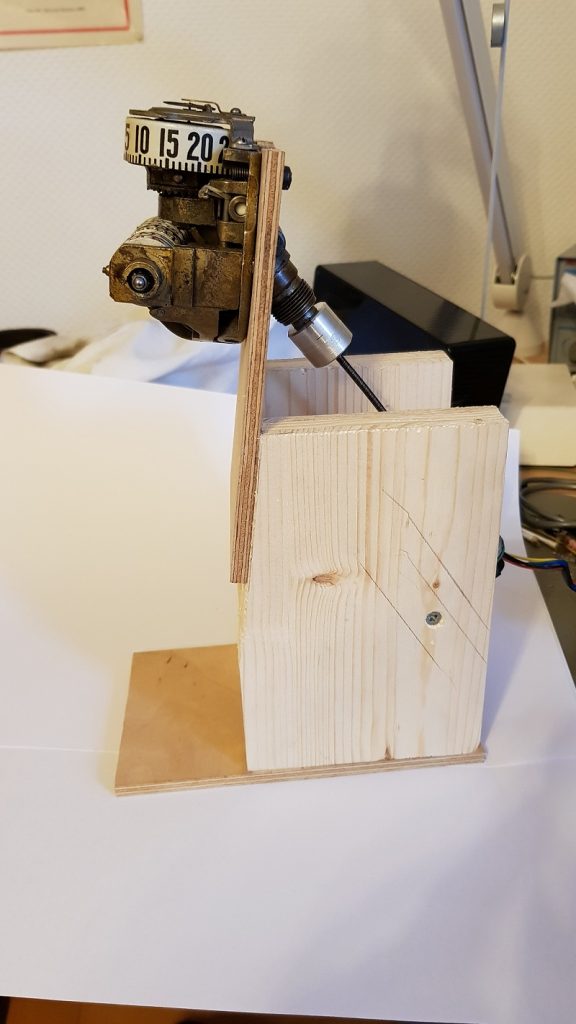

The speedometer was not defective. The display was 15-20% below the correct value. These speedometers have a steel magnet, which loses some magnetism in the course of the decades. With a small adjustment mechanism underneath the magnet the magnetic flux can be slightly changed, but this was far from sufficient to eliminate the error. The magnet wheel had to be magnetized. This actually requires an electromagnet that can generate a sufficiently strong magnetic field with a short current pulse. I tried it with several small neodymium magnets and was able to magnetise the magnet wheel sufficiently. Now you can easily calibrate the display with the slider. The display is absolutely linear up to 55 MPH, above that it shows slightly too little.

Bill Staub

Hi there. The idea of 3d printing a screw replacement for this oldtimer is very smart, I like. Would it be possible to use one of your photos (the one with the comparison) for a presentation on digital transformation for developimg countries?