Reduce costs in vending machine construction with reliable components

Andrej Schmidt | 31. March 2020

Whether the snack dispenser in an office, the reverse vending machine in a shop or an ATM on the street, they all have to perform their service without interruption, if possible 24/7. This alone is a great challenge for a vending machine manufacturer, as customers do not wait and, at the latest when they spend their money, do not tolerate any fault. An additional complication is the requirement of the vending machine operators: “The vending machine must be cost-effective.” “

It may therefore only cost a little, but must meet a high quality standard. How can costs be reduced without worsening or even improving quality?

Movement is what counts

For this purpose, we first consider the construction of a vending machine. In general, vending machines consist of a graphical user interface, a payment system, mechanical components to perform an activity and a software that combines everything.

The software controls the hardware, but cannot exist without the hardware. Software and hardware are therefore highly dependent on each other. Whereas the software is ideally written once and, assuming that the machine is not modified after development, it does not entail any further effort and costs, it is different with hardware components. Higher capacity utilisation, fluctuating environmental influences or improper operation by the customer lead in the worst case to the failure of mechanical components and ultimately to machine downtime.

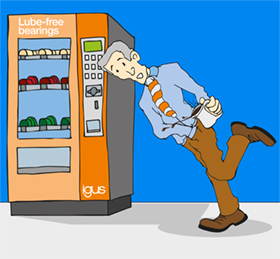

To prevent this, users like to resort to wear-resistant motion plastics from igus. Their specifications make them particularly suitable for use in vending machines. Just like vending machines, they are also characterised by the fact that they are cost-effective and versatile. Developers can rely on a wide range of products from stock. The maintenance-free systems enable smooth running without the use of lubricants for 24/7 operation.

Dependable 24/7 operation without maintenance

Vending machines can be found in the most remote places in the world. They are often located in difficult to reach places and are rarely maintained. This means that they have to work around the clock without disruption, otherwise there is no sales for the operator. To prevent unexpected failure of the mechanical components, igus offers aservice life calculation for all products online. The calculators are accessible to everyone without registration and are free of charge. After entering the application parameters, the recommendation of a product is made, specifying its service life. For this purpose, the tools draw on a pool of millions of sets of test data generated by igus in its in-house 3,800 square metre test laboratory.

Up to the defined wear limit, all products run without maintenance. For this purpose solid lubricants are homogeneously mixed with base polymers and composites. This enables a largely linear wear pattern, without surprises or maintenance intervals, to be observed. This saves time and money.

Technology need not always be expensive

Ready-to-use igus room linear robots are already frequently used in automatic lift systems. They can be individually configured without becoming more expensive than a standard linear robot. As the linear robots have a modular design, they can be flexibly adapted and enable a cost-effective complete solution for direct installation.

And if you decide on the DIY solution in the end, igus offers all necessary components from batch size 1 for development.