Reduce costs for injection moulded parts – With these 3 tips

Lars Butenschön | 16. July 2020

The design rules for the most cost-effective injection moulding designs apply to plain bearings in particular, to wear-resistant parts in general and to all other components anyway. The pressure to save costs is particularly high for plain bearings and wear-resistant parts. As “disposable parts”, these should last as long as possible, but also cost as little as possible. Buyers therefore often haggle over every penny in order to reduce the costs for injection moulded parts as much as possible. One important aspect is usually completely overlooked: the component design and its effects on the cost of the injection mould and production time. So let us take a look at the cost drivers.

Costs for injection moulded parts: The injection mould

Injection moulding is a fantastic production method for manufacturing large quantities of similar components. The proverbial millstone around the neck is the injection mould. While the idea is basically the same as moulding in a sandbox, the injection mould is often very complex. So-called undercuts or other special component shapes require small wipers or closing parts that subsequently block or remove certain areas.

In addition, a single “open-close” operation is often intended to release several parts from the mould at once. And since all moulds are a 3-dimensional mirror image – the so-called negative – the production of injection moulds is often very complex. This complexity, coupled with the fact that injection moulds are often custom-made, drives up costs dramatically. Finally, the manufacturer of the mould has to calculate all costs for the design and programming of the machining process, as well as the set-up and production costs, on one specimen. Added to this is the material of which the injection mould is made. The injection mould wears out with every production process. The more wear-resistant the material, the more expensive it is. In addition, some materials are more complex to process.

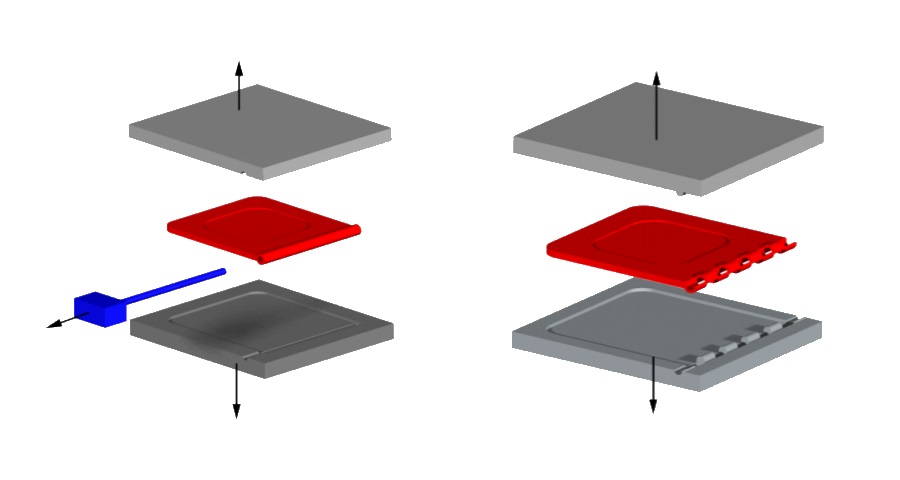

Tip 1: Simplify the shape of your injection moulded part

The simpler the moulding, the less complex the injection mould. In practice, an undercut that is only a few millimetres too large for the locating spigot can turn a €2,000 injection mould into a €4,000 injection mould. Avoid excessive undercuts or other shape features that could get in the way when separating the two halves of the negative mould. Protruding parts should preferably lie along the same axis.

Costs for injection moulded parts: The cycle time

Cycle time is the time that elapses between closing the mould and opening and ejecting the finished part. A lot happens in between. The liquid plastic is injected, fills the “cavity” – i.e. the negative impression of the component, it cools down and is finally ejected. The longer this process takes, the longer the production time of the entire order. A reduction of this production time brings corresponding savings.

Tip 2: Avoid complex and thick-walled areas

The longer the plastic takes to fill the entire part and the thicker the cross section of the moulds, the longer the material needs to reach all parts of the cavity and to cool down sufficiently.

Costs for injection moulded parts: The material

First and foremost, the procurement price of the material determines the part price. But also the nature of the material to be processed. Why? Because the material used has an influence on the wear of the injection mould. Plastics with a high glass fibre content have an abrasive effect on the surface of the injection mould. Accordingly, less time passes before necessary repairs or even a new production In addition, the thermal properties of the material can in turn have an effect on the mentioned cycle time.

Tip 3: If possible, use cost-effective and easy to process materials

Of course, in many applications there is no way around more expensive materials. Nevertheless, it makes sense to question the requirements placed on the component and select the appropriate material. Often, plastics are selected primarily because one has had good experience with them anyway, or because they were “just specified like this”. Also question the durability of the injection mould. Depending on the used component material and the required quantity, an injection mould made of aluminium or even plastic is often sufficient instead of expensive hardened steel.

We advise you!

We support you in the design of your polymer wear-resistant parts. In doing so, we determine for you the most cost-effective manufacturing process, the most efficient shaping and the optimum material for your application. We will assist you personally and free of charge online, by telephone or directly at your site.