Providing information for predictive maintenance with smart plastics i.Cee

Richard Habering | 3. February 2021

In today’s world, countless amounts of data is generated in a matter of seconds but the question is often asked, “What do we do with all that data?” The generation of data is one thing, but just as important is the provision of information or the form of information output. How does igus make the information output in Industry 4.0 accessible or visible to the user/applicant? This is precisely the question that often comes up in connection with the predictive maintenance solution i.Cee. In the following text, I would like to list the current possibilities and show the diversity of the system. As diverse as the applications are, just as diverse are the wishes of the user to receive information from the system.

Output option 1: text or CSV files

A very simple possibility is the output via a text or CSV file, where the messages are issued in asynchronous sequence. One also speaks of raw sensor data, which can later be prepared or processed by programmes such as Excel or other machines.

Here is a sample image of a CSV file with raw data.

Output option 2: via an FTP server

An FTP (File Transfer Protocol) server is used to exchange data between several computers within a network. This option can additionally be extended by an online option or you can limit yourself to the company network.

Output option 3: HTTP Dashboard via private IP address

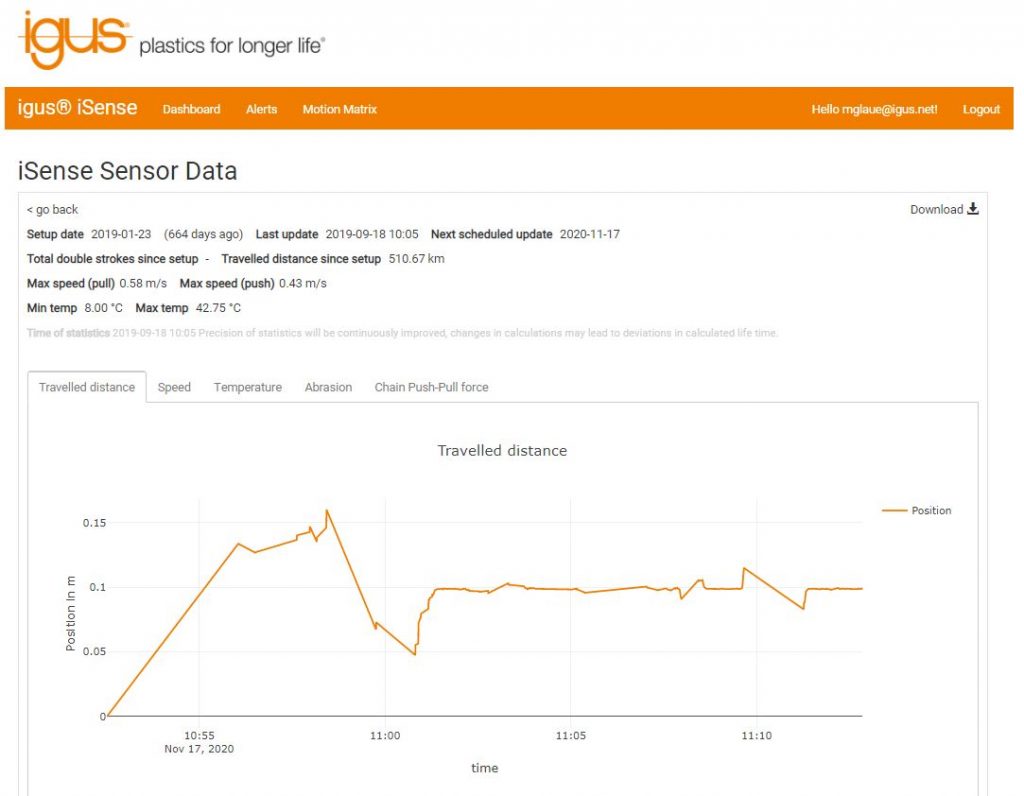

With this option, the data is processed in a dashboard via an IP address generated specifically for the i.Cee system. This is no longer raw data, as the dashboard directly displays the machine’s main sensor data in real time. The dashboard has an additional evaluation unit whereby data can be stored and analysed separately.

Sample illustration for a dashboard

Output option 4: dashboard via the igus IoT Cloud (i.Cee.cloud)

This version is very similar to the previously mentioned option (http dashboard via private IP address). The difference to the private dashboard is the update function. With the igus IoT Dashboard, more frequent updates are possible because many users use this interface and therefore the individual maintenance effort per user is significantly lower. Costs and time are saved which add to the improvements of the dashboard. This is currently the best solution in the smart plastics online sector.

Output option 5: OPC UA Server

This type of output is probably the option with the highest flexibility, as this technique is available for all common providers. Videos, even if they are in English, usually say more than a thousand words. Therefore, I recommend the video below to explain an OPC UA server.

Output option 6: text messages via SMS

It may sound a bit old-fashioned in times of Messenger or WhatsApp, but it is still a widespread way to send simple maintenance information or alerts to a certain group of recipients.

Output option 7: Siemens PLC

Of course, this option must also be available, because why not use what you already have? Here we are in the range of i.Cee. local, where the smart plastics i.Cee messages appear directly on the machine’s control panel. The connection to the programming interface takes place via Ethernet. In addition, the system provides a trigger for the message register.

Output option 8: through already existing monitoring systems

With this option, the i.Cee system delivers the data to a monitoring system. The raw data generated by the i.Cee is processed and prepared by the monitoring system. This has the advantage that existing systems are not changed but supplemented. An example from practice are the linear robots from Güdel.

Output option 9: JSON files / MQTT broker

This is another option where the i.Cee delivers raw data. The evaluation of this data is then again up to the user and requires the facility to process this file format. Certainly well suited for integration into Industry 4.0 projects but not a plug and play version.

Output option 10: Fanuc FIELD system

In this option, the i.Cee system is a module within the Fanuc FIELD system. The integration into the FIELD system takes place via an igus app.

Conclusion: “Information output in Industry 4.0 with i.Cee offers something for everyone.”

I hope I have been able to shed some light on the information output in Industry 4.0 and explain how the predictive maintenance i.Cee makes the generated information available. The above order does not reflect any ranking on feasibility. Ultimately, the customer/user decides how they wants the generated data to be displayed. The options range from pure raw data and raw data transfer to existing systems up to dashboards. With the igus dashboards, you also have the choice between locally or online retrievable data.