Plain bearings for CDC processes: self-calibration in six steps

Julio Pauli | 24. April 2020

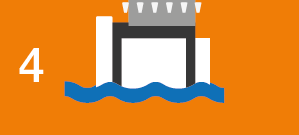

Plain bearings are used in motor vehicles in hinges, bonnet mechanisms, spoilers, boot hinges and seats. These points often feature rough mounts and collared grooves. iglidur plain bearings use the effect of heat in the CDC process to calibrate themselves, ensuring that they still fit in place exactly.

If you choose cost-effective iglidur plain bearings, you always get a quiet, lubrication-free, corrosion-free solution. Electrically conductive iglidur materials ensure an optimum coating result in the CDC process. Whether or not plain bearings in your application are exposed to high temperatures, media, or wear-intensive conditions, iglidur plain bearings are almost always a solution.

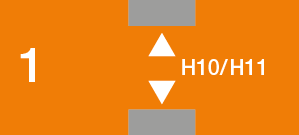

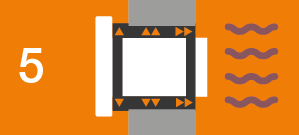

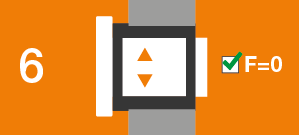

How self-calibration works

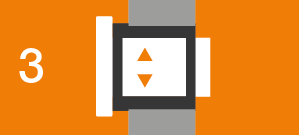

For plain bearings to be suitable for the CDC or e-coating process in the first place, they must be electrically conductive. Electrically conductive iglidur materials can be used. With the appropriate tolerance design, iglidur plain bearings can be calibrated during the drying process and are delivered to the end customer practically clearance-free . Bolts, rivets or shafts can further reduce costs. The polymer also adapts to the relatively roughly stamped mount under temperature .

These six steps allow iglidur plain bearings to calibrate themselves during the CDC process, making them almost clearance-free. You can find out more in this video: https://www.igus.eu/info/5-reasons-for-the-use-of-iglidur-plain-bearings-in-automobiles?

We would be happy to show you further advantages of our polymer plain bearings.

Feel free to contact me:

Julio Paul

Phone: +49(0)2203-9649-7042

e-mail: jpauli@igus.net

Free online consultation:igus Chat, Teams, Skype, WhatsApp, WeChat

Follow us on:linked.in, Instagram, Facebook

Enjoy browsing! Thank you for your time.

PS: plain bearings, spherical bearings, linear bearings, ball bearings, special sliders, gears or individually customised geometry – the iglidur Designer enables you to design your prototype component in no time and immediately receive price and delivery time information.

More information:automotive industry, polymer plain bearings forautomotive interior, exterior and engine compartment applications