Oil resistance for cables and cables

igu-blog-adm | 20. October 2021

Cables must always be selected according to the application and the external conditions. These include weather conditions, extreme or ambient temperature and also contact with oils. The oil resistance of cables is often indispensable. We shall clarify more background on the subject in today’s post.

Why oil-resistant?

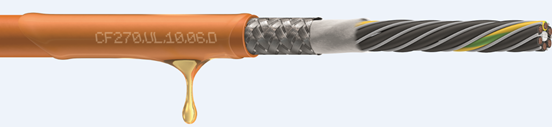

Oils can damage plastics and also the materials of a cable when used continuously in environments with oil contamination. For some applications, the oil resistance of the cables used is therefore essential. Without this feature, the cable used would not last long. There would be defects in the jacket and in the end the machine would come to a standstill if the cable failed.

Classification of chainflex® cables

The oil resistance of igus cables is particularly important for many applications and customers. Therefore, it is part of the chainflex classifications in our catalogue. Here, the customer can see how well or poorly each cable is suited for the respective area. The higher the number the better the cable in that area.

4 levels of oil resistance

The oil resistance of our cables is divided into 4 levels here:

No oil-resistance

Within a short time, the outer jacket of the cable is damaged and in some cases even completely destroyed. Cables without oil resistance are used in oil-free environments such as woodworking machines or high-bay warehouses.

Oil-resistant according to DIN EN 60811-2-1 and DIN EN 50363-4-1

The cable can withstand a short period of exposure to oils such as hydraulic oil without damage to the outer jacket. These types of cables are popular for use in environments where oil is present in smaller quantities.

Oil-resistant according to DIN EN 60811-2-1 and DIN EN 50363-10-2

The cables are heavily stressed by oils and do not show any significant degradation. The cables can therefore be used in machine tools, in which no organic oils are used.

Oil-resistant according to DIN EN 60811-2-1 and organic-oil resistant following VDMA 24568 with Plantocut 8 S-MB from DEA

These cables are resistant not only to synthetic oils but also to organic oils. The cables are suitable for machine tools, but also in many other environments where aggressive oils are used, e.g. in the aviation industry

Which cables are oil-resistant?

How do I find a cable with optimum oil resistance?

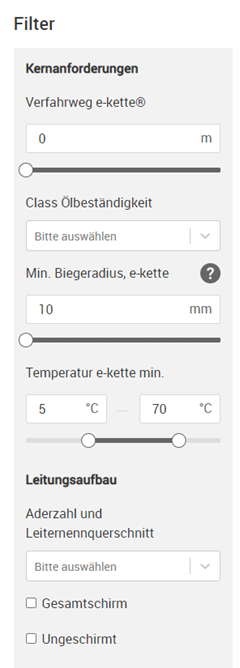

Our product portfolio includes a wide range of oil-resistant cables. These can be easily filtered out using the filter options in the respective cable categories.

If we look at the example of the control cables, this can be entered on the appropriate product page in the filter on the left-hand side. Here the search can be filtered according to the following main criteria:

Key requirements

- Travel

- Oil resistance class

- Min. bend radius

- e-chain temperature

- e-chain min.

Cable structure

- Number of cores and conductor nominal cross section

- Shielding

Material

- Jacket material

Electrical information

- Nominal voltage

Requirements

- Flame-retardant

- Silicone-free

- Halogen-free

- Cleanroom

- Coolant-resistant

- And many more

Do you have questions about the topic or need help selecting the right cable for your application? We look forward to hearing from you.