Maintenance-free knife edge rollers in the food industry

Marc Preinesberger | 3. May 2021

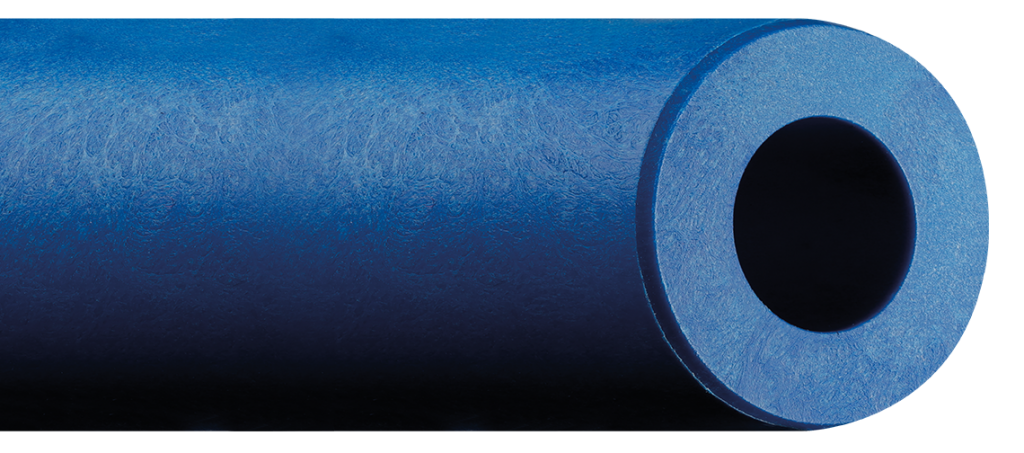

iglidur A250 is also called “The fast runner that withstands up to 90°C”. But what makes the material so interesting for the food industry besides its operating speed and temperature resistance? First of all, A250 is FDA and EU10/2011 compliant and optically detectable. They can therefore be used without any problems where food is processed. Furthermore, maintenance-free knife edge rollers can be implemented in the food industry with iglidur A250 knife edge rollers.

No lubrication necessary

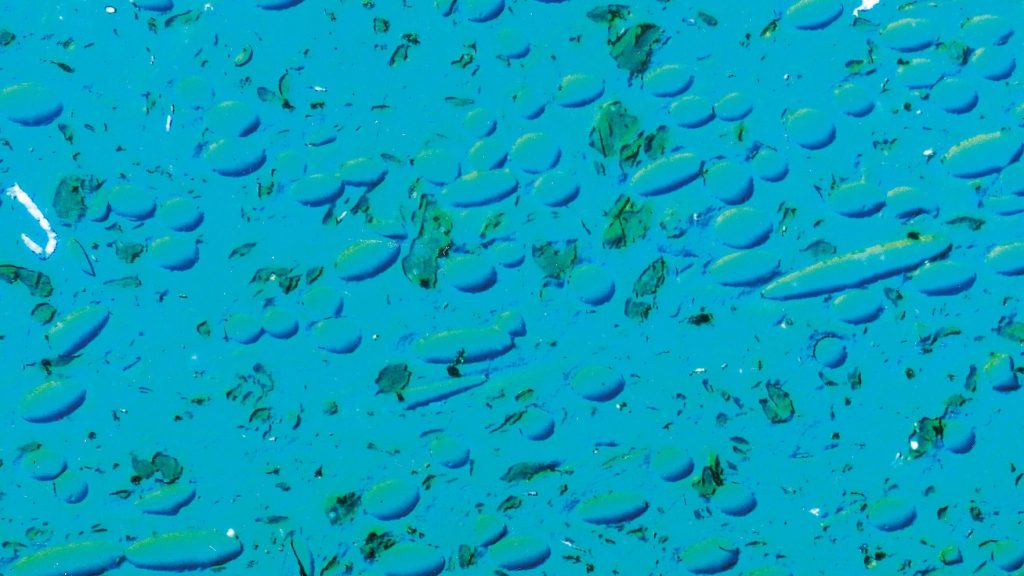

iglidur knife edge rollers do not require any additional lubricants. Regular maintenance is therefore not necessary and machine downtime due to insufficient lubrication does not even occur. The reason is the self-lubricating effect. Millions of solid lubricants are embedded in small chambers in the material. So tiny amounts of the lubricant are released to lubricate the bearing point. Nice side effect: the drive power of the iglidur knife edge rollers is additionally reduced.

Long service life due to extensive testing

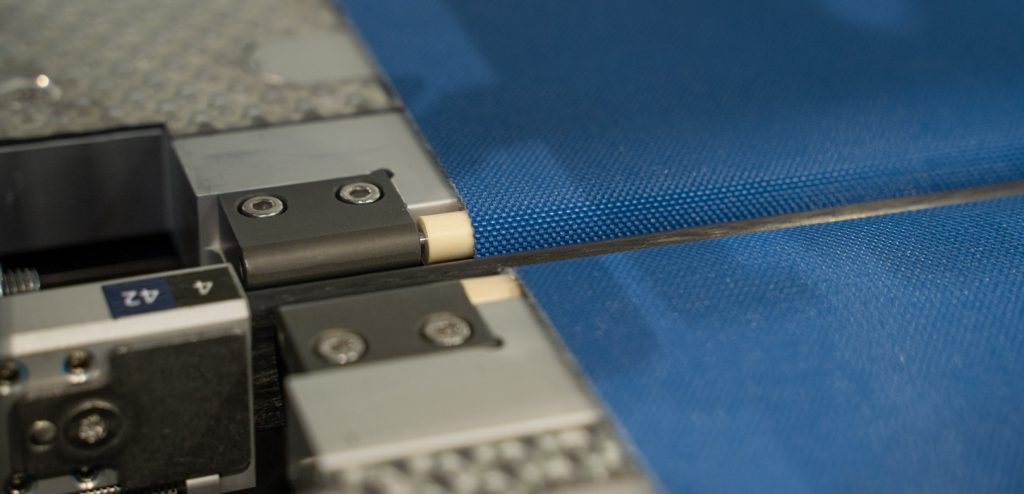

In the igus test laboratory our products and iglidur materials are tested for their stress, wear and friction properties. The use under certain temperatures, high loads and speed is also tested here. With around 50 test facilities, more than 300 concurrent tests are carried out here. Therefore, we can precisely determine the service life of our products and also carry out individual tests for our customers.

Closely guided

It is no secret that tipping beverage containers in a packaging line can cause bursts and lead to a lot of cleaning work. The situation is similar with food containing jam, such as baked goods. In the worst case, cleaning leads to a stoppage of the plant’s equipment and to production losses.

With the use of iglidur knife edge rollers, conveyor belts and modular chains can be guided very closely. Their small diameter makes it possible to keep the gap between two conveyor belts small. This prevents beverage containers from tipping over during transport from one conveyor belt to the other and from food getting caught between the conveyors.

iglidur A250 knife edge rollers are available in various dimensions in the igus online shop.

You can find more information about our different iglidur knife edge rollers here.