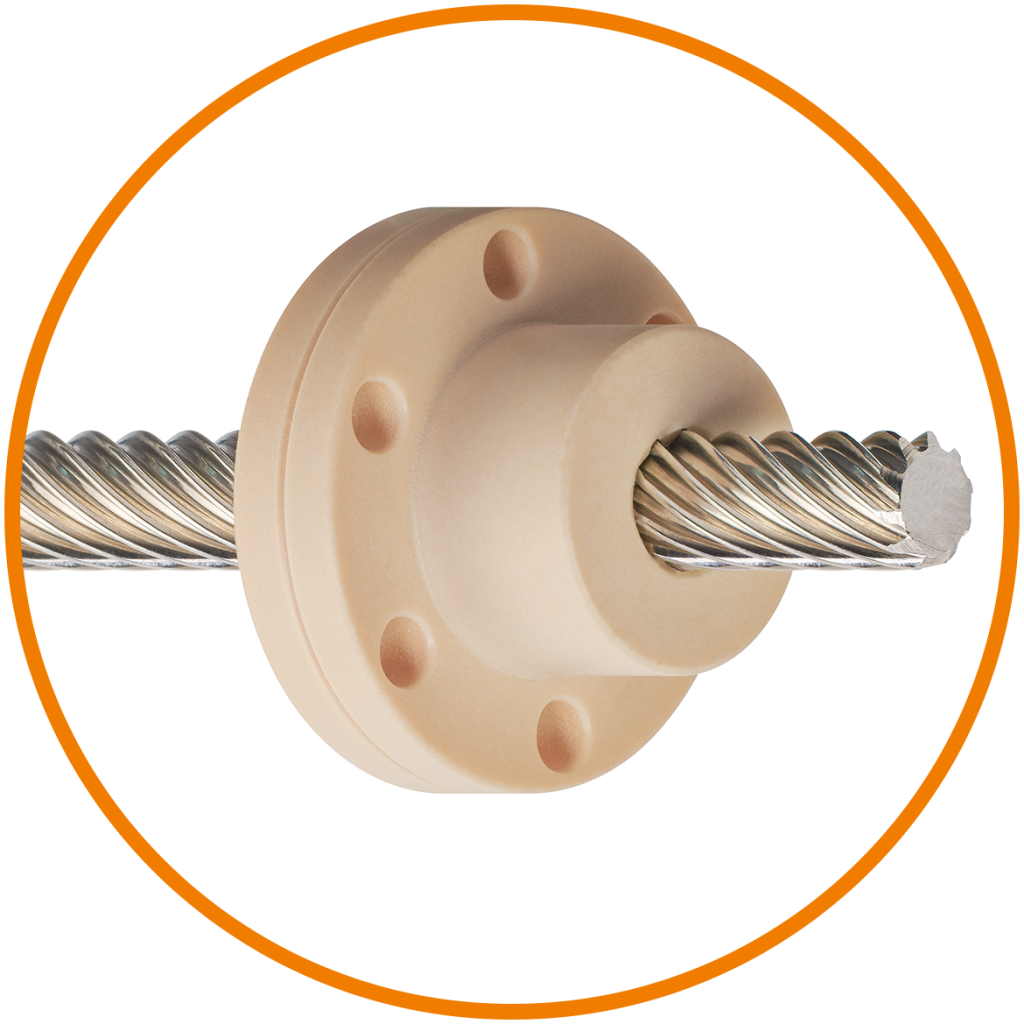

Lubricating polymer lead screws

igu-blog-adm | 18. January 2021

Can I lubricate my polymer lead screw?

Is lubrication necessary for igus® polymers? Does external lubrication offer me any advantages and would it be necessary?

It is no secret that igus® is an advocate of non-lubrication of bearings. Simply put, lubrication is not required for igus® products. But that doesn’t stop customers from asking the recurring question: “Can I use WD-40 or another lubricant to grease my bearing?”

Many people think that greasing some products is essential to ensure that they do not seize up and can continue a smooth movement. However, it is easy to forget that lubrication is not a prerequisite for all products.

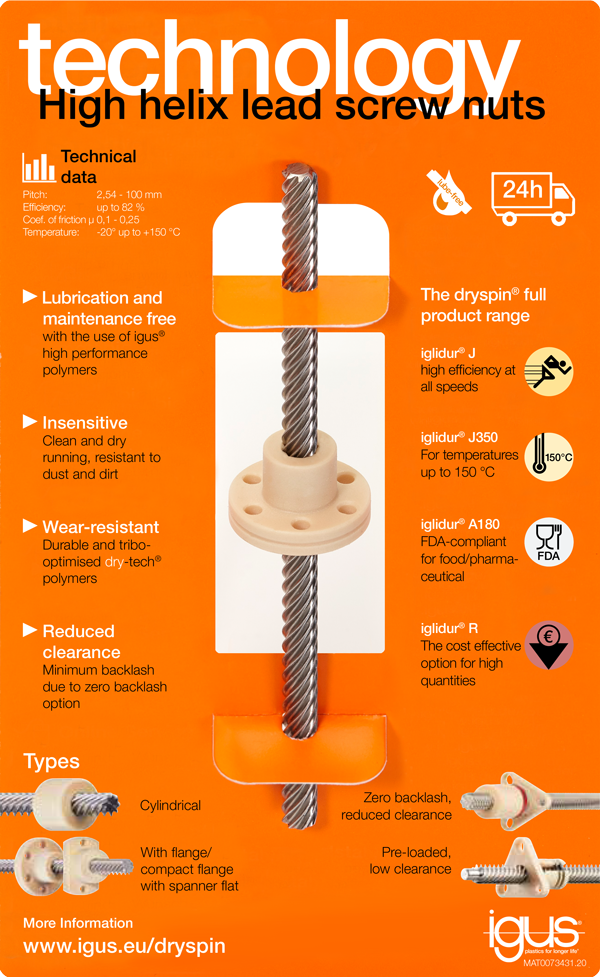

This article is intended to emphasise once again that absolutely no lubrication is required for our igus® lead screw nuts. But it should also explain why you can still use WD-40 or OKS400, but don’t have to. We will use the two brands mentioned as examples in this article, but of course there are other forms and brands of lubrication or lubricants.

Let’s take a closer look at the WD-40 lubricant

If you take a closer look at the composition of WD-40, it quickly becomes clear that it is not necessarily the best lubrication to keep the bearing lubricated without affecting friction. This is due to the fact that WD-40 is called a “penetrating oil”.

In detail, this means that the lubrication can penetrate cavities, mix with dirt and dust particles and bring them to the surface. It is also not suitable as a long-term option due to its thin consistency.

Does the use of WD-40 or similar lubricants affect the performance of igus® polymer lead screws?

To get the exact answers to such questions, it is essential that we consult chemical tables to make the effects of WD-40 on the iglidur® materials very clear. A 100% resistance of the iglidur® materials depending on the type of contamination and the lubricant cannot be assured.

Also, at this point, we need to consider durability and the wear effect as two separate issues. As a rule, our materials are resistant to such oil-based lubricants, but this does not mean that they do not affect the lead screw nut.

And why does the igus polymer lead screw not need to be lubricated?

Our lead screw systems are developed for maintenance-free dry operation. Basically, you should not compare a lubricated lead screw system one-to-one with a dry-operating system. Due to the external lubrication, the coefficient of friction is lower compared to a dry-operating lead screw system. However, the lubricant also causes a high maintenance effort and additional costs that are often not accounted for.

In justified cases, however, external lubrication of iglidur® lead screw nuts can be considered to reduce the coefficient of friction or to increase the speeds without noise generation. However, you should always consult one of our experts to find out whether this really makes sense for your application. The rule of thumb is:

In an abrasive environment, do not lubricate -> “emery paste”.

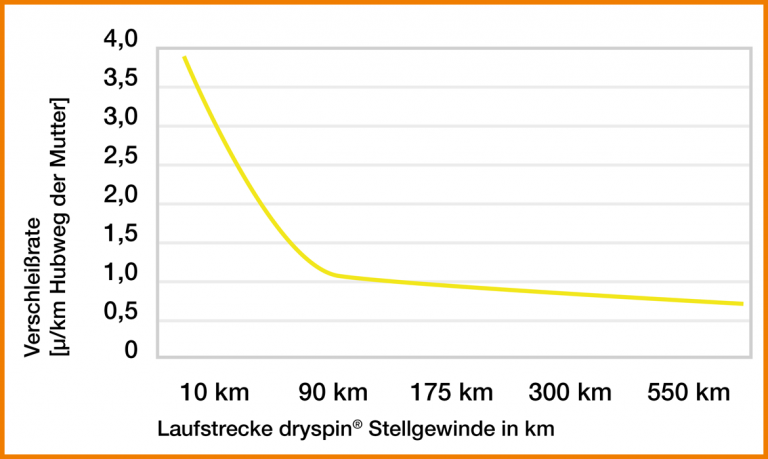

Another lubrication option is initial lubrication. This is conceivable in particular for better run-in behaviour. After the lubricant has been depleted, wear occurs in an almost linear pattern:

Many manufacturers declare their products to be “maintenance-free”. This usually means that the respective bearings or lead screw nuts are delivered with initial lubrication. But maintenance of any kind is not necessary only as long as this lubrication is intact.

iglidur® polymers, in contrast, do not have a lubricating film and no reservoir of grease that is eventually used up. The homogeneous structure of the lead screw nut material ensures that wear is mostly linear without any surprises or maintenance intervals that have to be adhered to. Our materials are also characterised by their other special specifications: their special composition makes them extremely wear-resistant and resilient. Due to the self-lubricating effect, the lead screw nuts are 100% dry-operating and maintenance-free. Particles such as dust and fibres can thus adhere to the lead screw drives much more poorly. In dirty environments, this greatly increases service life over that of conventional, lubricated materials. Regular relubrication of the lead screw drive is not necessary due to the incorporated solid lubricants.

In conclusion, dryspin® lead screw nuts are resistant to most commercially available lubricants. However, it could well lead to increased or reduced wear. If you really want to relubricate externally, lithium-saponified, mineral oil-based greases are the best option.

Use in various industries

The above-mentioned advantages make it possible for dryspin lead screw drives to also be used in special industries. In medicine or pharmaceutical technology, for example, it is mandatory that the installed products are absolutely clean, hygienic and very easy to clean. In very dirty environments, on the other hand, it is important that no dirt particles stick to the lead screw nut or in the lead screw. This has a negative influence on the wear and running behaviour. Here you will find all application areas of our dryspin lead screw drives.

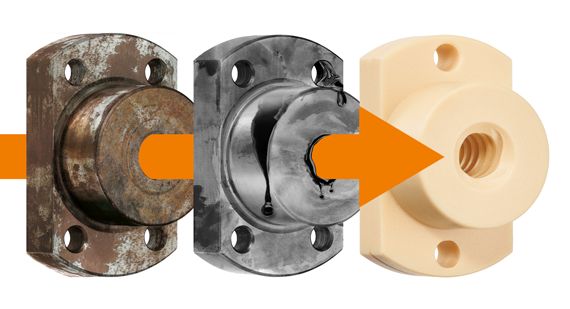

Our polymer lead screw nuts compared to the metal solution

Metal lead screw systems require regular lubrication. Without suitable lubrication, they start to corrode in a short time. To prevent this, adequate downtime for maintenance intervals is indispensable. The absolute freedom from lubrication and maintenance of our polymer lead screw nuts also solves the problem here and offers a perfect alternative to lead screw drives made of metal. Thus, replacing the lead screw drives results in Tech up and Cost down.

Do you have any questions?

Send us your contact request here

Our experts will find a solution for you.