Lead screw support

Zoe Moser | 4. December 2020

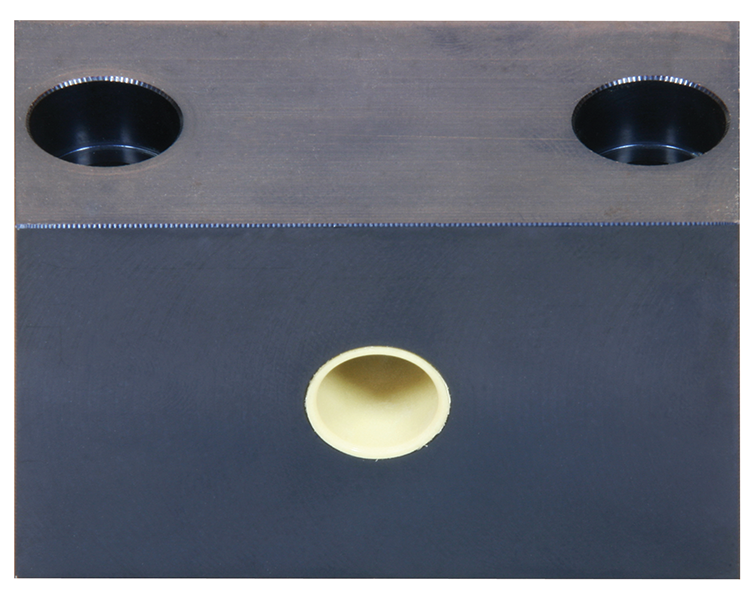

Corrosion-resistant lead screw support

Our dryspin® SLS lead screw support blocks

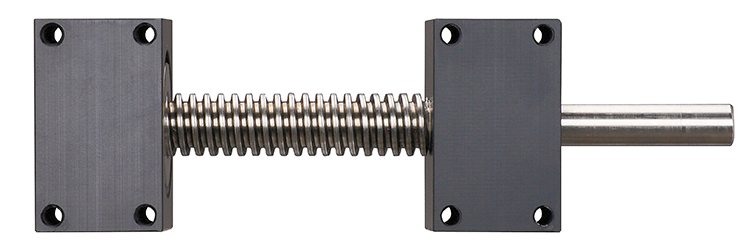

Our lead screw support blocks are available in thread sizes of 6-24 mm. Choice of mounting: plain bearings or, with higher dynamics, ball bearings (BB). All lead screw support blocks, like the matching lead screw clamp rings, are supplied in hard anodised aluminium.

FL: fixed bearings with anodised clamping ring with right-hand threads and lubrication-free iglidur® plain bearings

LL: Floating bearings with lubrication-free iglidur® plain bearings

LH: optional: left-hand threads, only TR10x2, TR10x3, TR18x4, and TR24x5

Advantages:

► Lubrication-free and maintenance-free

► Practical housing for lead screw support

► Mounting holes for your design

► Prepared for connection of accessories such as

position indicators and manual clamps

► Available for lead screws of diameters 6-20mm

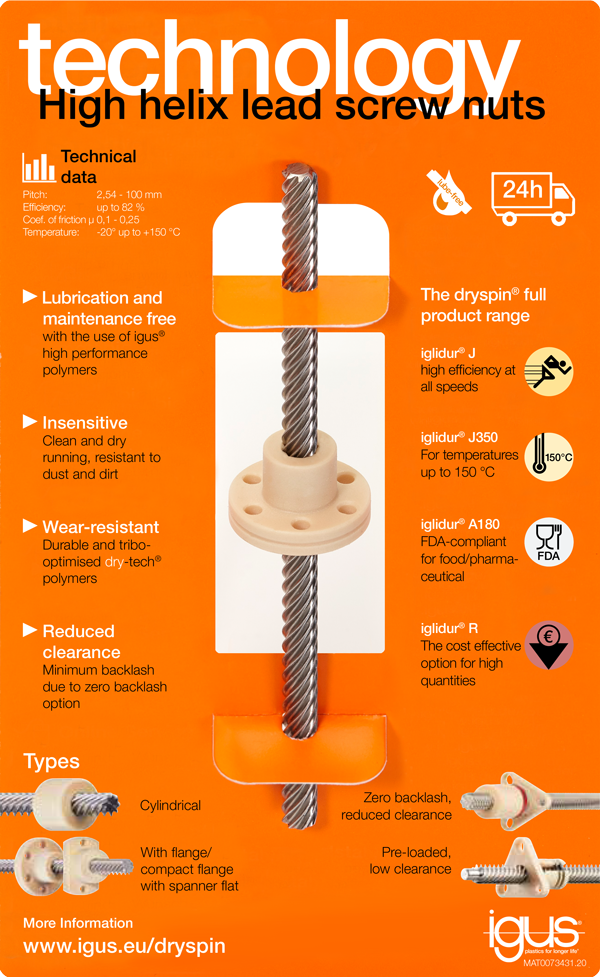

► Trapezoidal thread and high helix thread versions

Why are there different versions of lead screw support?

The basic requirement for bearing arrangement is that it fulfils the principle of clarity. The bearing must also ensure defined force flow control. If it does, the bearing is considered statically determined. There are various bearing options, such as the fixed floating bearing and the double-sided floating bearing.

The difference between the fixed floating bearing and the double-sided floating bearing

Fixed floating bearing:

The fixed bearing clearly positions the shaft in an axial direction. The fixed bearing must therefore absorb both radial and axial forces and guide them into the surrounding structure. This can basically be done by a single bearing. The floating bearing corrects parallelism errors minimally and offers thermal expansion capability, which means that the cable is not stressed.

Advantages of the fixed floating bearing

► No axial clearance

► Non-critical shaft expansion (due to such factors as temperature)

► Suitable for changing axial loads

► Clarity of forces applied

Double-sided floating bearing:

In a double-sided floating bearing, the lead screw is not clearly fixed in the axial direction. This means that without stressing the bearing, mechanical or thermal differences in length can be absorbed, but the lead screw is not protected against drifting. This is especially important to consider for positioning applications!

Advantages of double-sided floating bearings:

► Cost-effective

► Low design cost

► Non-critical shaft expansion (due to such factors such factors as temperature) in the area of clearance

Disadvantages:

► Not clearly fixed in the axial direction

► Not suited to changing axial loads

► Only if axial clearance does not impair function

Lead screw support versions

Fixed-bearing (FL) version

Depending on thread dimensions, this version has the clamping ring clamped into the lead screw itself or to the lead screw’s outer diameter. For high helix lead screws, it is always the outer diameter that it is clamped to. To the online shop

► Note: for your application, you can also choose a lead screw support block that uses the d1 measurement for clamping onto the turned machined end.

Floating bearing (FL):

depending on the lead screw’s dimensions, a machined end must be turned to the value d1. You can see the dimensions this applies to below. The floating bearing block merely supports the lead screw. This type does not prevent the lead screw from drifting! To the online shop

Ball bearing type (BB):

this bearing block should always be used in highly dynamic applications such as those in which a motor is used. To the online shop

Design tip for lead screw end machining

| Part number | d1 mm |

|---|---|

| SLS-16×2-LL | 12 |

| SLS-16-LL | 12 |

| SLS-18-LL | 12 |

| SLS-18x8P4-LL | 12 |

| SLS-18-LL | 12 |

| SLS-18-LL | 12 |

| SLS-20-LL | 12 |

| SLS-24-LL | 14 |

| SLS-S16-LL | 12 |

| SLS-S18-LL | 12 |

| SLS-S20-LL | 12 |

The dryspin® configurator enables you to quickly find the right lead screw and machine the ends individually from both sides. The application generates a dimensioned drawing of the configuration for you. You can then order the lead screw or request further information.

Do you have any questions?

Send us your contact request here

Our experts will find a solution for you.