Lead screw nut material

Zoe Moser | 26. November 2020

The special properties of our lead screw nut materials

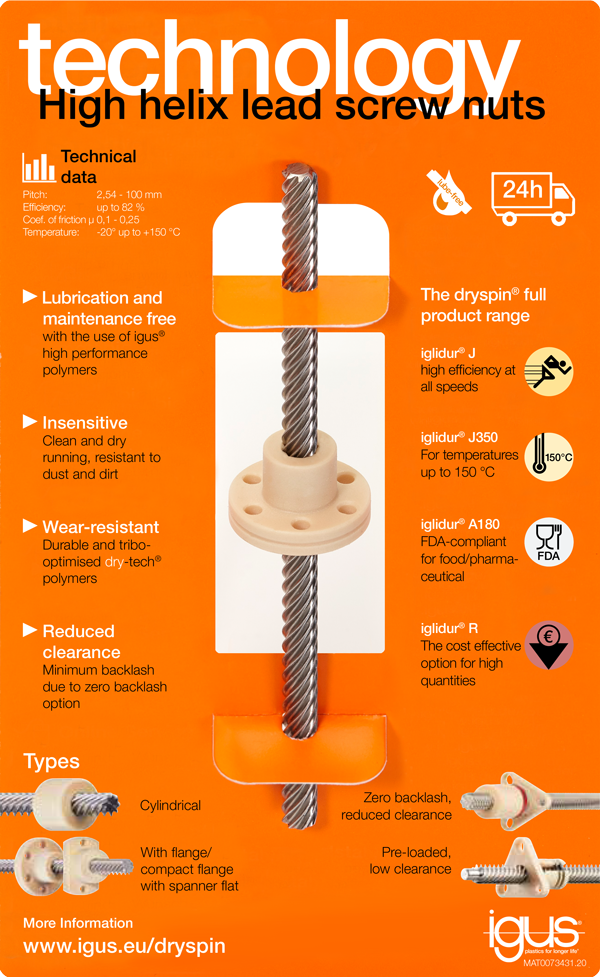

dryspin® lead screw technology offers the right lead screw nut material for any technical requirement. But what exactly are its advantages? And how do I find the right lead screw nut material for my application?

Lubrication-free, maintenance-free drylin® lead screw drives are the perfect alternative to conventional metal lead screw systems. All drylin® lead screw nuts are made of high-performance iglidur® polymers. The tribologically optimised plastics are characterised by their special properties: their special composition makes them extremely wear-resistant, robust and self-lubricating.

Self-lubrication reduces maintenance to a minimum. The incorporated solid lubricants eliminate the need for regular lead screw drive re-lubrication. Dry operation gives particles such as dust and fibres much less purchase. In dirty environments, this greatly increases service life over that of conventional, lubricated materials.

Overview of lead screw nut materials

iglidur® J350

► For high temperatures

► Good coefficient of friction at medium load

iglidur® R

► Low wear at high loads

► Low moisture absorption

► Vibration dampening

iglidur® A180

FDA-compliant for the food and pharmaceutical industries

► FDA-compliant

► For food contact

iglidur® J200

Best counterpart for aluminium

► Low coefficient of friction and wear

► Long service life

Material properties

Let’s take a closer look at the material properties Each material has special strengths. Lead screw nut materials such as iglidur® A180 and iglidur® J are suitable for applications in damp and wet environments. What is characteristic of these materials is that they absorb very little moisture. Other materials, on the other hand, can be used in temperature ranges between -20°C and +90°C. In addition, there are versions that withstand extreme temperatures (up to +150°C). Our overview highlights what each material’s greatest strength is:

General properties

| Unit | J | J350 | R | A180 | E7 | J200 | ||||||

| Density | [g/cm3] | 1,49 | 1,44 | 1,39 | 1,46 | 1,05 | 1,72 | |||||

| Colour | yellow | yellow | red | white | dark grey | matt grey | ||||||

| Max. moisture absorption at +23°C and 50% relative humidity | [% weight] | 0,30 | 0,30 | 0,20 | 0,20 | 0,1 | 0,2 | |||||

| Max. total moisture absorption | [% weight] | 1,30 | 1,60 | 1,10 | 1,30 | 0,1 | 0,7 | |||||

| pv value, max. (dry) | [MPa·m/s] | 0,34 | 0,45 | 0,27 | 0,31 | 0,08 | 0,30 |

Mechanical properties

| Mechanical properties | Unit | J | J350 | R | A180 | E7 | J200 | |||||

| Permissible surface pressure in the thread at +20°C | [MPa] | 4,0 | 3,0 | 2,0 | 3,5 | 0,5 | 2,0 | |||||

| Shore D hardness | 74 | 80 | 77 | 76 | 61 | 70 |

Physical and thermal properties

| Unit | J | J350 | R | A180 | E7 | J200 | ||||||

| Max. long-term application temperature | [°C] | +90 | +150 | +90 | +90 | +70 | +90 | |||||

| Max. short-term application temperature | [°C] | +120 | +150 | +90 | +90 | +70 | +90 | |||||

| Min. application temperature | [°C] | -20 | -20 | -20 | -20 | -20 | -20 | |||||

| Thermal conductivity | [W/m · K] | 0,25 | 0,24 | 0,25 | 0,25 | 0,25 | 0,24 | |||||

| Coefficient of thermal expansion at +23 °C | [K–1 · 105] | 10 | 7 | 11 | 11 | 11 | 8 |

Electrical properties

| Unit | J | J350 | R | A180 | E7 | J200 | ||||||

| Specific contact resistance | [Ωcm] | > 1013 | > 1013 | > 1012 | > 1012 | > 109 | > 108 | |||||

| Max. short-term application temperature | [Ω] | > 1012 | > 1010 | > 1012 | > 1011 | > 109 | > 108 |

Help in selecting the right material

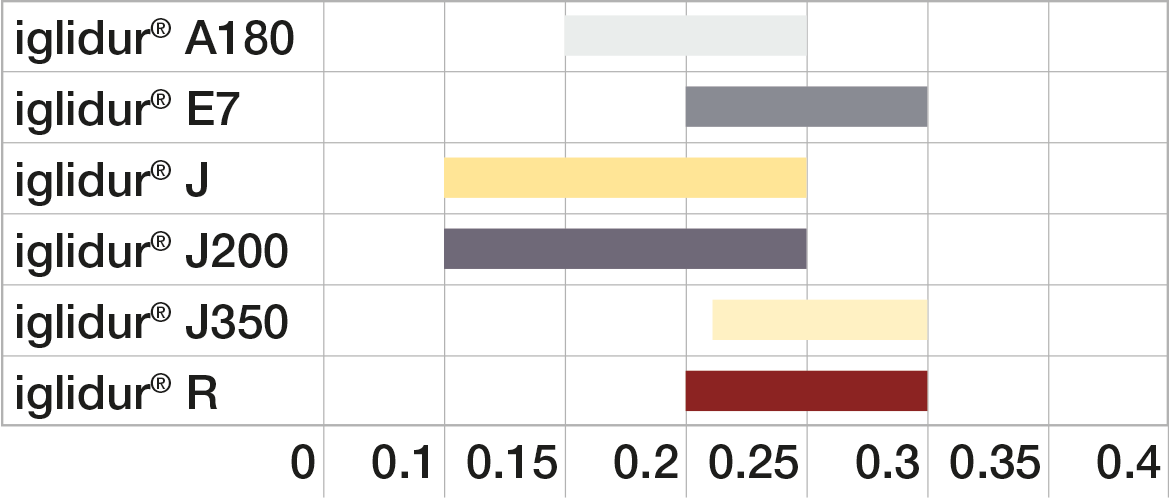

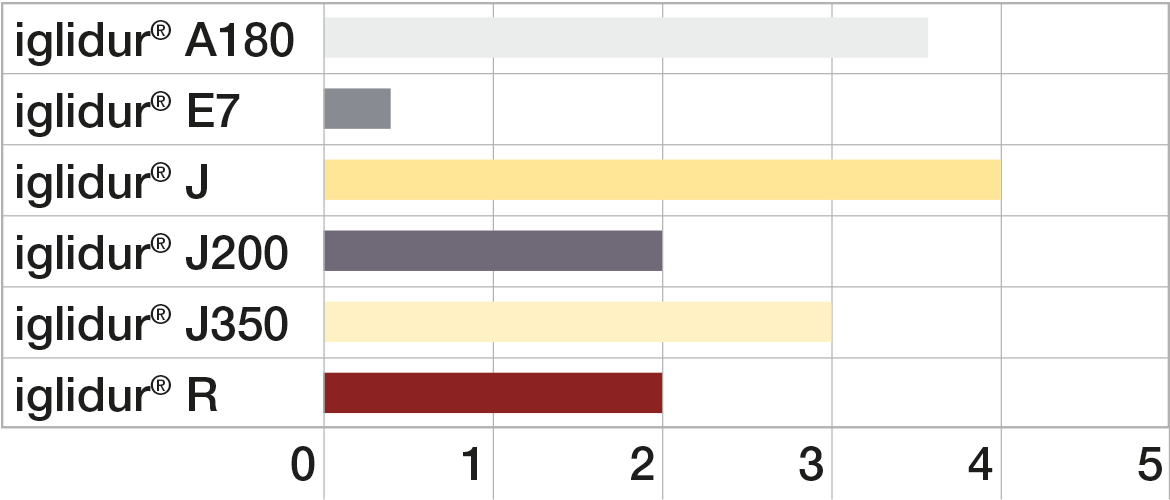

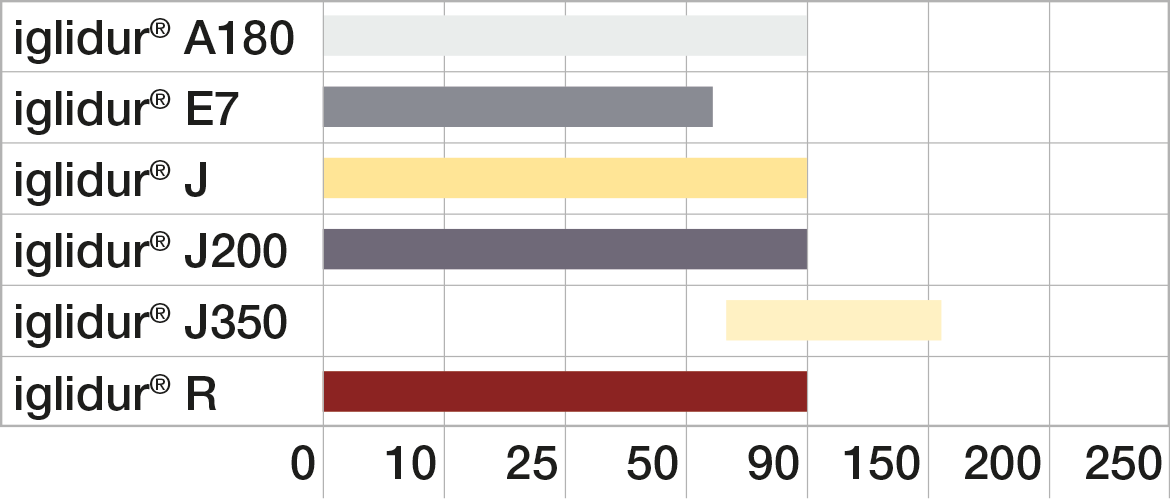

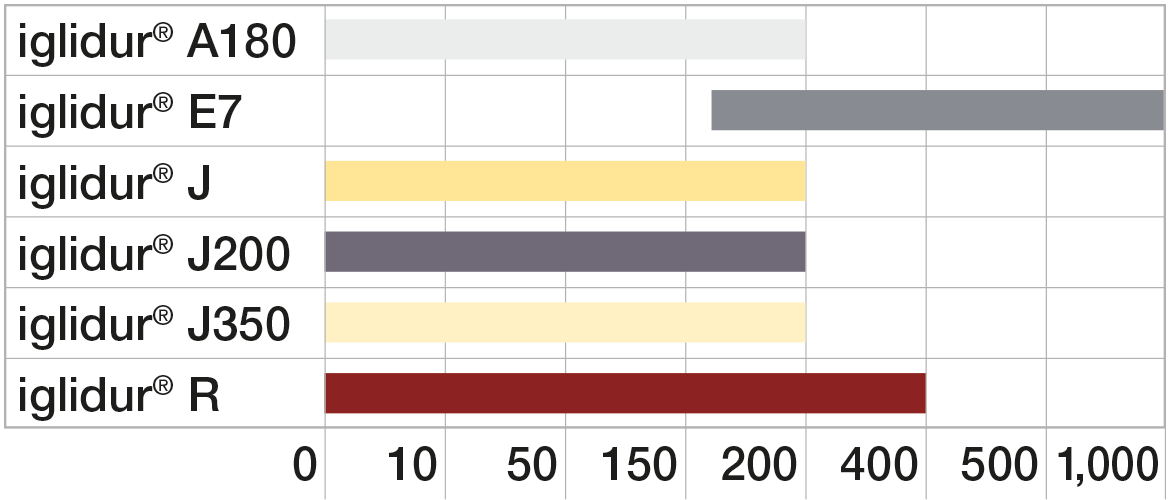

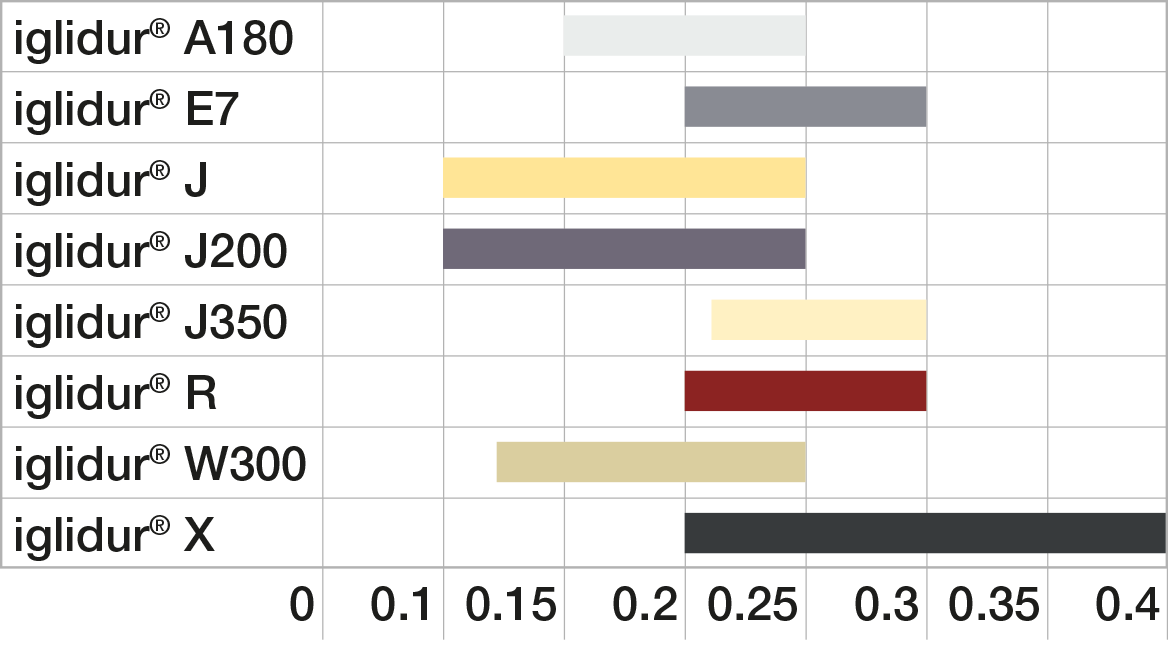

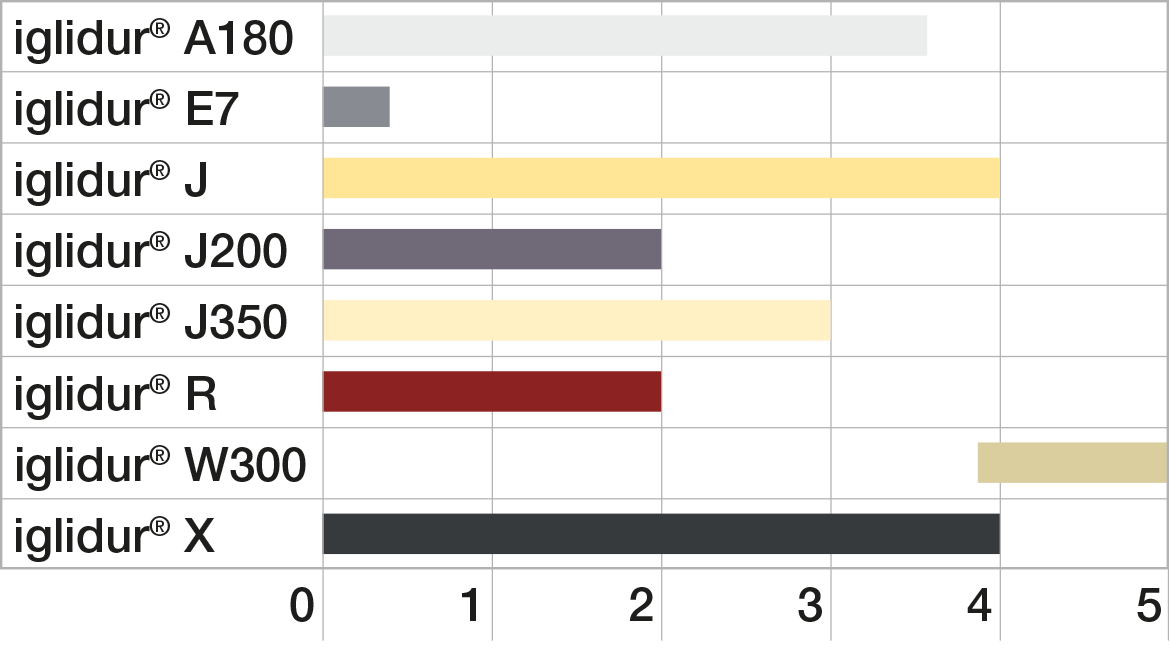

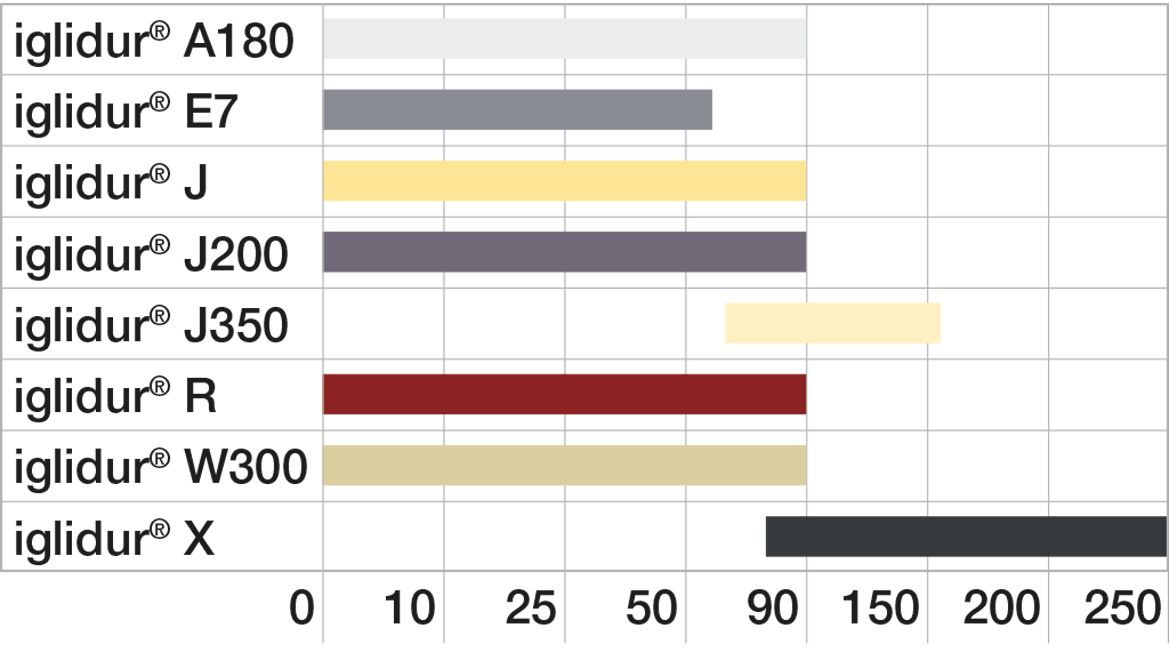

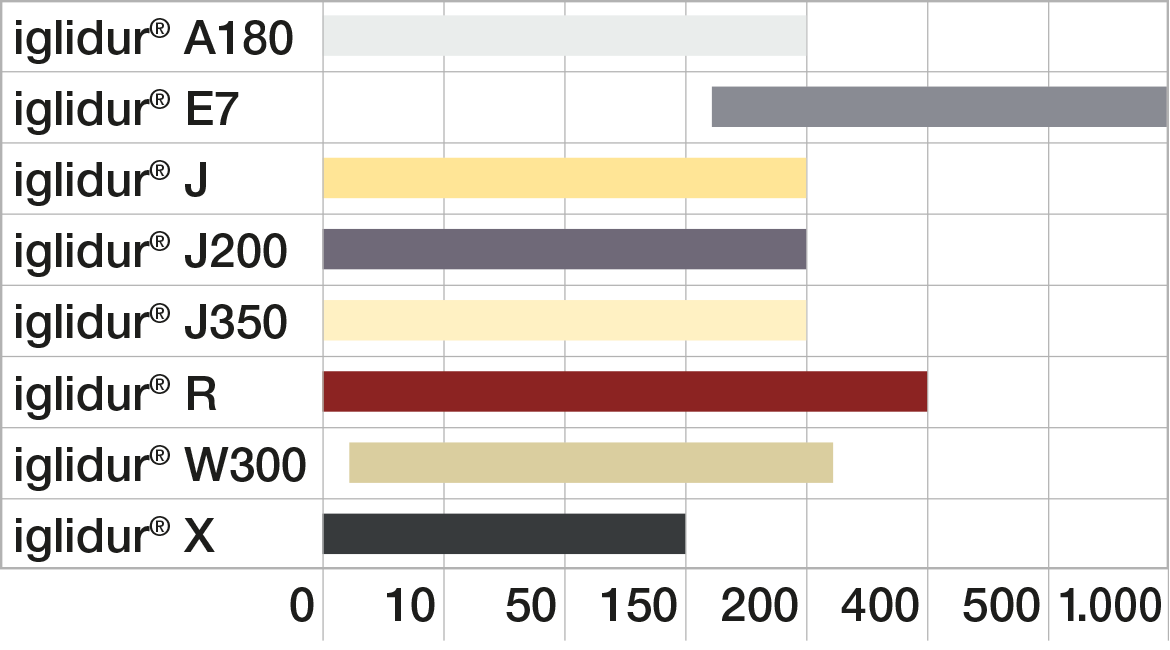

To help you find the right material for your application, we have created a few more graphs. Here, we compare speeds, temperatures, coefficient of friction and surface pressures. The graphs are subdivided into high helix threads and trapezoidal threads. If you have questions or would like personal consultation, you can send us your contact request here.

High helix lead screw

Coefficient of friction [µ] | Surface pressure in the thread [MPa] | |

Temperature [°C] | Speed [rpm] |

Trapezoidal lead screw

Coefficient of friction [µ] | Surface pressure in the thread [MPa] | |

Temperature [°C] | Speed [rpm] |

Want to test lead screw technology?

Request a free dryspin® sample here.

All information at a glance!

Do you need more information?

Have a look at our home page!

All information about lead screw technology