Knowledge of lead screw drive

Zoe Moser | 7. September 2022

Five things I should know about dryspin® lead screw technology – part 1

In today’s rapidly changing world, we are constantly faced with new challenges. Be it the search for resource-saving and energy-efficient solutions or increasing the efficiency of small components in large machines. There are also increased supply bottlenecks and climate change.

In order to cope with rapid change, companies regularly introduce numerous innovations. The igus GmbH, for example, showed its latest innovation in spring: the igus bike, a fully equipped bicycle made from recycled plastic. But not everything has to change all the time. Some things remain constant and yet important, e.g. lead screw technology. But that doesn’t mean that innovations aren’t taking place here too. The demands and requirements placed on a lead screw drive are constantly increasing. Integrated lead screw technology must meet ever higher performance requirements and be as cost-effective as possible. New technologies are therefore needed that improve processes and increase the service life of a lead screw drive. In addition, every industry has specific requirements for a lead screw drive that must be met. And as trivial as a lead screw drive may seem at first glance, it certainly isn’t. The new requirement profiles often present many challenges for designers and manufacturers.

But let’s start with the basics of lead screw technology first. The following question should be addressed in advance:

1. What does lead screw technology mean and what can I imagine it to mean?

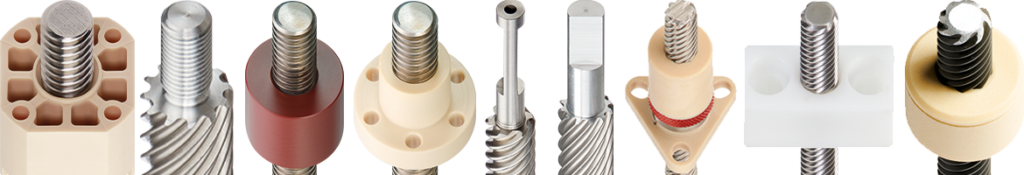

The lead screw technology is a sub-area of drive technology and, roughly speaking, describes the repetitive conversion of a rotating movement into a translational movement within regular cycles. A lead screw and the appropriate lead screw nut are always required for a complete lead screw drive. Lead screw nuts can be designed as a classic cylindrical nut or as a flange lead screw nut – special shapes such as spanner flat lead screw nuts up to complete custom geometries are possible. Lead screws are offered on the market unmachined, with custom machined ends, or as reverse lead screws. Both lead screws and lead screw nuts have a profiled notch which runs continuously in a helical manner along the respective cylindrical contour. This notch is also referred to as a thread pitch. Lead screw drives can have one or more thread pitches. The lead screw nut has the negative profile and the lead screw has a positive notch. The lead screw is also referred to as a male thread, and the lead screw nut has a female thread. Lead screw technology uses either lead screw nuts made from high-performance plastics, metals such as bronze and gunmetal, or recirculating ball screw nuts made of steel. Lead screws are available in steel, stainless steel or aluminium.

So much about the general facts about lead screw technology. In this article, we would like to take a closer look at our dryspin® lead screw technology: What does igus® offer me as a customer and what can I expect from the dryspin® lead screw technology from igus®? Let’s start in general terms.

2. Which products does the lead screw technology at igus® actually include?

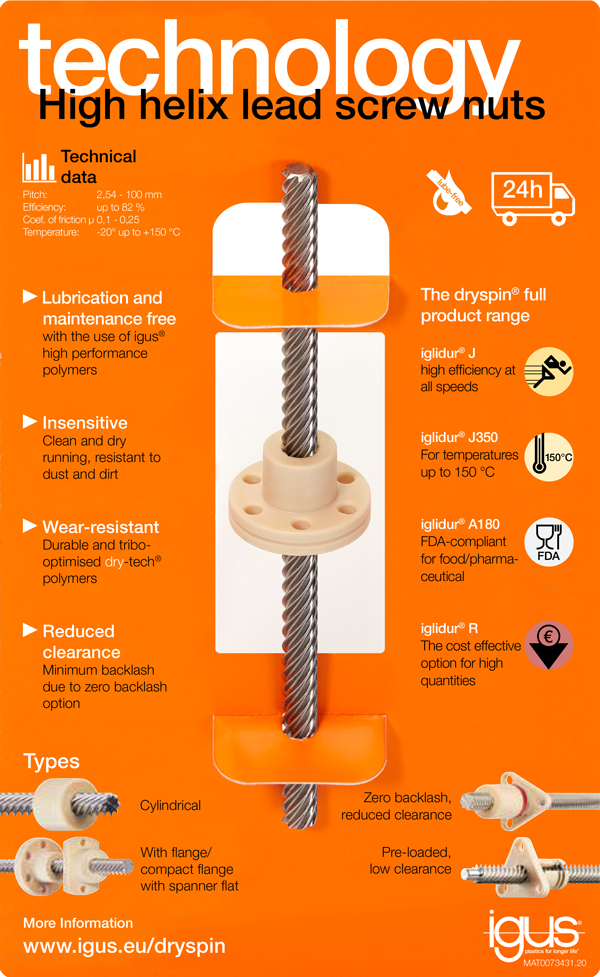

The dryspin® product range covers a large part of possible thread dimensions. The range includes both variants with low pitches, e.g. trapezoidal lead screws, metric lead screws or imperial ACME lead screws, as well as variants with high pitches, such as the specially developed dryspin® high helix lead screws. The matching lead screw nuts are all made from specially developed, lubrication-free and maintenance-free iglidur® high-performance plastics. With available diameters of 3mm to 50mm and pitches of 0.5mm to 100mm, dryspin® lead screw drives are suitable for almost all applications. The available lead screw materials, such as steel, stainless steel and aluminium, and the seven different high-performance plastics for lead screw nuts, successfully cover a wide range of customer requirements.

But with such a selection of different thread dimensions and thread geometries on the market, how are you supposed to decide and find the right size? This is often not easy, as every application is individual: wide operating temperature ranges, load cycles in vertical applications, permanent static loads, dust and dirt, and much more. There are many reasons and individual requirements for using lead screw drives. So why did igus® take the trouble to bring its own thread geometry onto the market when there are already so many standard geometries that have been proven over the years? We’ll find that out with the next question.

3. What exactly distinguishes dryspin® lead screw technology from conventional lead screw drives?

The question is fairly easy to answer. Basically, you need to know that dryspin® thread geometry is based on the sliding thread principle. As already mentioned above, the counter partner of the lead screw at igus® is always made of lubrication-free and maintenance-free high-performance plastics. These iglidur® high-performance polymers were developed by igus® for the best tribological specifications. Tribology is the study of wear, friction and lubrication. As a result, igus® lead screw technology guarantees up to 30% longer service life and up to 82% higher efficiency compared to conventional lead screw drives.

But dryspin® lead screw drives distinguish themselves not only by their good service life and high efficiency. The dryspin® lead screw technology developed and patented in 2013 also has – in addition to the general points mentioned above, such as freedom from lubrication and maintenance – further advantages, e.g. in terms of better operating characteristics and low wear. In particular, the asymmetry of the dryspin® thread makes a big difference compared to conventional threads. The dryspin® thread is optimised for the use of plastic nuts and, thanks to a larger proportion of wear material in the thread pitch, offers a longer service life in dry operation compared to comparable trapezoidal threads. In addition, rounded tooth flanks allow quieter and vibration-free operation. As a result, higher speeds, or travel speeds, become possible. Were all these advantages not enough, or do you still lack detailed explanations? No problem! All information about dryspin® benefits can be found clearly summarised on our home page.

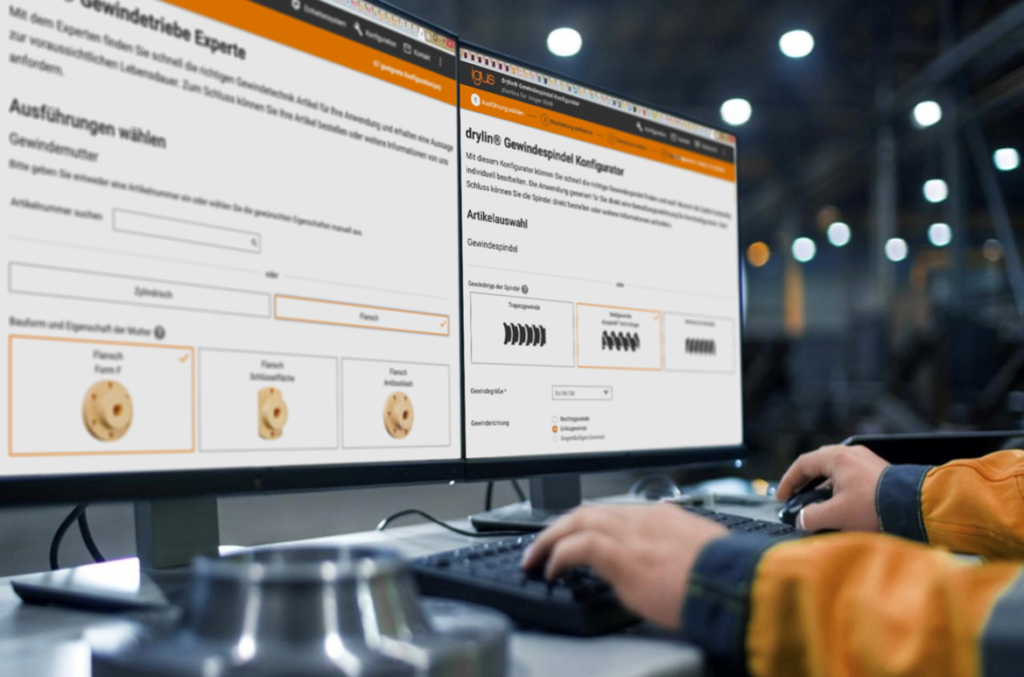

4. Can I also calculate and configure my lead screw drive individually and get an overview of my options?

The question can quickly be answered with a “Yes!”. Another igus® USP is exceptional predictability of all our lead screw drives incl. specification of required torque and an expected number of cycles. This prediction is free of charge for a customer and can be used without registration. This expert offers guidance on selecting the ideal lead screw drive.

This expert offers guidance on selecting the ideal lead screw drive. The aim of igus® is to offer the customer a possibility to find a functioning and also the most cost-effective solution independently. This tool calculates suitable combinations and shows the expected service life and the required drive force of the lead screw drive. If this tool does not produce the desired result, the igus® sales team is always available to answer any questions.

But the expert is not the only tool in dryspin® lead screw technology. There is also the configurator for lead screws, which can also be found on our website and can be used free of charge. The tool offers the option of configuring a special lead screw according to individual requirements. As a result, the customer immediately receives a price calculation and the associated PDF dimension drawing. If a configuration cannot be displayed, or if a lead screw nut is also required, the igus® sales team is also available here. In the final step, both tools offer the option of ordering directly online, making classic enquiries or requesting further information.

Let’s move on to another topic: the lubrication of the lead screw nuts. Both types of lead screw drives, with external lubrication and dry-operating systems, have a reason to exist. This also applies to ball-guided and sliding systems.

5. When using dry-operating dryspin® lead screw drives, the question sometimes comes up: Can I lubricate my plastic thread?

In general, the question cannot be answered directly in this way. We have written a separate and detailed article about this. Discussed here are topics such as which commercially available lubricant would be suitable, the effects this can have, and why external lubrication is not needed for igus® polymers. Feel free to take a look and learn the details about the lubrication of the lead screw nuts.

Test first?

Request a free dryspin sample here.

All information at a glance!

Do you have any questions?

Send us your contact request here

Our experts will help find a solution for you.

Do you need more information?

Visit our home page!

All information about lead screw technology