What is Selective Laser Sintering?

Selective Laser Sintering(SLS) is one of the powder-based additive manufacturing technologies. Physical plastic components are manufactured on the basis of CAD data by means of the energy input of a laser beam. The plastic in powder form is used as the starting material.

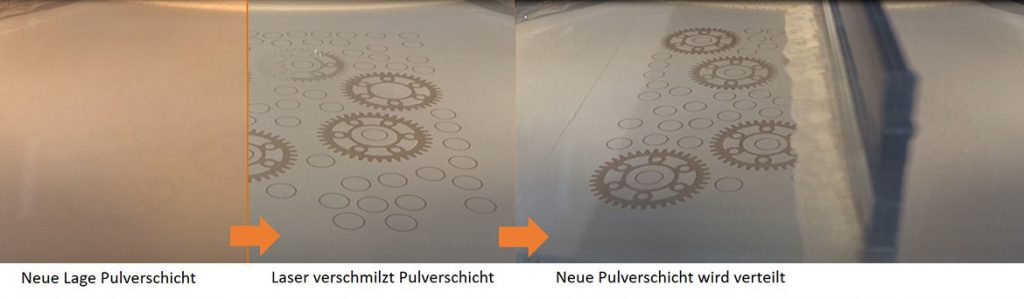

The laser sintering process is divided into 3 recurring steps:

– Application of the powder layer

– Adjustment of the temperature

– Exposure of the current layer

The powder is applied in a thin layer (typically 0.1 mm) above a fabrication platform in the build chamber of the printer and heated to just below the melting temperature.

The powder needs to have very good particle size distribution, if possible in the range of 10 to 100 µm. The powder must have sufficient flowability to ensure that the loose powder particles are packed together very tightly.

The laser beam melts the current cross sections (of the respective components) that are positioned in this layer. When the thin powder layer is exposed to the laser beam, it fuses with the layer underneath. Once a layer has been exposed, the fabrication platform is lowered and the next layer of powder is applied.

In the next step, the fabrication platform in the build chamber is lowered further and the powder bed, consisting of the already exposed parts and loose powder that functions as a support, descends so that further layers can gradually be added on top. In this way, the entire build chamber is filled additively from top to bottom at a speed of approximately 10 mm/h and several hundred up to a thousand small to medium sized parts of the component being built are fabricated.

After completion of the fabrication job, it has to be allowed to cool down. Cooling lasts approximately as long as the fabrication time. The build chamber container is then removed and carefully emptied in an unpacking station. The excess powder that has not been melted by means of the laser is removed and can be used again for the next printing process (recycling rates of approximately 10 to 50% are usual for laser sintering and can vary depending on the material used).

The cooled components are completely cleaned of excess powder and, depending on the requirements regarding the surface, are subjected to further treatment. Glass bead blasting is a standard cleaning method.

The rough surface structure, which is a result of the process, can be improved by means of post-processing methods. Established methods are mechanical abrasion involving slide grinding with grinding devices (also known as barrel finishing), as well as chemical smoothing.

In addition, colouring by means of infiltration near the surface (penetration depth: approximately 0.3 mm) is the most frequent type of post-processing performed in order to improve the look and feel of laser-sintered components.