What is a gear?

Basically, a gear is a circular disc with regular notches (serrations) that run the full circumference. It is used to transmit (kinetic) forces to another gear or a chain.

Two or more gears combined together form a gearbox. At the same radius, the wheels act on each other with the same force. If the radii of the gears differ, the acting torques are also of different magnitude. This effect is used for the better utilisation of drive forces.

Types of gears

Spur gear

The spur gear, which is also called cylinder wheel is the most common among the gears. The toothing lies on the circumference of the cylindrical disc. For a spur gear to result from a combination, the axes of the spur gear must be parallel to the counterpart.

The following gearing is possible:

- Axially parallel gear

- Helical gear

- Various curved gearing

- Double helical gearing: undercut & herringbone gearing

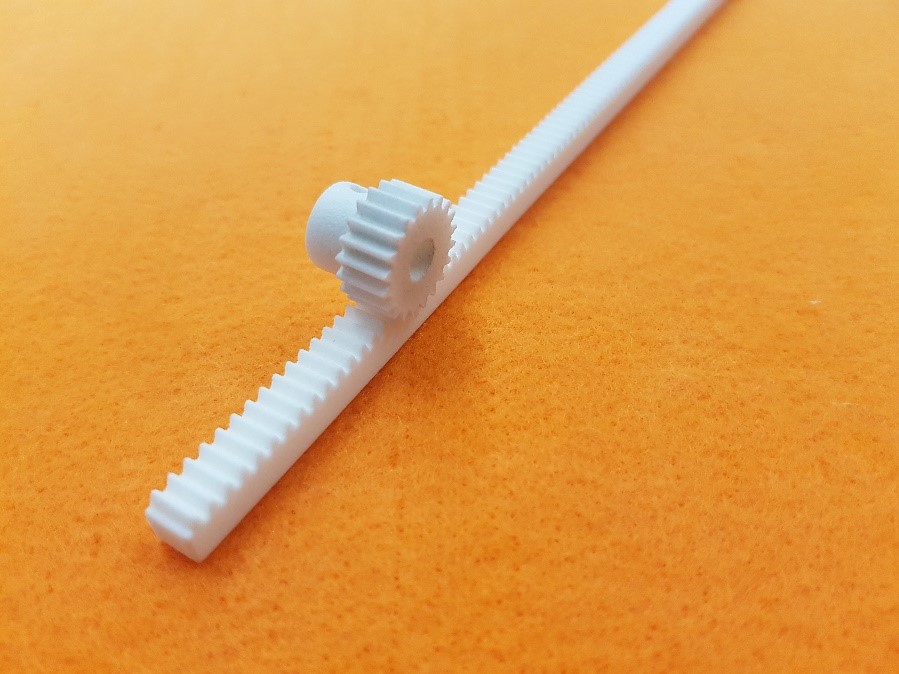

Rack

The rack is a linear machine element with serrations. The clearance space is limited by the length of the rod, which is why a to-and-fro motion usually takes place when using a rack. Together with a spur gear, the combination is called rack gear.

Several racks can be strung together to form a rack rail or cog railway.

Elliptical gear

An elliptical gear consists of non-circular wheels and is unevenly transmitting. While gear transmissions are usually made up of round gears, an elliptical gear is, as mentioned, a non-circular gear. When a normal gear rotates, the connected wheel rotates evenly. For elliptical gears, the associated gears must be identical to each other so that the constant centre distance is taken into account. In a combination of an elliptical gear with a spur gear, a wheel must be mounted on a movable swing axis or, when transmitting, run via a chain or toothed belt that connects the two wheels.

Examples for use

- Chain drive of bicycles

- Weaving machines

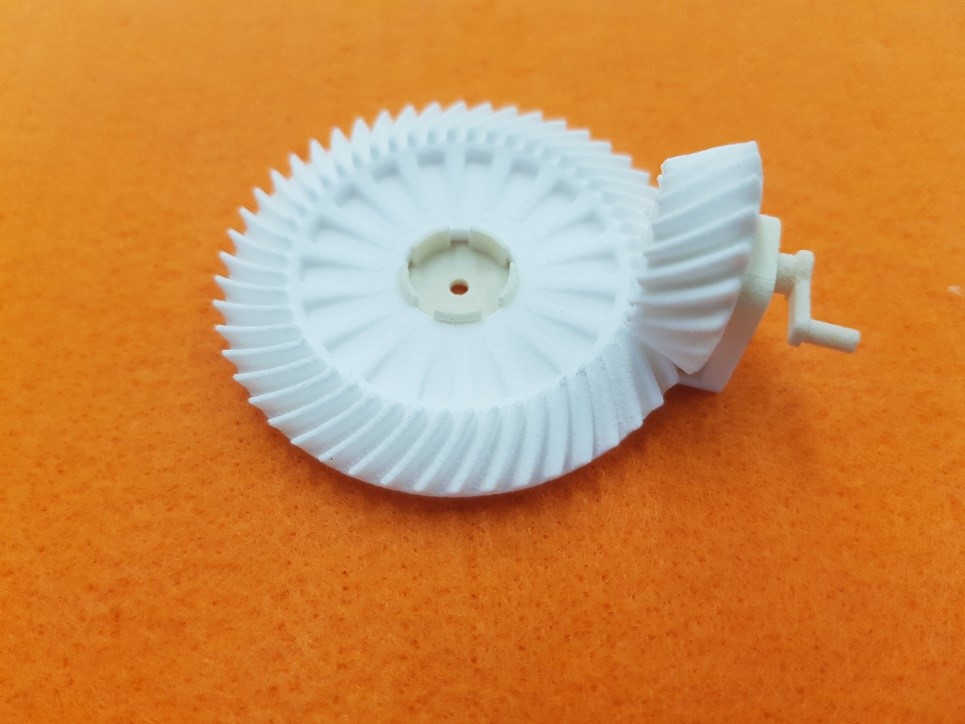

Bevel gear

The axes of bevel gears are usually at an angle of 90° to each other and intersect. With two coupled bevel gears, the tips converge. The toothed lateral surface lies on a truncated cone and most of the teeth run straight to the surface line. In hypoid gear they are curved while generally corresponding to the tooth height profile of an octoid.

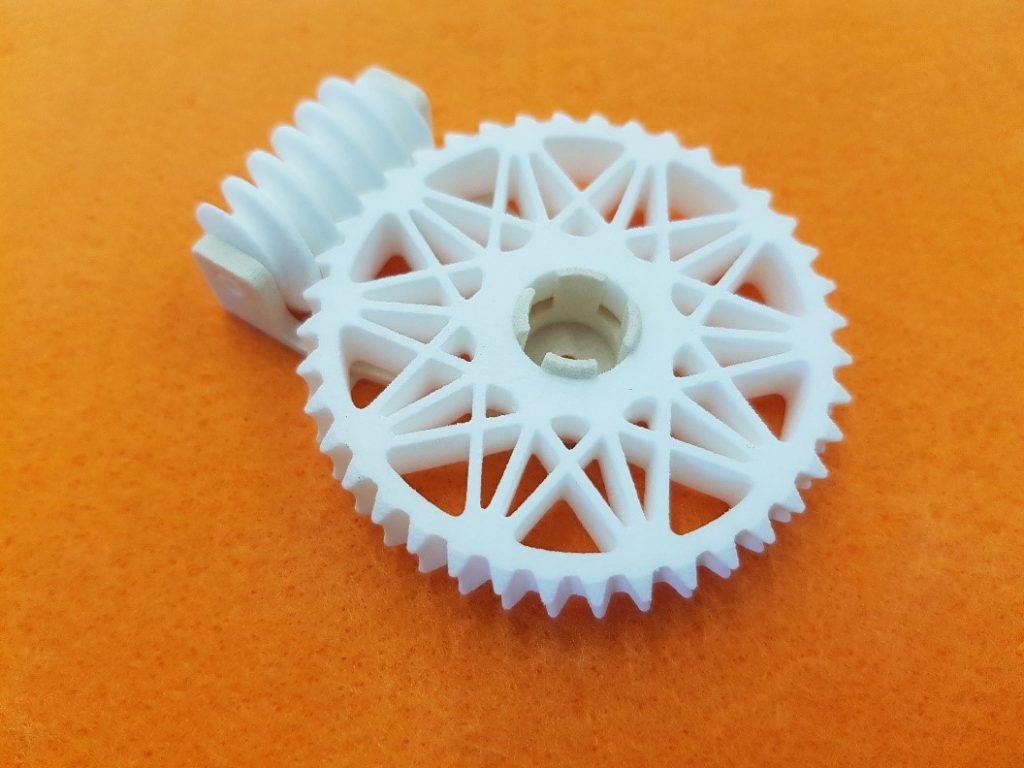

Worm wheel and screw

A worm gear consists of a helical worm screw and a worm wheel. The toothing on the screw are similar to a thread whereby the teeth loop around the cylinder like in a screw. A turn equals a tooth. In the simplest case, the worm wheel can be a spur gear with helical toothing.

Due to the lay out of the lines to be achieved, the tooth flanks of the worm wheel are made hollow so that not just a point contact comes about. The worm gear has a relatively high gear ratio and is at the same time the quietest gear drive.

A possible modification is the globoid screw, which is adapted to the round shape of the worm wheel. Here the cylinder is taper-cut and not cylindrical.

In our online tool, you can calculate the service life of gears made by the 3D printer.

Go to service life calculator for gears

Do you need a gear from the 3D printer, but do not have a CAD file yet? Then you can create your own gear in our configurator and download the CAD file.