Is gas nitrocarburising the best protection for bearing bolts?

Lars Butenschön | 1. April 2022

Corrosion protection of shafts and bearing bolts is especially critical if the bearing position is not to be lubricated. In more and more applications, lubrication of plain bearings is becoming a real problem (e.g. in the construction machinery industry). The frequently used galvanised shafts often turn out to be not resistant enough when used with plain bearings. In search of potential savings in wear-resistant and corrosion-free shaft materials, we carried out and compared extensive tests with various coatings.

On the test rig: various shaft coatings in the salt spray test

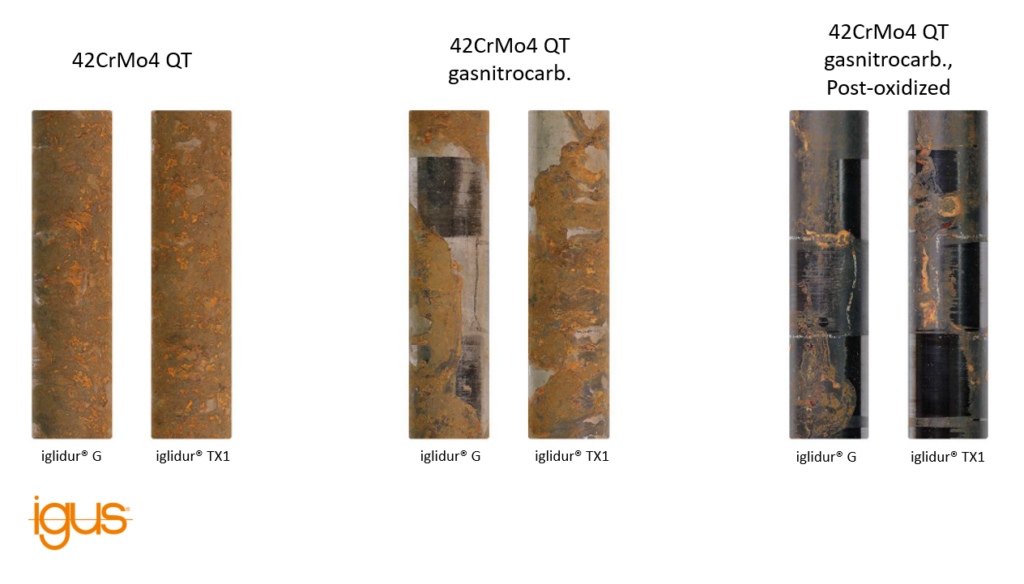

The gold standard of corrosion testing is the so-called salt spray test. Here, the corrosion process is greatly accelerated by spraying salt water into a test chamber. This allows reliable and standardised testing of how susceptible surfaces are to corrosion with comparatively little time expenditure. Bearing bolts made of quenched and tempered 42CrMo4 steel were tested without further treatment, gas nitrocarburised, and gas nitrocarburised with additional post-oxidation. All bearing bolts were “in use” before the salt spray test, so that any running-in marks left by the bearings could also be taken into account. In order to be able to test the effects of the wear or running-in marks of different bearings, two variants were tested in each case. On the one hand those that previously ran with plain bearings made of iglidur® G, and on the other hand shafts that were used in combination with iglidur® TX1. The shafts were stored in the salt spray chamber for 120hrs. and then examined.

A clear result

The result of the salt spray test clearly shows that shafts with gas nitrocarburising and additional post-oxidation offer by far the best protection against corrosion. Single gas nitrocarburised shafts offer only limited protection against corrosion, while bearing bolts without additional surface treatment are subject to severe corrosion. For this reason, the use of gas nitrocarburised and additionally post-oxidised steels is strongly recommended for non-lubricated bearing bolts when used in humid environments.

We would be happy to assist you!

Whether in the selection of the right corrosion protection for shafts and bearing bolts in combination with iglidur® plain bushings or the holistic design of your bearing location. We will support you free of charge from the design stage to the delivery of the finished product. Please contact us!