Interview: Maintenance-free solutions for knife edges in conveyor belts

Marc Preinesberger | 25. May 2021

In this interview, Lars Braun (igus industry manager for the packaging industry) talks about how value engineering and the packaging, food and beverage industries influence product development at igus. In close co-operation with a customer, the maintenance-free knife edge roller for conveyor belts made of durable iglidur materials was developed.

igus develops individual products together with customers

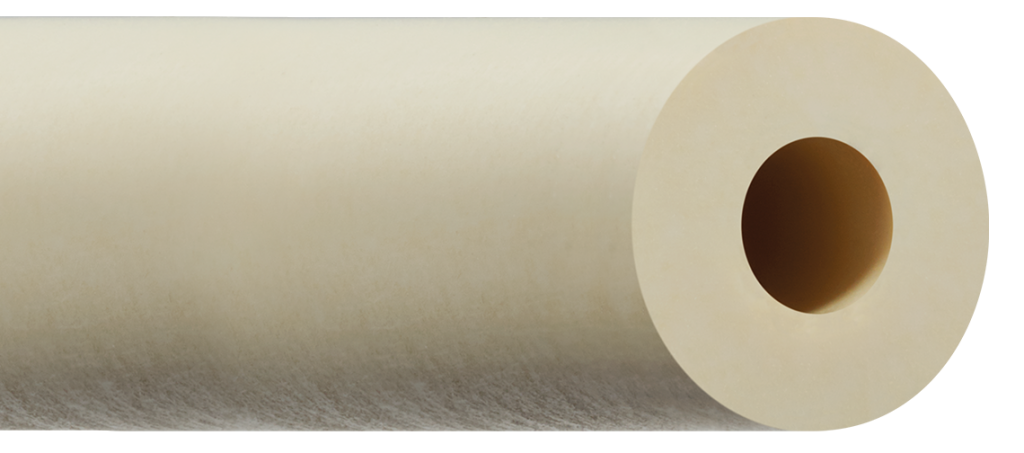

In order to increase the performance of its packaging lines, the company was looking for a belt diverter that could withstand the increasing demands: higher belt speeds, chemicals, moisture and temperatures of up to 100°C. In the igus test laboratory, various approaches were tried out and put through their paces until a suitable product was developed: an injection-moulded iglidur polymer roller, made of a material specifically developed for this application. The maintenance-free knife edge roller for conveyor belts was born. Thanks to the iglidur P210 material, it even exceeded the customer’s service life requirements.

What is value engineering?

First of all, one question needs to be clarified: what is value engineering? In short, value engineering is a structured method of thinking that is used, for example, B. to develop innovations or projects. The focus lies on keeping the value or benefit as high as possible, while using few resources.

More information about our different iglidur knife edge rollers is available here.

You can also obtain our iglidur knife edge rollers in the igus online shop.