Interaction of insulation displacement terminations and cables?

igu-blog-adm | 27. March 2020

In most cases, an installation of insulation displacement termination works smoothly and without special cables. In exceptional cases there may be small hurdles, which we will discuss in more detail today. The interaction of insulation displacement terminations and cables is important.

What is an insulation displacement termination and how does it work?

The technology of the insulation displacement termination is becoming increasingly popular and today’s world of plugs and terminals would be unthinkable without it.

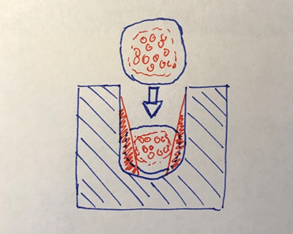

The principle is relatively simple, as you can see in the hand-drawn sketch below.

If a core is connected normally, the insulation must be removed and the now exposed stranded wire must be fitted with a wire end ferrule. The core is then screwed into the termination.

These operations are combined in the insulation displacement termination.

The unprepared core is placed in a so-called core manager. When closing the connector, the cores are pushed past small knives until they reach their end position. These small knives first cut the insulation and then automatically make the permanent connection with the wires of the strand.

The combined work processes result in enormous time savings and the connector is much easier to process. This principle is usually found in connections for the bus and data cable area, in other words, when it comes to smaller cable cross sections.

Any problems with the use of insulation displacement terminations?

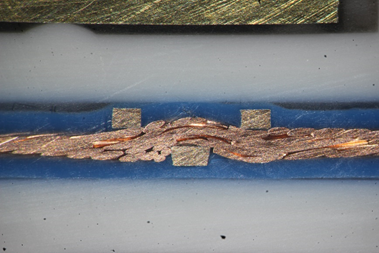

The challenge is not to damage the strand during the cutting process. Only the insulation should be severed. The connection to the blades should be permanent. The expert speaks of a gas-tight connection. A gas-tight connection means that there is no gas between the two materials (cutting strand) and that none can reach them.

This gas would lead to oxidation, resulting in a bad connection. In the worst case a loose contact can occur. The blade must be of very high quality and precise. Each of the current manufacturers has its own concept for this, which is sometimes extremely complex.

Standard strands

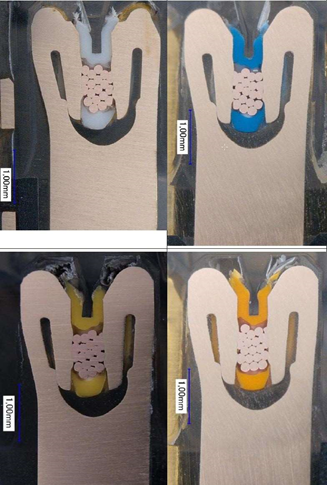

The blades are tested in the laboratories with standard strands and put through their paces in elaborate series of tests for the field with vibration, temperature alternation tests and many more.

The so-called “standard strand” consists of 7 wires for moving cables. However, this does not even cover many cables for industrial use. Other strands are installed there, which the user often does not know. Out of ignorance the user connects them and brings together two high-quality components that are not intended for each other. This can lead to the above mentioned problems with dynamics and temperature fluctuations.

The interaction of insulation displacement terminations and cables is accordingly important.

How can these problems be solved?

The user of the cable or terminal cannot provide a real solution. Only the manufacturers of the components can do this. Cable and connector manufacturers must make contact here and check critical components.

igus is in contact with well-known manufacturers such as Harting, Phoenix Contact and Telegärtner. In the past, the connections of various bus cables could be extensively tested in the company’s own laboratories and qualified for the field of motion.

A very extensive test series took place a few years ago in the area of RJ45 connectors with Harting. For connectors made by Telegärtner, a similar piercing technology was used, which was also elaborately qualified. Here a mandrel is pressed through the core, but this must also form a gas-tight connection.

Safety is important!

We at igus harness thousands of cables a day ourselves and want to provide the customer with a safe product that lasts. For this reason we strive for a close co-operation with different manufacturers. We want to optimally qualify our high-quality cables for their connectors. This means that we go for safety during our own assembly and can also offer a reliable readycable.

Conclusion

Unfortunately, standards often only consider one component. Cables and connectors are standardised. However, customers need the optimal interaction. We ensure this with our partners through such basic research!

Do you need further information? You are welcome to contact us.