igus solutions for injection moulding machines. Tested in igus 3-shift operation.

Christian Schäfer | 15. April 2020

Injection moulding is one of the primary processing methods in plastics processing. It is the most widely used processing method. About one third of all plastics are processed on injection moulding machines.

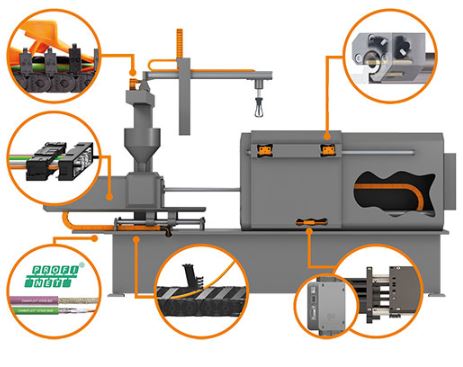

An injection moulding machine usually consists of three main groups, the machine bed, the clamping unit and the injection unit. Energy chain systems, highly flexible cables and bearing technology solutions by igus ensure a long service life of all parts of injection moulding machines.

The use of energy chains on injection moulding machines

Energy chains can be used at different points of the machine. A small part constitutes optics and protection with little movement. A further and continuously moving application option is located on the injection unit. Various cables such as control, servo and motor cables and, depending on the machine type, hydraulic hoses are guided to the injection unit. Energy chains are used to implement the strokes of the injection unit and guide the cables and hoses safely. As a rule, the injection units move horizontally with relatively small strokes (0.3 – 1m).

Another continuously moving area of application for e-chains is at the clamping unit. With the clamping unit, the movement is horizontal in most cases. Here hydraulic hoses but also different cables (control, data and servo cables) are moved. As with the injection unit, the strokes are relatively short (0.5 – 2m). However, due to frequently short cycle times (< 2s) and constant use, the e-chains are moved frequently.

The dimensions of the injection and clamping unit can vary greatly. The basic procedure remains the same in principle, but the dimensions and also the energy chains are different. Depending on the dimensions of the machine, small E2/000 up to E4.1 chains are used.

The easy way to open and close machine guard doors with igus drylin linear guides

The plain bearings sector also offers various applications on the injection moulding machine. For example, drylin N low-profile linear guides are used for opening and closing protective enclosures and covers. Both for the horizontal movement of the protective doors for horizontal injection units and for the vertical movement of the safety housing for vertically arranged injection units. The low-profile linear guides are light and compact and are particularly impressive because they are lubrication-free.

If it should be even lighter, drylin W hybrid roller bearings are used. They provide low displacement forces due to the combination of rolling and sliding.

The benefits at a glance

- Tested in igus 3-shift operation

- Low wear due to specially optimised igus polymers

- Use in high temperatures

- Easy installation due to fast opening and separation of chain links

- Cable-protecting rounded crossbars, especially interesting when using hydraulic hoses

- Special materials are available for special applications

- High product variety for almost every application

- Weight and cost savings through “lightweight design”