How did the TRX come about and is it THE robotics innovation?

Marius Glaue | 7. September 2023

One day after the trade show

It happened near the beginning of the Hannover Messe, not all that long ago. They say that sometimes the best ideas come from a mix of nonsense and a little alcohol. Something like that must have been in play when the idea for the TRX emerged. Two exhausted, thirsty igus employees sat at a hotel bar a little too long after a tough day at the trade show and started talking: “Hey, what would happen if…?” The result would be nothing less than THE next innovation in robotics.

How an idea became a product

One of them was responsible for flexible cables (chainflex®), and the other was working with the round triflex R chain, which could be moved in three dimensions. They wanted to create the perfect product for both areas. The first idea was the telescoping cable, which was quickly rejected as a “nutty idea”. So they thought about how to further optimise the movement of a retraction system with a flexible cable by eliminating components. At the time, there was no alternative to the retraction system on an industrial robot. (In many applications, there still isn’t.)

But something was missing: Something could be adapted to save space and weight, and, most importantly, reduce costs. Why can’t the triflex R energy chain also do the retraction system’s work? “Like a rubber band,” one of them said. The other replied, “Yeah! Just like a rubber band!” With that, they went off to bed, because there was more trade show the next day.

“After the trade show is before the trade show”

There must not have been too much alcohol involved because on the next day of the trade show, both of them remembered the rubber band concept very well, and they decided to present their crazy idea to a developer when they got back to Cologne. Design engineers are not known for their patience with craziness. Their response is generally “What has sales come up with now?” The idea was viewed critically, but not dismissed as impossible.

As we all know, after the trade show is before the trade show, so they decided to give the idea a chance. It did provide a potential innovation for next year’s trade show, and there was a whole year of development time. Perfect. One of the two employees from the beginning of the story recently told me that “innovation by elimination” was one idea behind the TRX: “Develop something new and try to get rid of as much as possible.”

But, as with every good story, the devil was in the details. You couldn’t simply repurpose an existing, established TRE.60.087.0.B by putting a rubber band through it. The high-tensile-strength core element that can be moved in three dimensions is one of the triflex R TRE chain’s special features and strengths and cannot simply be replaced.

The development and sales team decided to attempt a completely new design, which has much the same look as the existing TRE chain, so the two can be connected.

After countless meetings and tests, the TRXE was presented as a design study at the 2021 Hannover Messe.

What the TRX was to achieve as a robotics innovation

In the world of automation technology, reliable energy supply plays a crucial role. Companies are constantly looking for innovations that are both durable and efficient. In this context, a “crazy idea” became a robotics innovation. It was groundbreaking and became especially popular in the area of handling packages.

TRX structure + durability + efficiency

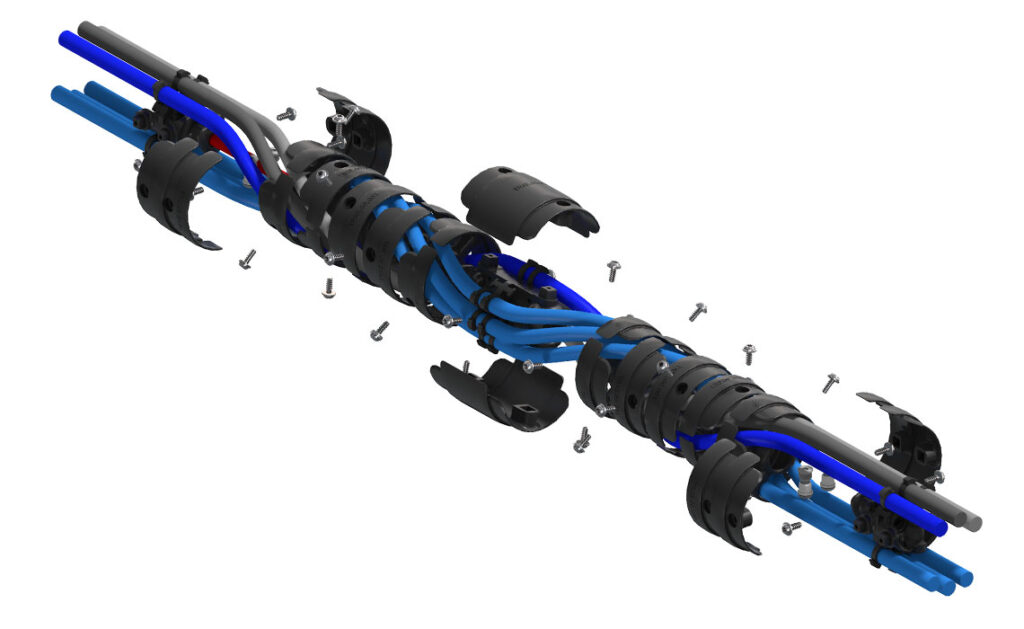

The TRX consists of special modules that allow the energy chain to bend in any direction. This increases flexibility and prevents unnecessary tension or kinks in the cables. Flexibility is not limited to 3D movement; the wobbly chain link shape also allows telescoping movement. The rubber band in the middle of the TRX ensures that the chain contracts again.

Long service life and freedom from maintenance: One of the greatest strengths of the TRX is its long service life. The energy chain is made of high-quality, wear-resistant plastic, ensuring reliable function even under extreme conditions. The small number of add-on parts (the retraction system has been eliminated) greatly reduces maintenance costs.

Energy efficiency and safety: The TRX is also energy-efficient. The optimised design minimises friction, wear, and especially weight, reducing energy consumption. This benefits both economy and ecological performance.

Conclusion

Conclusion: The igus TRX is undoubtedly a milestone in energy chain development. Its innovative design, durability, energy efficiency, and simplicity make it a future-oriented solution for energy supply to robots and industry in general. The TRX reduces maintenance costs in the area of handling packages and extends service life. The igus TRX proves that relaxed banter can return a high-tech innovation. You just have to believe in yourself.

Sources:

Telescopic triflex R TRX | 3D movements | igus®

https://www.igus.eu/product/21456